Phosphorus-free acidic cleaning agent, preparation method and application thereof

A cleaning agent, phosphoric acid technology, applied in the field of cleaning agents, to achieve the effect of enhanced removal, strong descaling ability, and scientific and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

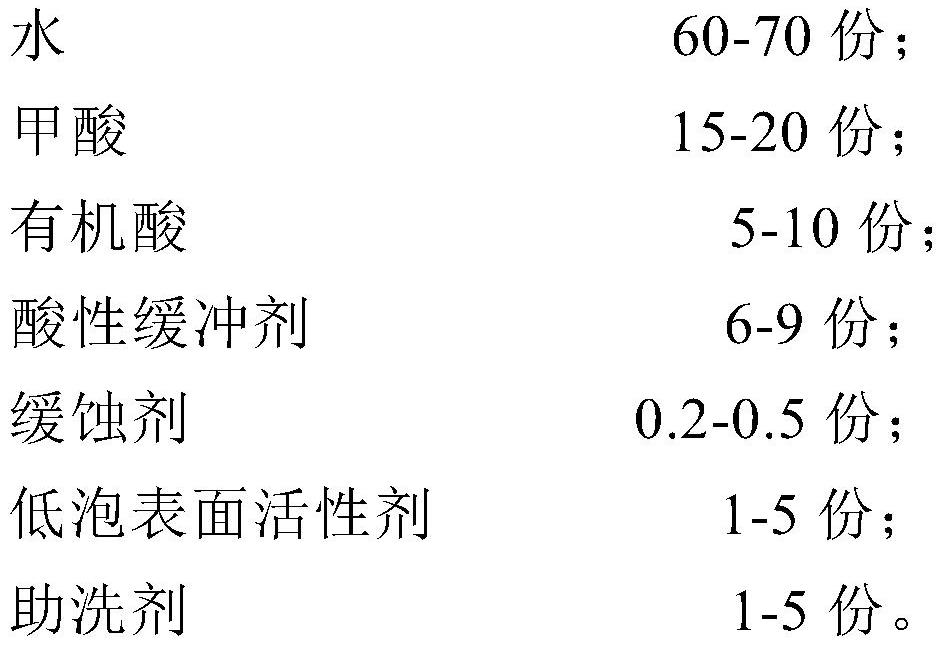

[0046] This embodiment discloses a kind of non-phosphoric acid cleaning agent, comprises each component of weight ratio as follows:

[0047]

[0048] The organic acid: methylsulfonic acid, sulfamic acid; acid buffer: glycolic acid, lactic acid; corrosion inhibitor: benzotriazole; low-foaming surfactant: fatty acid methyl ester ethoxylate; builder : Alcohol ether solvent, acrylic acid / maleic acid copolymer.

[0049] The preparation method of this embodiment without phosphoric acid cleaning agent:

[0050] 1. Add water, formic acid, organic acid, acid buffer and mix well

[0051] 2. Add low-foaming surfactant and builder and stir evenly

[0052]3. Add corrosion inhibitor and stir evenly

[0053] The present embodiment has no phosphoric acid cleaning agent physical and chemical index:

[0054] Appearance: Light yellow to brown yellow transparent liquid

[0055] Density: 1.086g / cm 3

[0056] pH: 0.98

[0057] Titration number (10ml solution): 27.6ml

[0058] Boiling po...

