Method used for preparing methyl acetate via carbonylation of dimethyl ether

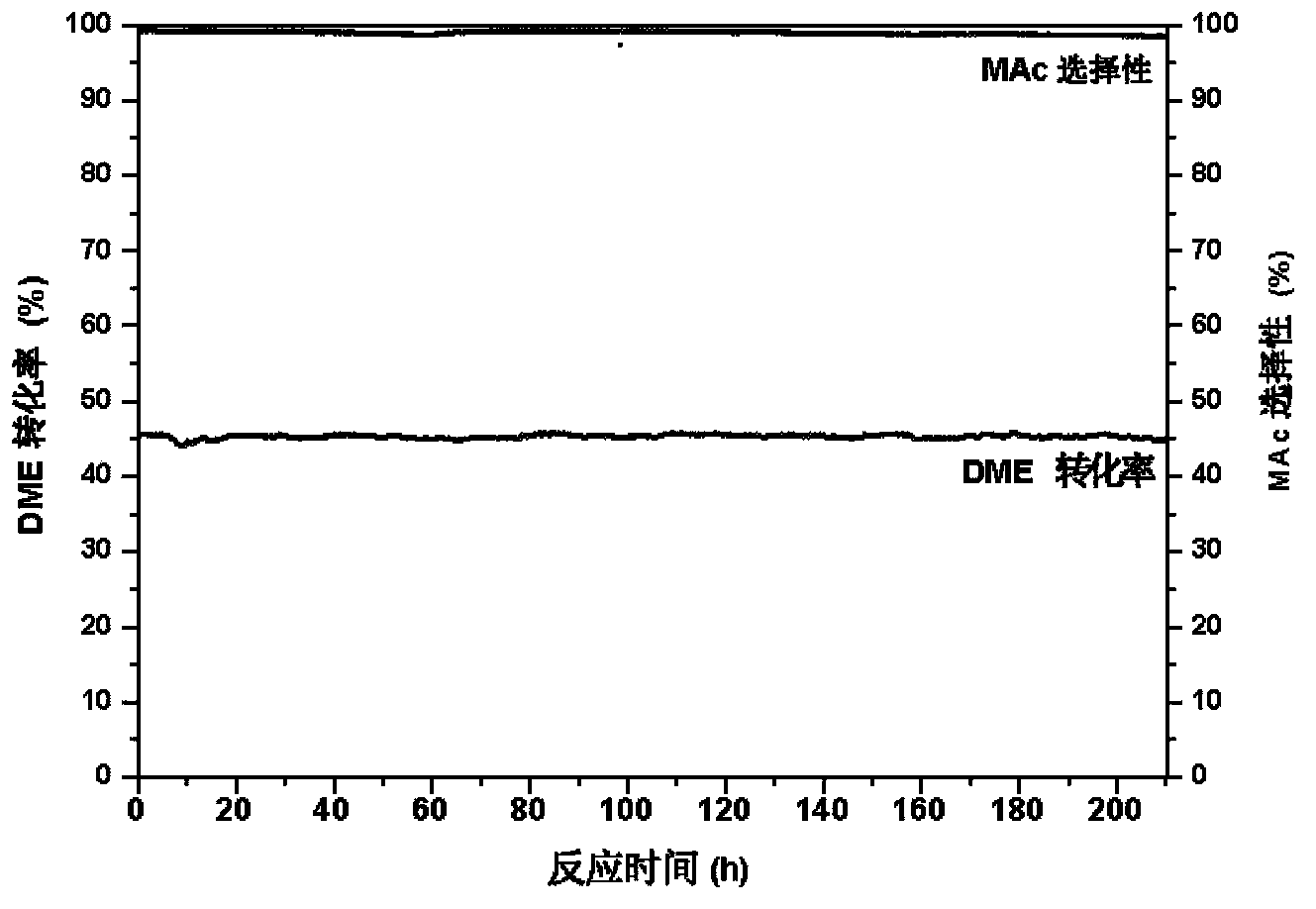

A technology of methyl acetate and dimethyl ether, which is applied in the field of catalytic chemistry, can solve problems such as difficult industrial production, difficult control, and uneven temperature distribution of the catalyst bed, and achieve the effects of improving selectivity, prolonging catalyst life, and avoiding hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 catalyst

