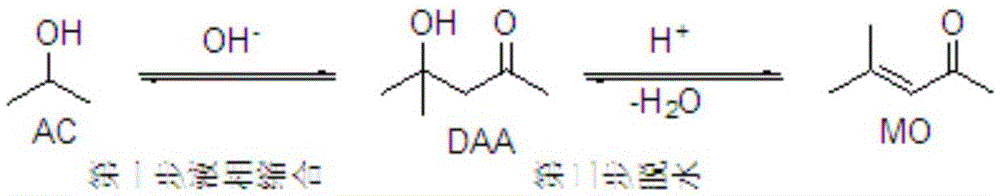

Preparation method of polymer catalyst for acetone condensation

A catalyst and polymer technology, applied in the field of polymer catalyst preparation, can solve the problems of poor thermal stability, low specific surface area, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

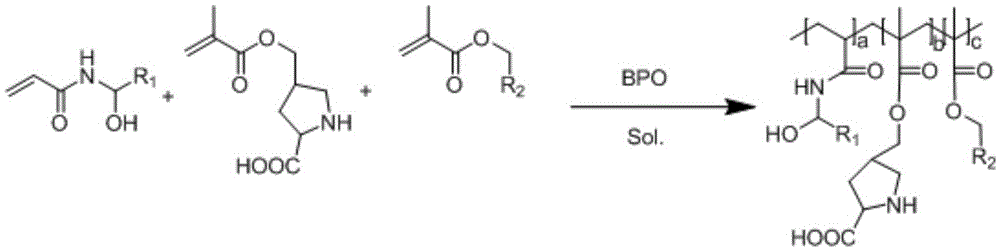

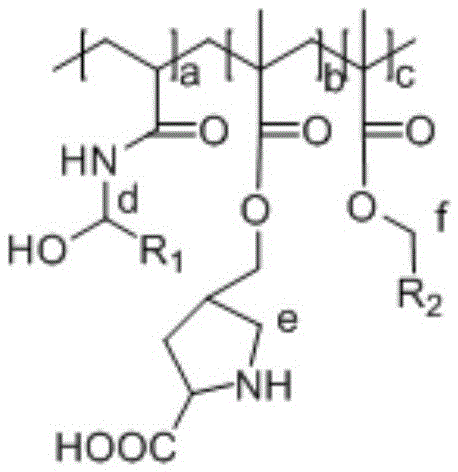

Method used

Image

Examples

Embodiment 1

[0035] Add 1.6988 g of N-methylol acrylamide, 0.2985 g of 2-methyl-2-acrylic acid-4-L-proline methyl ester, and 2-methyl-2-acrylic acid-4- Piperidine methyl ester 0.0855g, initiator BPO0.0460g and solvent DMSO10mL, stirred to dissolve and deoxygenated. The reaction was carried out in an oil bath at 75°C for 12 hours. After the reaction, the product was precipitated with 100 mL of anhydrous tetrahydrofuran as a precipitant, centrifuged, and the precipitate was placed in a vacuum oven at 50°C to dry for 12 hours to obtain catalyst PNL-I1.3795g. 66.23%, where a:b:c=36:3:1.

Embodiment 2

[0037] Add 1.3213 g of N-methylol acrylamide, 0.2985 g of 2-methyl-2-acrylic acid-4-L-proline methyl ester, and 2-methyl-2-acrylic acid-4- 0.0855 g of piperidine methyl ester, 0.0368 g of initiator BPO and 15 mL of solvent MA were stirred and dissolved, and oxygen was removed. The reaction was carried out in an oil bath at 65°C for 10 hours. After the reaction, the product was precipitated with 150 mL of anhydrous tetrahydrofuran as a precipitant, centrifuged, and the precipitate was placed in a vacuum oven at 50°C for 12 hours to dry to obtain 1.2686g of catalyst PNL-II. The preparation yield 74.39%, where a:b:c=28:3:1.

Embodiment 3

[0039] Add 0.9438 g of N-methylol acrylamide, 0.2985 g of 2-methyl-2-acrylic acid-4-L-proline methyl ester, and 2-methyl-2-acrylic acid-4-methyl ester into the pressure-resistant reaction flask. 0.0855 g of piperidine methyl ester, 0.0276 g of initiator BPO and 20 mL of solvent MA were stirred and dissolved, and oxygen was removed. The reaction was carried out in an oil bath at 55°C for 12 hours. After the reaction was completed, the product was precipitated with 200 mL of anhydrous tetrahydrofuran as a precipitant, centrifuged, and the precipitate was placed in a vacuum oven at 50°C to dry for 12 hours to obtain a catalyst PNL-III 0.9438 g, with a preparation yield 71.08%, where a:b:c=20:3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com