Method for treating waste water containing ammonia and nitrogen

A treatment method and wastewater technology, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high operating costs, large consumption of chemicals, and inability to form resources for recycling Use of secondary pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

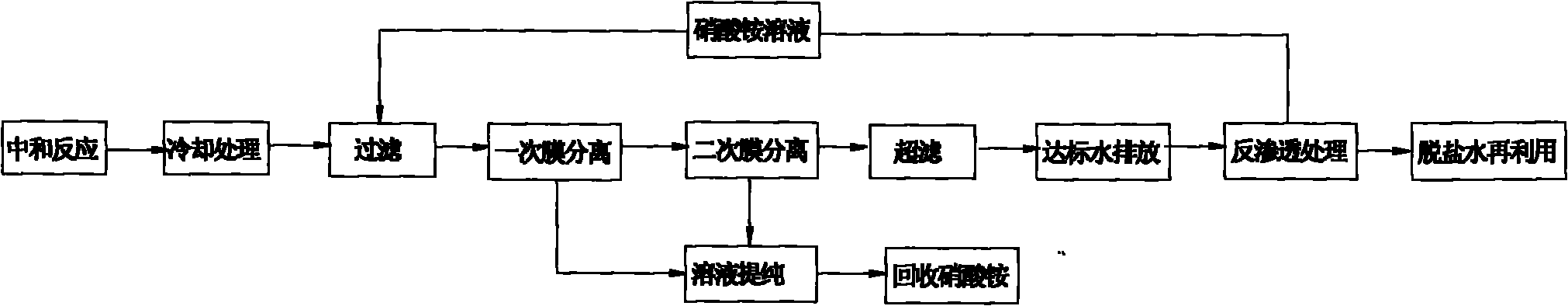

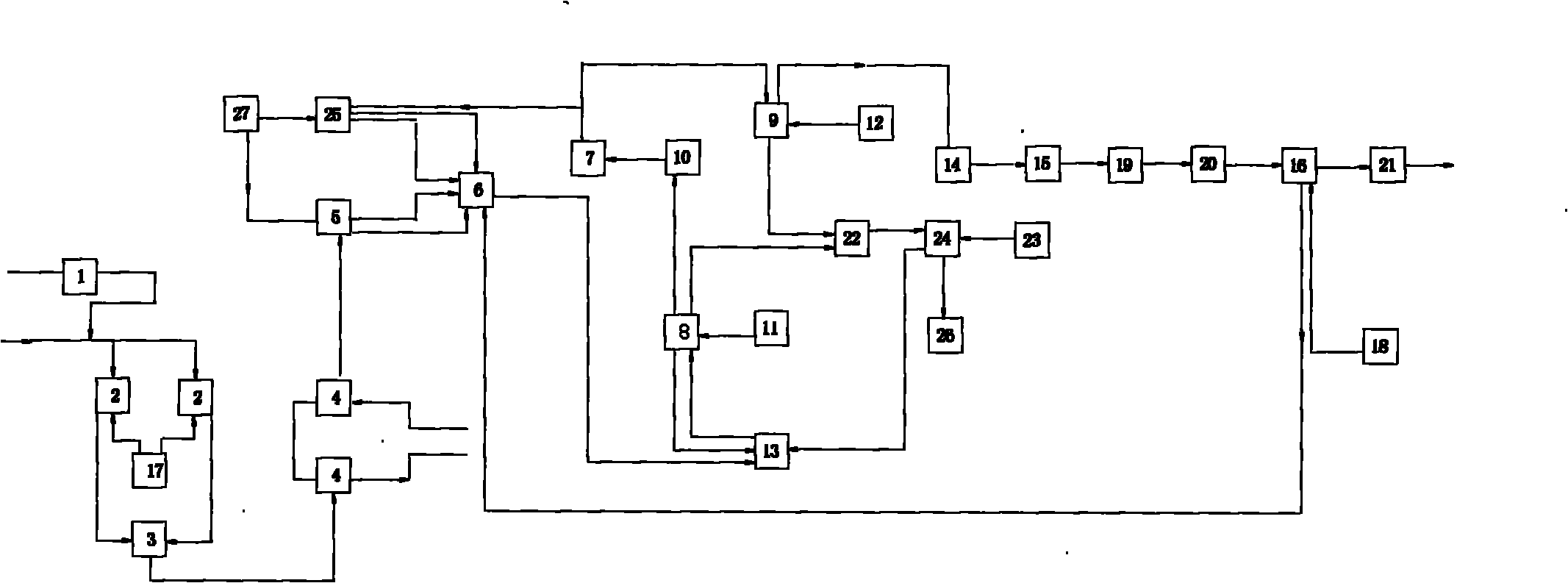

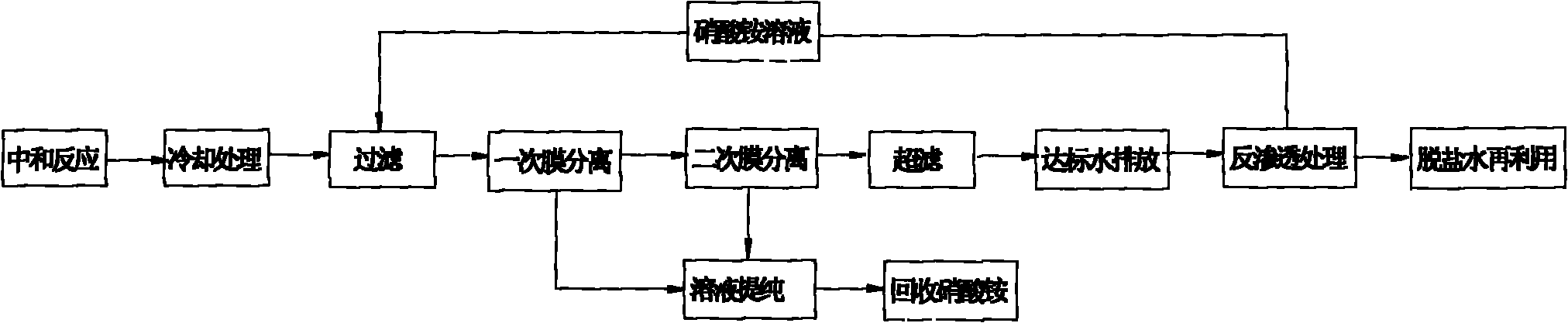

[0019] An ammonium nitrate production enterprise with an annual output of 200,000 tons of ammonium nitrate and condensed waste water of 25 cubic meters per hour, of which the content of free ammonia is 700 mg / liter and the content of ammonium nitrate is 900 mg / liter. figure 1 A process flow diagram of the invention is shown. figure 2 It is a schematic diagram of the specific process flow of an embodiment of the present invention, wherein: metering detection and adjustment device 1, neutralization reaction tank 2, collection tank 3, cooler 4, precision filter 5, condensed water storage tank 6, secondary concentration circulation tank 7. Membrane treatment device 8, membrane treatment device 9, secondary feed tank 10, pole water tank 11, pole water tank 12, primary concentration circulation tank 13, standard water storage tank 14, high pressure pump 15, reverse osmosis system 16 , conversion device 17, backwashing device 18, flow regulation control 19, pressure regulation contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com