Treatment method and device of landfill leachate concentrate

A landfill leachate and treatment device technology, which is applied in the landfill leachate and other high-concentration organic wastewater industries, the treatment of landfill leachate concentrate, and the field of landfill leachate treatment in incineration power plants, can solve the problem of high salinity in biochemical treatment, High operating costs, easy corrosion of equipment, etc., to achieve the effect of recycling, saving operating costs, and avoiding membrane surface pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

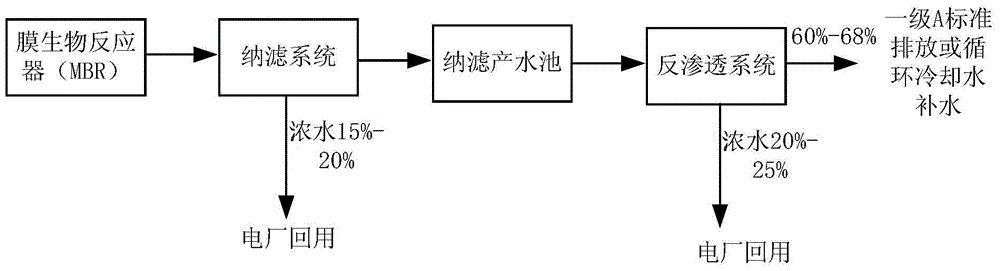

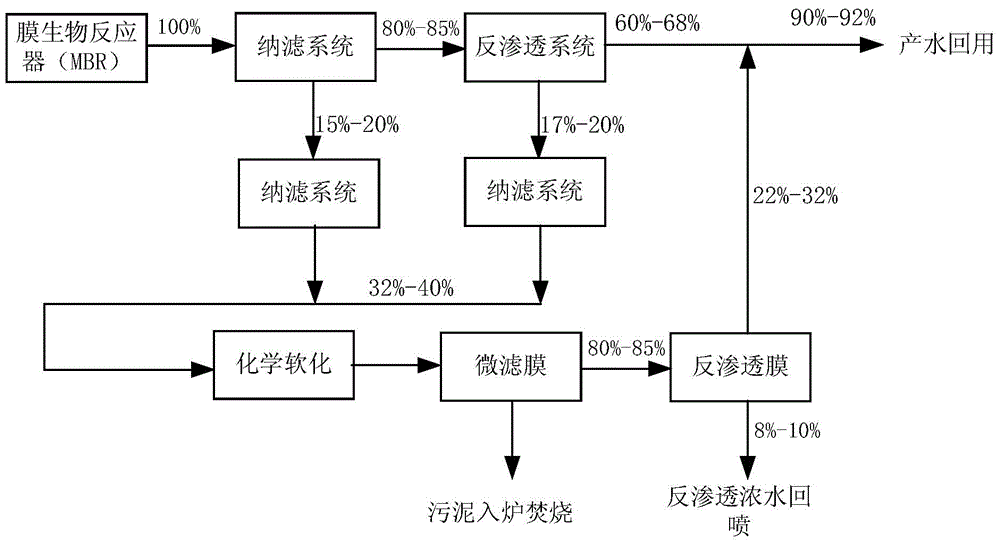

[0047] In order to solve the problems existing in the prior art, the present invention provides a method for treating the landfill leachate concentrate, wherein the landfill leachate concentrate is a conventional method to perform nanofiltration and / or reverse osmosis on the landfill leachate Concentrated water obtained after treatment, among them, the treatment method of landfill leachate is as follows figure 1 As shown, the process flow is that MBR effluent directly receives filtration and reverse osmosis process, the yield of nanofiltration concentrate is about 15% to 20% of the influent water, and the yield of reverse osmosis concentrate is about 20% to 20% of the reverse osmosis influent 25%, and the total concentrate production rate is about 32% to 40%. For example, the daily treatment scale of the leachate treatment station is 1000m3 / d, the concentrate output is about 320-400m 3 / d.

[0048] The "dual-membrane method" of nanofiltration + reverse osmosis, as a filtrat...

Embodiment 2

[0074] The present invention also provides a concentrate treatment device based on the above method, comprising:

[0075] The chemical softening unit is used to chemically soften the concentrated liquid to reduce the hardness of the landfill leachate concentrated liquid;

[0076] A microfiltration membrane unit is used to filter the effluent from the chemical softening unit to remove suspended solids in the concentrate;

[0077] The reverse osmosis unit includes a dish-type reverse osmosis membrane, which is used for performing reverse osmosis treatment on the effluent of the microfiltration membrane unit.

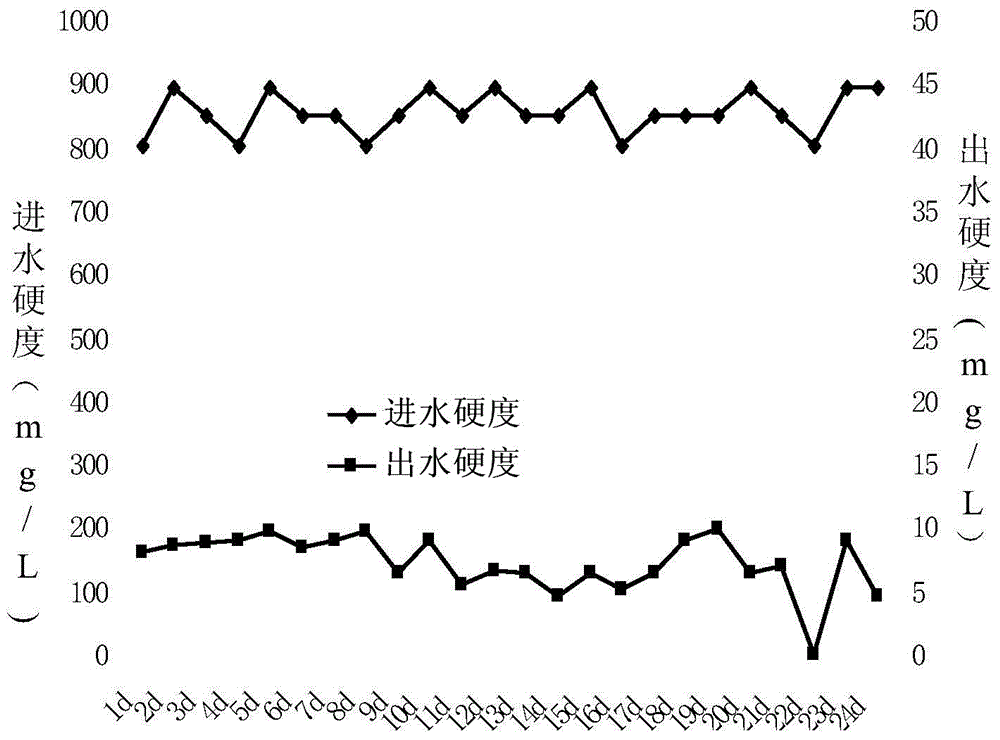

[0078] Wherein, the chemical softening unit is composed of an intermediate pool, a mixing pool, and a reaction pool. After the nanofiltration and reverse osmosis concentrates are mixed in the intermediate pool, they enter the mixing pool. The mixing pool mainly adds calcium hydroxide and calcium hydroxide The final pH is controlled at about 11-11.5, and the landfill leach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com