Environment-friendly automobile detergent and preparation method thereof

A detergent and environment-friendly technology, applied in the field of environment-friendly car detergent and its preparation, can solve the problems of unsatisfactory use effect, adverse environmental impact, slow decomposition of detergent, etc., to improve the reaction performance and the uniformity of dispersion, Strong activation performance and enhanced degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

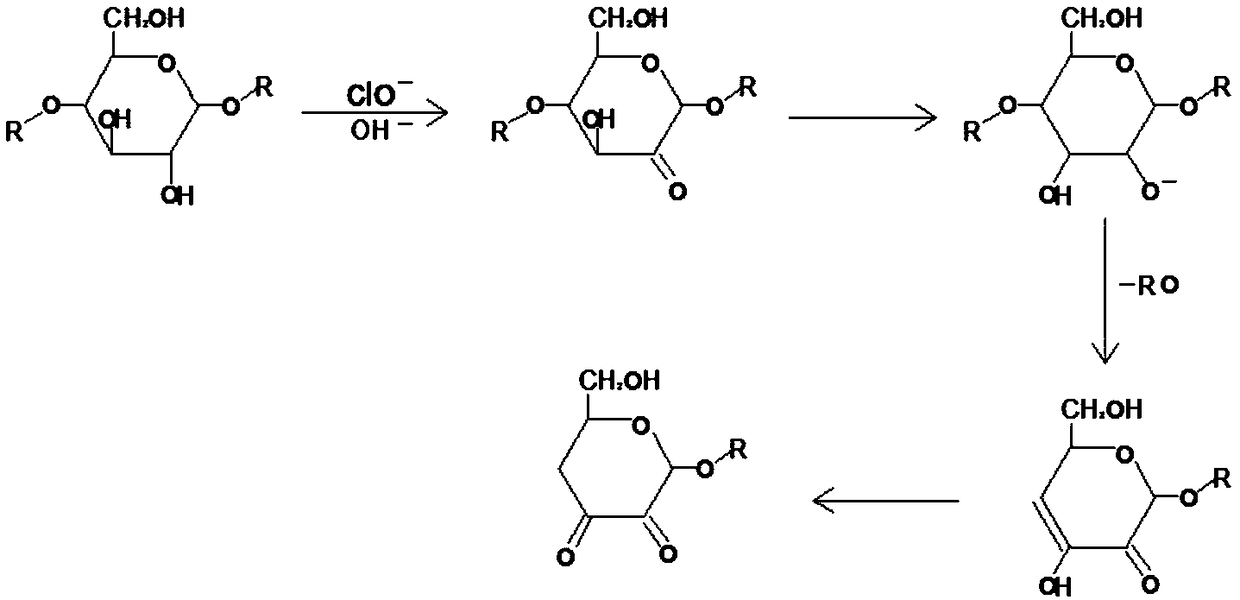

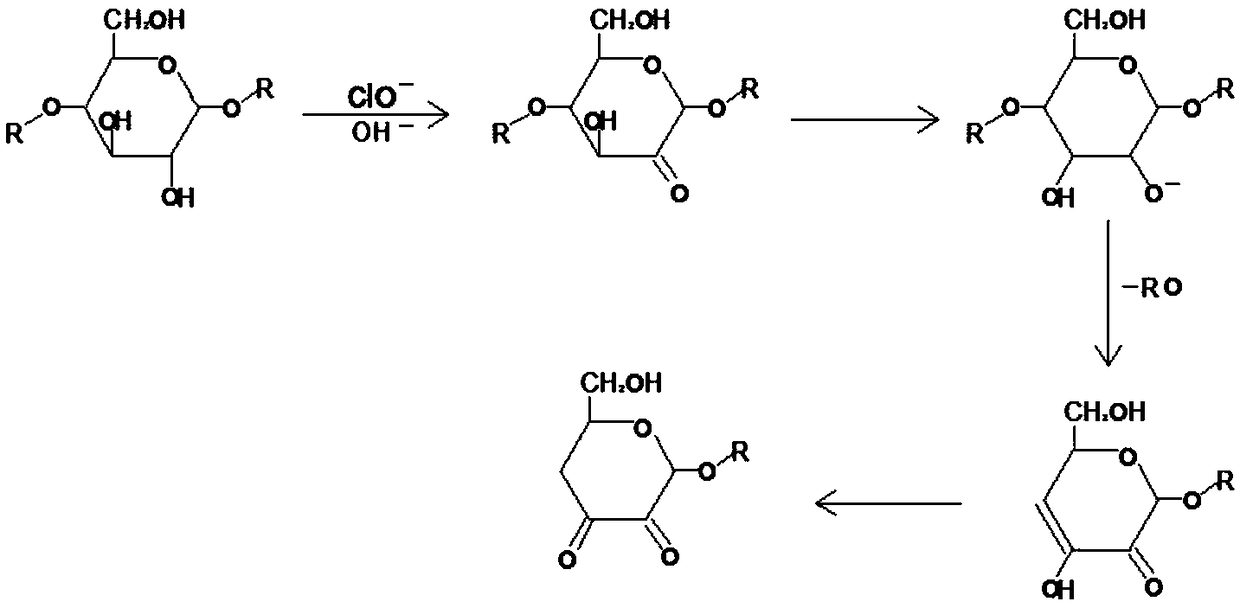

Method used

Image

Examples

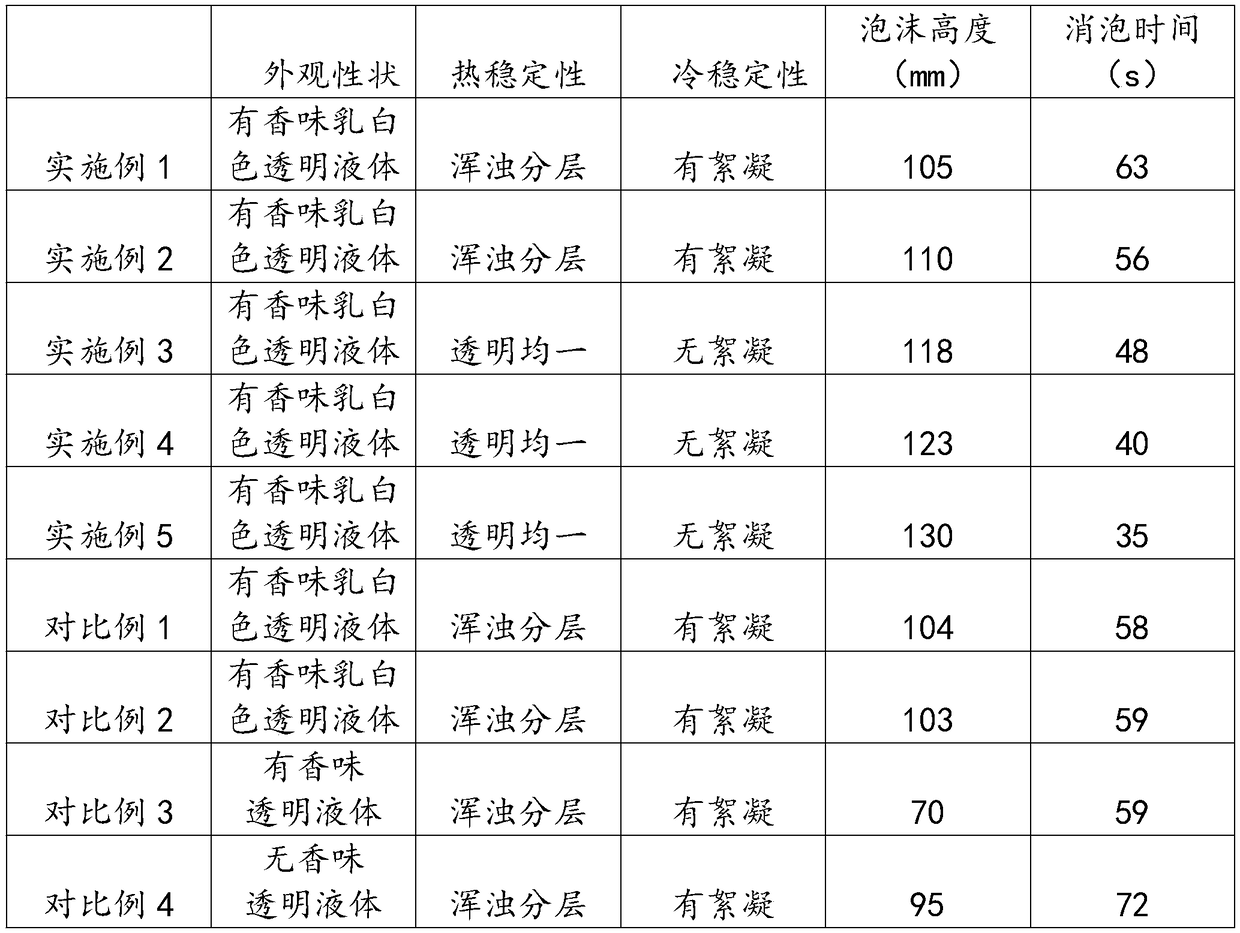

Embodiment 1

[0042] An environment-friendly car detergent, comprising the following raw materials by weight: 30 parts of sodium lauryl ether sulfate, 25 parts of modified nano-microcrystalline cellulose, 25 parts of polyoxyethylene fatty acid esters, 15 parts of lauryl diacetate Mebyl ammonium oxide, 10 parts of potassium sorbate, 20 parts of sodium tripolyphosphate, 15 parts of silicone oil emulsion, 5 parts of ethylenediamine phosphate, 1 part of fragrance, 10 parts of diethylene triamine pentaacetate iron-sodium complex, 50 parts parts deionized water;

