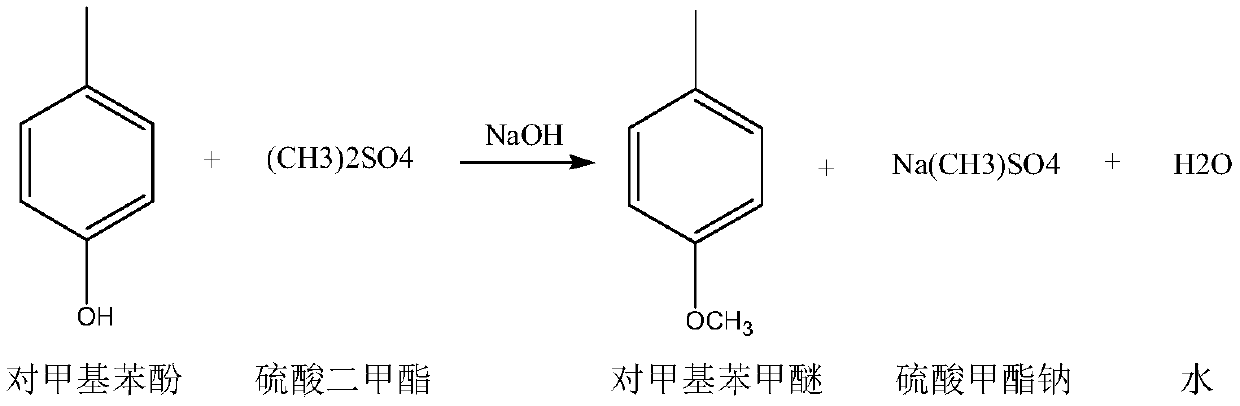

Preparation method of 4-methylanisole

A technology for p-methyl anisole and p-cresol is applied in the field of preparation of fine chemical intermediate p-methyl anisole, and can solve the problems of high cost, high waste water, low utilization rate of dimethyl sulfate, and the like, Achieve the effect of high utilization rate and zero discharge of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

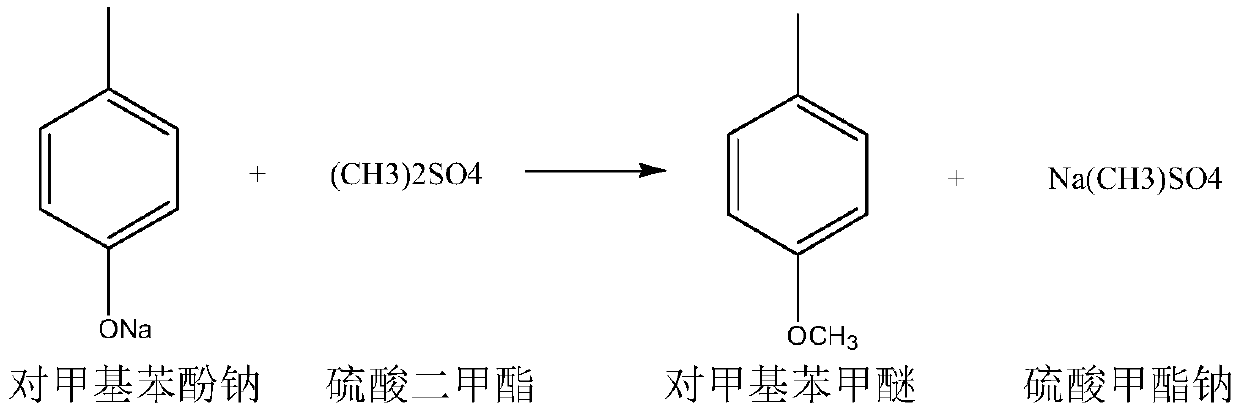

Method used

Image

Examples

Embodiment 1

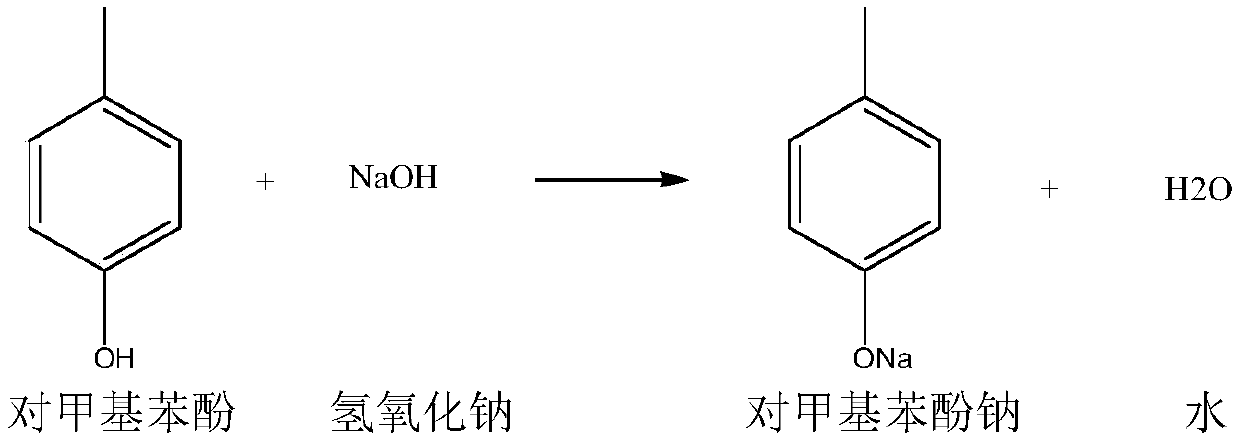

[0042] Neutralization reaction:

[0043] The p-cresol dropped into in the 1000ml four-neck flask with thermometer, stirring paddle, nitrogen pipe, recovery condenser: 100.0g (content: 99.1%, 0.9176mol), dehydrated alcohol: 600ml, open nitrogen protection, Set nitrogen flow rate: 0.5l / min. The outer wall of the four-necked flask is cooled with cooling water, and the inner temperature is controlled not to exceed 35° C. Slowly add sodium hydroxide: 37.5 g (0.9375 mol) into the four-necked flask from the thermometer mouth (pull out the thermometer). After feeding, the reaction was stirred for 1.0 hour. After the reaction is completed, the outer wall of the four-neck flask is heated with 85-90°C hot water, and the ethanol is continuously distilled out under the protection of nitrogen. In the later stage of distillation, the outflow velocity of ethanol will become smaller and smaller. When the outflow of ethanol is very small, vacuum recovery is carried out, and the vacuum degree...

Embodiment 2

[0053] Neutralization reaction:

[0054] 100.0 g (content: 99.1%, 0.9176 mol) of p-cresol dropped into a four-necked flask with a thermometer, stirring paddle, nitrogen pipe, and recovery condenser in 1000 ml, anhydrous n-butanol: 600 ml, nitrogen Protection, set nitrogen flow rate: 0.5l / min. The outer wall of the four-necked flask is cooled with cooling water, and the inner temperature is controlled not to exceed 35° C. Slowly add sodium hydroxide: 37.5 g (0.9375 mol) into the four-necked flask from the thermometer mouth (pull out the thermometer). After feeding, the reaction was stirred for 1.0 hour. After the reaction is completed, the outer wall of the four-necked flask is heated with an electric heating mantle, and the vacuum recovery is carried out under the protection of nitrogen, and the vacuum degree is gradually increased. Finally, the internal temperature is controlled to be less than 100°C, and the vacuum degree is greater than -0.08MPa to recover n-butanol to dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com