Embodiment 2

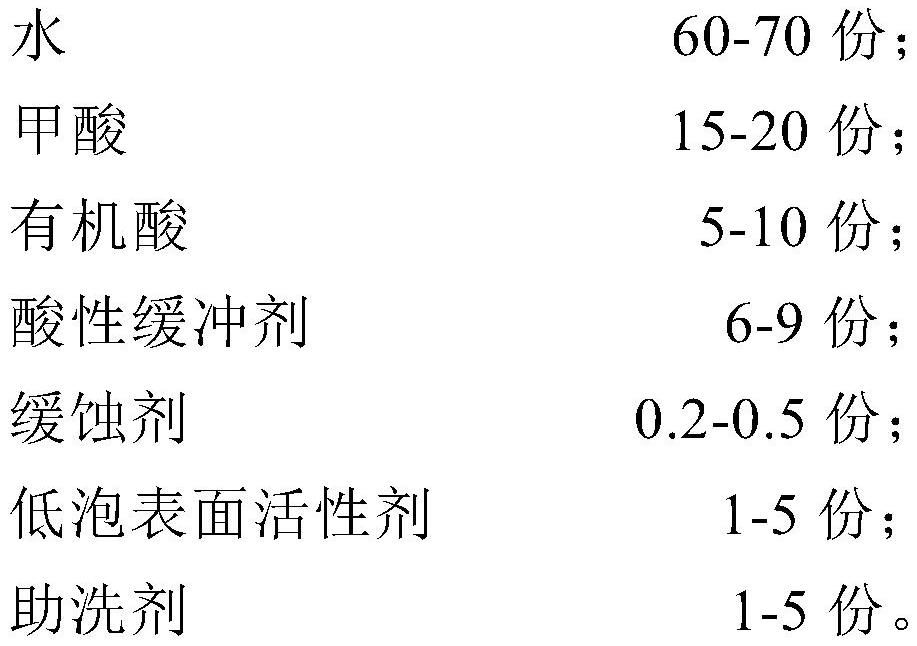

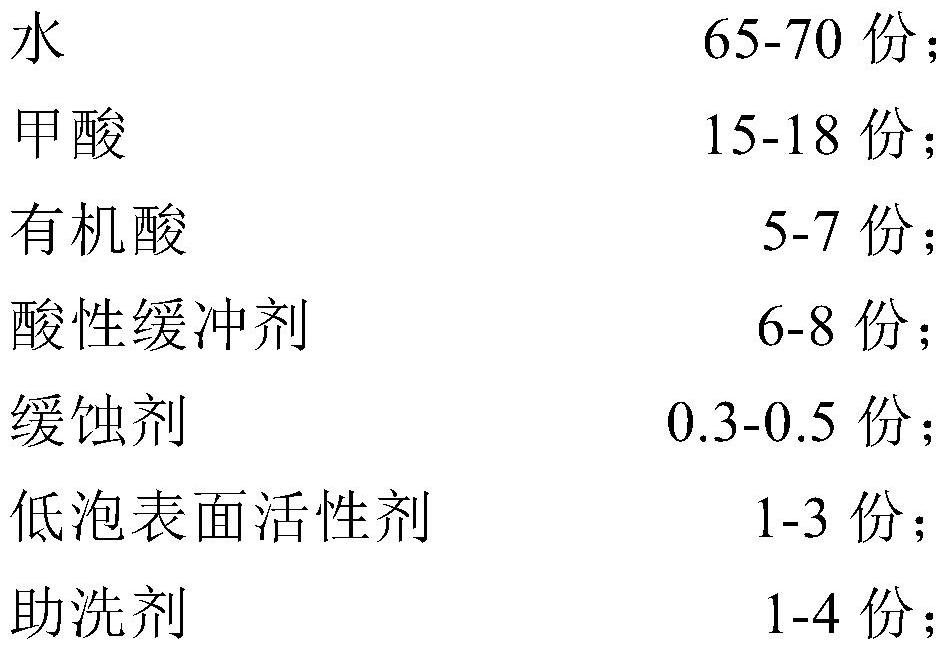

[0062] This embodiment discloses a kind of non-phosphoric acid cleaning agent, comprises each component of weight ratio as follows:

[0063]

[0064] Described organic acid: citric acid; Acidic buffer: glycolic acid; Corrosion inhibitor: benzotriazole; Low-foaming surfactant: fatty alcohol polyoxyethylene ether, alkyl glycoside; Builder: alcohol ether solvent, JFC.

[0065] The preparation method of this embodiment without phosphoric acid cleaning agent:

[0066] 1. Add water, formic acid, organic acid, acid buffer and mix well

[0067] 2. Add low-foaming surfactant and builder and stir evenly

[0068] 3. Add corrosion inhibitor and stir evenly

[0069] The present embodiment has no phosphoric acid cleaning agent physical and chemical index:

[0070] Appearance: Light yellow to brown yellow transparent liquid

[0071] Density: 1.088g / cm 3

[0072] pH: 0.76

[0073] Titration number (10ml solution): 29ml

[0074] Boiling point: 100°C

[0075] Foam (3% aqueous solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com