Production process for preparing dimethyl sulfate by composite acid through catalytic dehydration

A dimethyl sulfate, catalytic dehydration technology, applied in the direction of sulfuric acid ester preparation, organic chemistry, etc., can solve the problems of high consumption of methanol and sulfuric acid, the output does not reach the efficiency level, serious production pollution, etc., to reduce the unit consumption of methanol, Increase market competitiveness and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

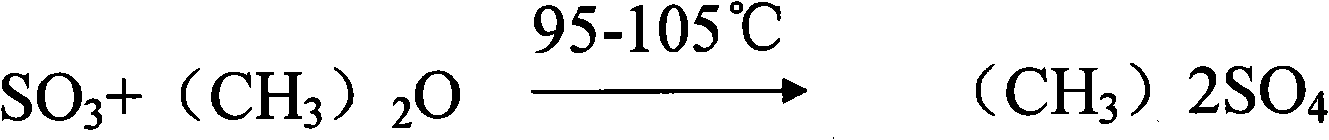

[0012] The implementation of the present invention is to use a pump to press sulfuric acid and phosphoric acid to the high-level tank, prepare a qualified compound acid according to a certain ratio, put it into the etherification reaction kettle, and then vaporize the metered methanol and pass it into the etherification reaction kettle , dehydration reaction under certain conditions to generate dimethyl ether gas, after three-stage purification, it is sent to the esterification tower, and at a certain temperature, it reacts with dimethyl sulfate rich liquid that has absorbed sulfur trioxide to generate dimethyl sulfate Crude product, the qualified dimethyl sulfate crude product is delivered to refining station and carries out vacuum distillation and obtains qualified dimethyl sulfate finished product.

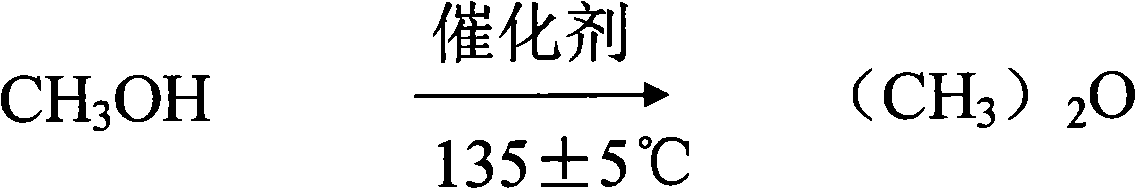

[0013] (1) Methanol catalytic dehydration

[0014]

[0015] Methanol gas enters the tank from the bottom of the etherification reaction tank and fully bubbles into contact w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com