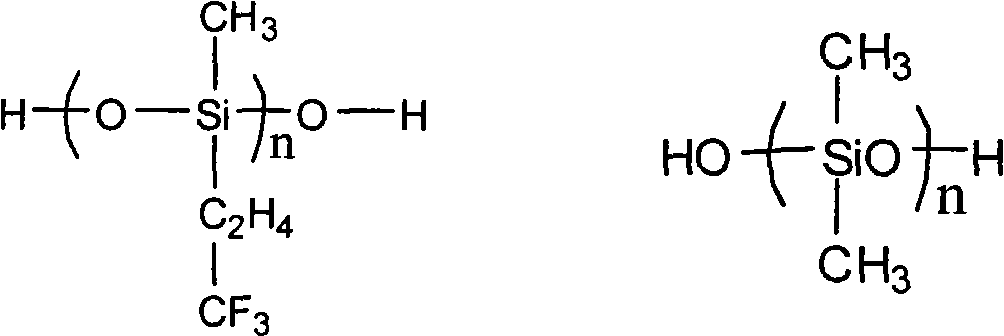

Fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and preparation method thereof

An anti-pollution flashover coating, fluorosilicone rubber technology, applied in the direction of coating, can solve the problems of low flame retardant level, difficult to reach FV-0 level, unable to meet the requirements of hydrophobicity, etc., to improve mechanical properties. , excellent hydrophobicity and anti-pollution flashover ability, the effect of anti-pollution flashover voltage increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Nanoscale fumed silica (specific surface area 200m 2 / g), aluminum hydroxide, decabromodiphenyl ether, and iron red pigment were dried at 100°C for 24 hours; fluorosilicone rubber (viscosity 5500mPa s) 10, silicone rubber (viscosity 4500mPa s) 30, nanoscale gas phase Add white carbon black 6 to the CH tank mixer, take it out after stirring for 60 minutes; put it into a vacuum stirring reactor, and vacuumize it for 3 hours while stirring, the vacuum degree is -0.08MPa; take out the slurry and put it into a high shear disperser Add the solvent haloalkane 45 and disperse at a low speed for 20 minutes; aluminum hydroxide 4, decabromodiphenyl ether 1, antioxidant tert-butylhydroquinone 0.06, leveling agent 3, pigment iron red 0.3 slowly add to the stirring slurry , stirring for 3 hours; grinding for 2 hours; under the protection of nitrogen, add defoamer 0.2, catalyst dibutyltin dilaurate 0.04, and stir for 1 hour; take out the slurry and put it into an explosion-proof high-...

Embodiment 2

[0034] Nanoscale fumed silica (specific surface area 200m 2 / g), aluminum hydroxide, decabromodiphenyl ether, and iron red pigment were dried at 100°C for 24 hours; fluorosilicone rubber (viscosity 5500mPa s) 10, silicone rubber (viscosity 4500mPa s) 25, nanoscale gas phase Add white carbon black 6 to the CH tank mixer, take it out after stirring for 60 minutes; put it into a vacuum stirring reactor, and vacuumize it for 3 hours while stirring, the vacuum degree is -0.08MPa; take out the slurry and put it into a high shear disperser Add the solvent haloalkane 50 and disperse at a low speed for 20 minutes; aluminum hydroxide 4, decabromodiphenyl ether 1, antioxidant tert-butylhydroquinone 0.06, leveling agent 3, pigment iron red 0.3 slowly add to the stirring slurry , stirring for 3 hours; grinding for 2 hours; under the protection of nitrogen, add defoamer 0.2, catalyst dibutyltin dilaurate 0.04, and stir for 1 hour; take out the slurry and put it into an explosion-proof high-...

Embodiment 3

[0036] Nanoscale fumed silica (specific surface area 200m 2 / g), aluminum hydroxide, decabromodiphenyl ether, and iron red pigment were dried at 100°C for 24 hours; fluorosilicone rubber (viscosity 5500mPa s) 5, silicone rubber (viscosity 4500mPa s) 25, nanoscale gas phase Add white carbon black 8 to the CH tank mixer, take it out after stirring for 60 minutes; put it into the vacuum stirring reactor, and vacuumize it for 3 hours while stirring, the vacuum degree is -0.08MPa; take out the slurry, put it into the high shear dispersion In the machine, add solvent haloalkane 55 and stir at low speed for 20 minutes; aluminum hydroxide 3, decabromodiphenyl ether 1, antioxidant tert-butyl hydroquinone 0.06, leveling agent 2, pigment iron red 0.3 slowly add to the stirring Slurry, stirring time 3 hours; grinding 2 hours; under the protection of nitrogen, add defoamer 0.2, catalyst dibutyltin dilaurate 0.04, stir for 1 hour; take out the slurry and put it into an explosion-proof high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com