[0043] Described environment-friendly car detergent is made by following method:

[0044] (1) Mix sodium lauryl ether sulfate, potassium sorbate and lauryldimethylbenzyl ammonium oxide, add it into a beaker filled with deionized water, heat to 80°C, and stir at a constant speed for 30min at this temperature, Make A liquid spare;

[0045] (2) Add sodium tripolyphosphate, modified nano-microcrystalline cellulose and ferric-sodium diethy...

Embodiment 2

[0052] An environment-friendly car detergent, comprising the following raw materials by weight: 35 parts of sodium lauryl ether sulfate, 26 parts of modified nano-microcrystalline cellulose, 30 parts of polyoxyethylene fatty acid esters, 18 parts of lauryl diacetate Mebyl ammonium oxide, 12 parts of potassium sorbate, 22 parts of sodium tripolyphosphate, 17 parts of silicone oil emulsion, 6 parts of ethylenediamine phosphate, 2 parts of essence, 12 parts of diethylene triamine pentaacetate iron-sodium complex, 55 parts parts deionized water;

[0053] Described environment-friendly car detergent is made by following method:

[0054] (1) Mix sodium lauryl ether sulfate, potassium sorbate and lauryldimethylbenzyl ammonium oxide, add it into a beaker filled with deionized water, heat to 80°C, and stir at a constant speed for 30min at this temperature, Make A liquid spare;

[0055] (2) Add sodium tripolyphosphate, modified nano-microcrystalline cellulose and ferric-sodium diethyl...

Embodiment 3

[0062] An environment-friendly car detergent, comprising the following raw materials by weight: 40 parts of sodium lauryl ether sulfate, 30 parts of modified nano-microcrystalline cellulose, 35 parts of polyoxyethylene fatty acid esters, 21 parts of lauryl diacetate Mebyl ammonium oxide, 16 parts of potassium sorbate, 26 parts of sodium tripolyphosphate, 21 parts of silicone oil emulsion, 7 parts of ethylenediamine phosphate, 3 parts of essence, 16 parts of diethylene triamine pentaacetate iron-sodium complex, 60 parts parts deionized water;

[0063] Described environment-friendly car detergent is made by following method:

[0064] (1) Mix sodium lauryl ether sulfate, potassium sorbate and lauryldimethylbenzyl ammonium oxide, add it into a beaker filled with deionized water, heat to 80°C, and stir at a constant speed for 30min at this temperature, Make A liquid spare;

[0065] (2) Add sodium tripolyphosphate, modified nano-microcrystalline cellulose and ferric-sodium diethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com