[0030] The catalyst is represented by n% M / S, where:

[0031] Molecular sieves: S = mordenite (MOR), ferrierite (FER)

[0032] Heteroatoms: M = iron (Fe), gallium (Ga);

[0033] Loading metal: M = iron (Fe), copper (Cu), silver (Ag), rhodium (Rh), platinum (Pt), palladium (Pd), cobalt (Co), iridium (Ir);

[0034] n=the mass percentage of the metal in the total weight of the catalyst×100; the metal in the supported catalyst is in an oxidation state, and the content is represented by elemental metal.

[0035] 1.1 Synthesis of sodium mordenite

[0036] Dissolve 19 grams of NaOH into 40 ml of deionized water, then add a certain amount of sodium aluminate or a mixture of sodium aluminate + iron nitrate or sodium aluminate + gallium oxide, and stir until completely dissolved. Add 650ml of water to the resulting solution for dilution, then add a certain amount of SiO2 powder and stirred for 30 minutes. The resulting material was ...

Embodiment 2

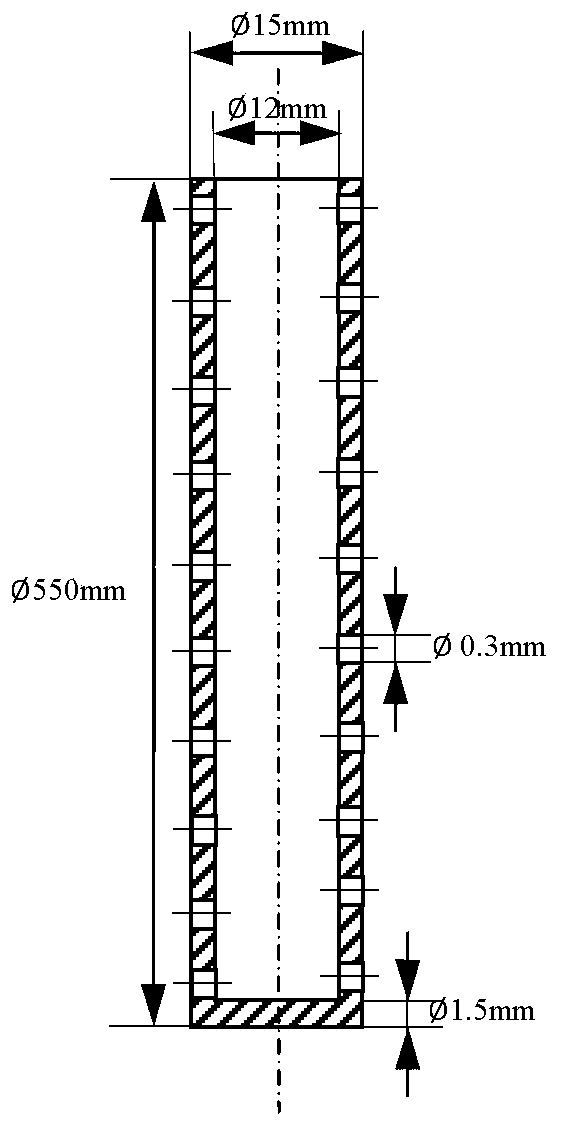

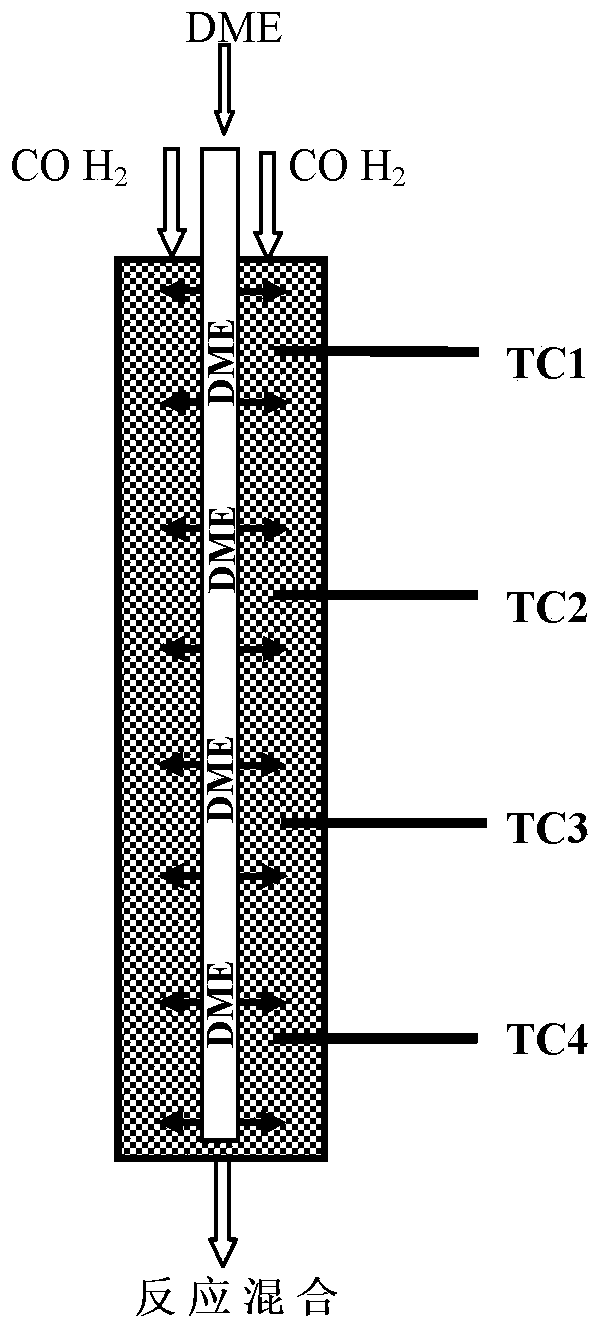

[0060] Embodiment 2. Catalyst pretreatment and reaction

[0061] 2.1 Conventional pretreatment of catalyst

[0062] At the beginning of the investigation, the catalyst was activated at 550°C in a nitrogen atmosphere for 4 hours, then the temperature of the bed was lowered to the reaction temperature, and a certain proportion of dimethyl ether was introduced, and the mixed gas of carbon monoxide and hydrogen was pressurized and reacted. The reactor is heated by an electric furnace, and the reaction temperature is determined by a thermocouple inserted into the catalyst bed.

