Preparation technique of 1,6-dimethoxynaphthalene

A dimethoxynaphthalene, a preparation technology, applied in 1 field, can solve the problems such as difficult recovery of solvent methanol, high cost, expensive acetone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

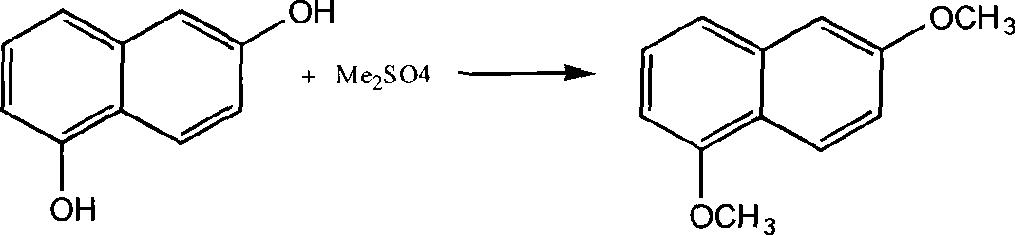

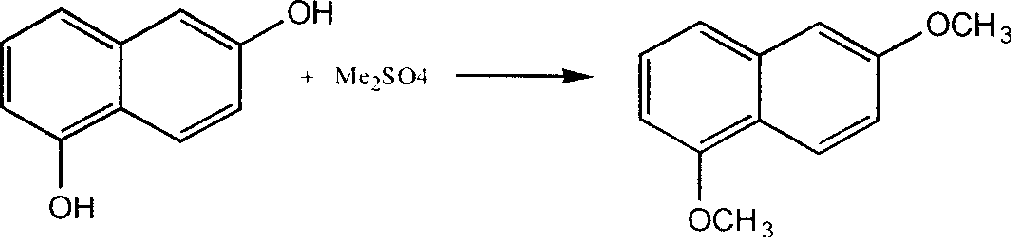

Image

Examples

Embodiment 1

[0023] Add 20g of 1,6-dihydroxynaphthalene, 102g of petroleum ether (boiling point 60-90°C), 99g of NaOH aqueous solution with a NaOH content of 16%, 1g of hydrosulfite, 0.5g of tetramethylammonium chloride, and drop Add 26g Me 2 SO 4 (15 minutes to finish dripping). Heated to 55-60°C, reacted for 1h. Add 49g NaOH content then and be the NaOH aqueous solution of 16%, dropwise add 20g Me 2 SO 4 (After 15 minutes of dripping), add to 55-60°C, and react for 4 hours.

[0024] Then separate the liquid in a separatory funnel while it is hot, take out the upper oil layer, pour it into a beaker, stir it magnetically, cool it down to 0-5°C in an ice-water bath (keep for 1h), and then filter to obtain yellow crystals of 1,6-dimethoxy naphthalene. Yield 70%, purity 98.6%.

Embodiment 2

[0026] Add 20g 1,6-dihydroxynaphthalene, 150g petroleum ether (boiling point 60-90°C), 115g NaOH aqueous solution with 16% NaOH content, 0.5g hydrosulfite, 1g tetramethylammonium chloride, drop Add 32gMe 2 SO 4 (15 minutes to finish dripping). Heated to 55-60°C, reacted for 0.5h. Add 55g NaOH content then and be the NaOH aqueous solution of 16%, dropwise add 24g Me 2 SO 4 (After 15 minutes of dripping), add to 55-60°C, and react for 7 hours.

[0027] Then separate the liquid in a separatory funnel while it is hot, take out the upper oil layer, pour it into a beaker, stir it magnetically, cool it down to 0-5°C in an ice-water bath (keep for 1h), and then filter to obtain yellow crystals of 1,6-dimethoxy naphthalene. Yield 72%, purity 98.3%.

Embodiment 3

[0029] Operate in the same manner as in Example 2, but replace tetramethylammonium chloride with 0.5g octadecyltrimethylammonium chloride, as a result, yellow crystal 1,6-dimethoxynaphthalene is obtained, yield 71.2%, purity 98.1% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com