Automobile toughened glass ink and preparation method thereof

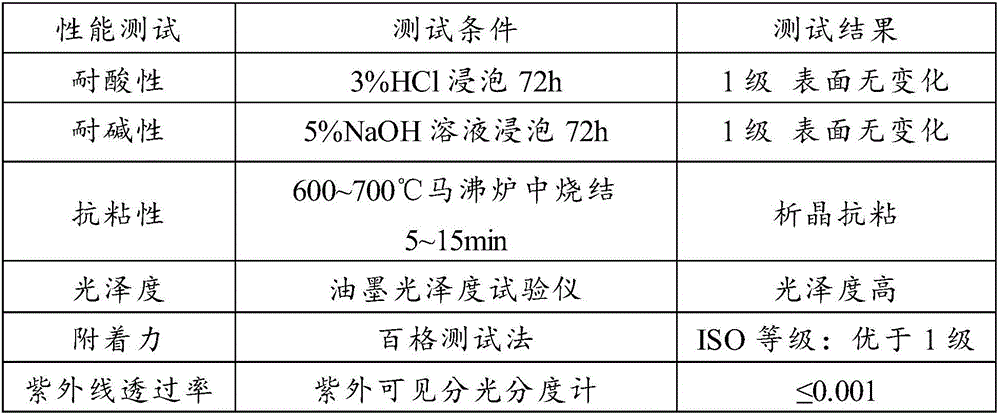

A technology of glass ink and automobile steel, which is applied in glass manufacturing equipment, ink, glass tempering, etc. It can solve the problems of graying on the surface of the glaze layer, decline in acid resistance, and affect the appearance, and achieve high adhesion and acid and alkali resistance. Strong, good anti-stick effect of non-stick mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned glass powder is specifically:

[0028] 74wt% ~ 85wt% Bi 2 o 3 , 2wt% ~ 11wt% SiO 2 , 2wt% ~ 11wt% of B 2 o 3 , 2wt% ~ 5wt% Al 2 o 3 It is mixed with 2wt%-5wt% ZnO, then kept at 1100-1300°C for 0.5-2h, water quenched and ground to obtain glass powder.

[0029] The particle size of the glass powder described in the present application is less than 2 μm; in a specific embodiment, in the glass powder, Bi 2 o 3 The content of SiO is 78-83wt%, and the SiO 2 The content of B is 3~10wt%, said B 2 o 3 The content of Al is 3-8wt%, and the Al 2 o 3 The content of ZnO is 2-4wt%, and the content of ZnO is 3-5wt%.

[0030] In the present application, the automotive tempered glass ink also includes inorganic pigments, varnishes, dispersants, leveling agents and thixotropic agents, wherein the inorganic pigments are composed of copper chrome black and cobalt black; the varnish is composed of high Composed of molecular resin an...

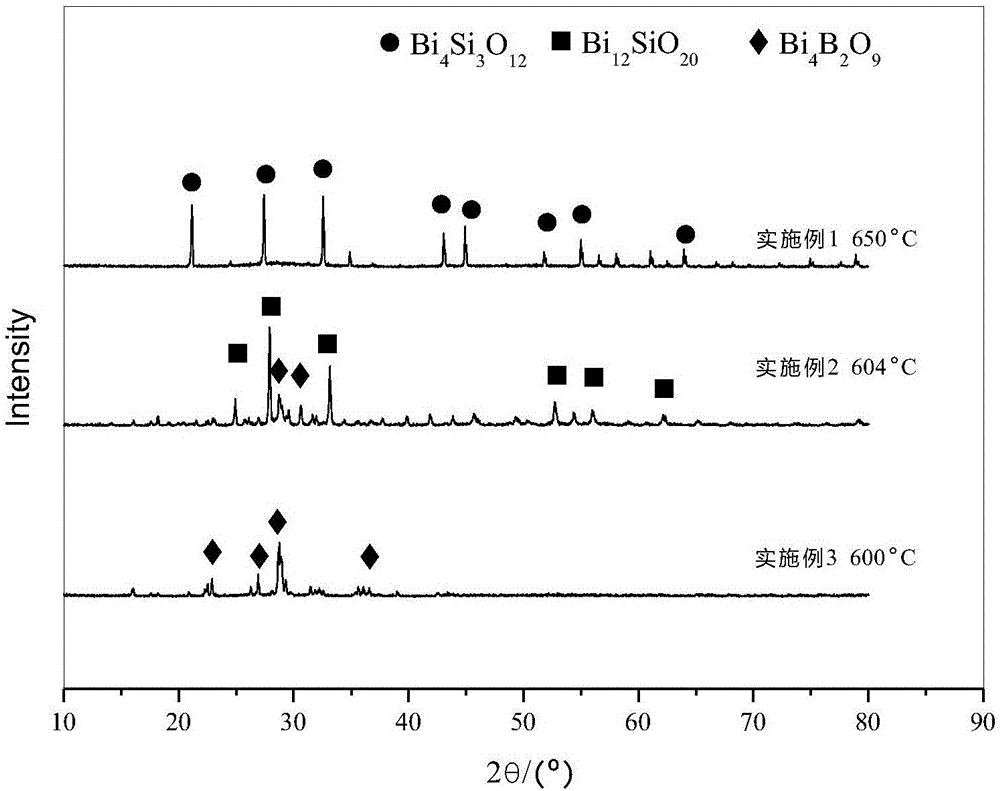

Embodiment 1

[0043] A kind of automotive tempered glass ink containing easily devitrified bismuth-based glass powder, composed of bismuth-based glass powder, inorganic pigment, varnish, dispersant, leveling agent and thixotropic agent, the mass percentage of each raw material is : Bismuth glass powder 55%, inorganic pigment 20%, varnish 23.8%, dispersant 0.5%, leveling agent 0.5%, thixotropic agent 0.2%; inorganic pigment is copper chrome black with a mass ratio of 1:9 The mixture with cobalt black, the varnish is uniformly mixed with polyvinyl butyral, diethylene glycol and terpineol in a volume ratio of 2:3:5, the dispersant is the amine salt solution of polycarboxylic acid, and the leveling agent It is polyacrylate, and the thixotropic agent is fumed silica.

[0044] The preparation method of the automobile toughened glass ink of this embodiment comprises two steps:

[0045] 1) Preparation of bismuth-based glass powder

[0046] 82% Bi by weight percentage of raw materials 2 o 3 , 9%...

Embodiment 2

[0051] An automotive tempered glass ink containing easily devitrified bismuth-based glass powder, which is composed of bismuth-based glass powder, inorganic pigments, varnish, dispersant, leveling agent and thixotropic agent, and the mass percentage of each raw material It is: 60% of bismuth-based glass powder, 15% of inorganic pigment, 23.8% of varnish, 0.5% of dispersant, 0.5% of leveling agent, and 0.2% of thixotropic agent; the inorganic pigment is copper chromium with a mass ratio of 1:9 A mixture of black and cobalt black. The varnish is uniformly mixed with polyvinyl butyral, diethylene glycol and terpineol at a volume ratio of 2:3:5. The dispersant is the amine salt solution of polycarboxylic acid. Leveling The agent is polyacrylate, and the thixotropic agent is fumed silica.

[0052] The preparation method of the automobile toughened glass ink of this embodiment comprises two steps:

[0053] 1) Preparation of bismuth-based glass powder

[0054] 81% Bi by weight perc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com