[0063] 2.2 Pyridine pretreatment of mordenite

[0064] When the mordenite is used as the catalyst, the catalyst can be subjected to pyridine adsorption pretreatment before the reaction. The catalyst was activated at 550°C in a nitrogen atmosphere for 4 hours, then the temperature of the bed was lowered to 300°C, and gaseous pyridine diluted with nitrogen was introduced for adsorption. After 1 hour of ads...

Embodiment 3

[0065] Embodiment 3. the analytical method of product

[0066] The starting materials and the resulting products were analyzed using an Agilent 7890A gas chromatograph. The chromatograph is equipped with dual detectors FID and TCD, and has a ten-way valve, which allows the products to enter the packed column and capillary column respectively at the same time. The hydrogen flame detector detects hydrocarbons, alcohols and ethers in the product, and the thermal conductivity detector detects carbon monoxide and hydrogen in the raw materials and products. Data were processed with Agilent's Chemstation software.

[0067] The specific chromatographic conditions of Agilent are as follows:

[0068] Chromatography: Agilent 7890A

[0069] FID column: HP-PLOT-Q 19091S-001, 50m x 0.2mm (inner diameter), 0.5μm film thickness

[0070] Carrier gas: helium, 2.5ml / min

[0071] Oven temperature: 35°C for 5 minutes

[0072] 35-150°C, 5°C / min

[0073] 150℃ for 10min

[0074] Inlet: Split ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com