Emulsion ultrasonic emulsion breaking device

A demulsification device and technology for emulsification, which are applied in the field of devices for demulsification and separation of oil-water emulsions, can solve the problems of slowing the movement speed of the emulsion, reducing the efficiency and effect of ultrasonic demulsification, and failing to achieve the demulsification effect. Improve efficiency and effectiveness, and expand the effect of the area of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

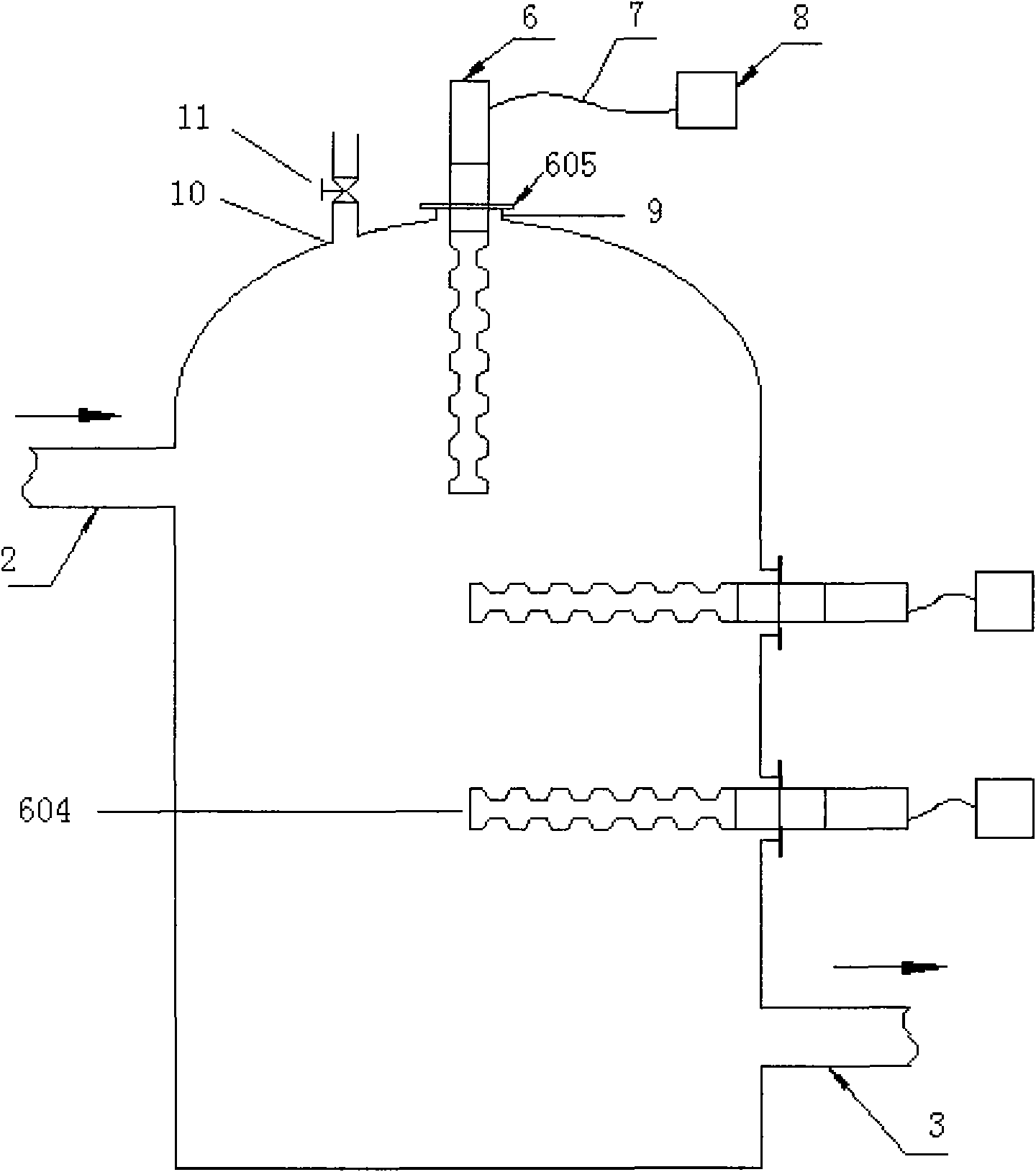

[0025] Such as figure 1 As shown, an emulsion ultrasonic demulsification device adopted in the present embodiment includes a vertical or tower chamber 1, an exhaust port 10 and its corresponding exhaust valve 11 are arranged on the top of the chamber 1, The input port 2 of the emulsion is located at the upper part of the vertical cavity, and the output port 3 of the emulsion is arranged at the lower part of the cavity, and the liquid in the cavity is used to act on the liquid in the cavity or a columnar ultrasonic vibration system, according to the shape of the cavity 1 and Volume, at least one set of ultrasonic vibration system 6 is evenly distributed on the top and side of the cavity in turn, so that the emulsion in the cavity can obtain the largest uniform action area. During the slow movement from top to bottom, the emulsion in the cavity is irradiated by omni-directional ultrasonic waves emitted by at least one ultrasonic device, and the action time is prolonged. The ele...

Embodiment 2

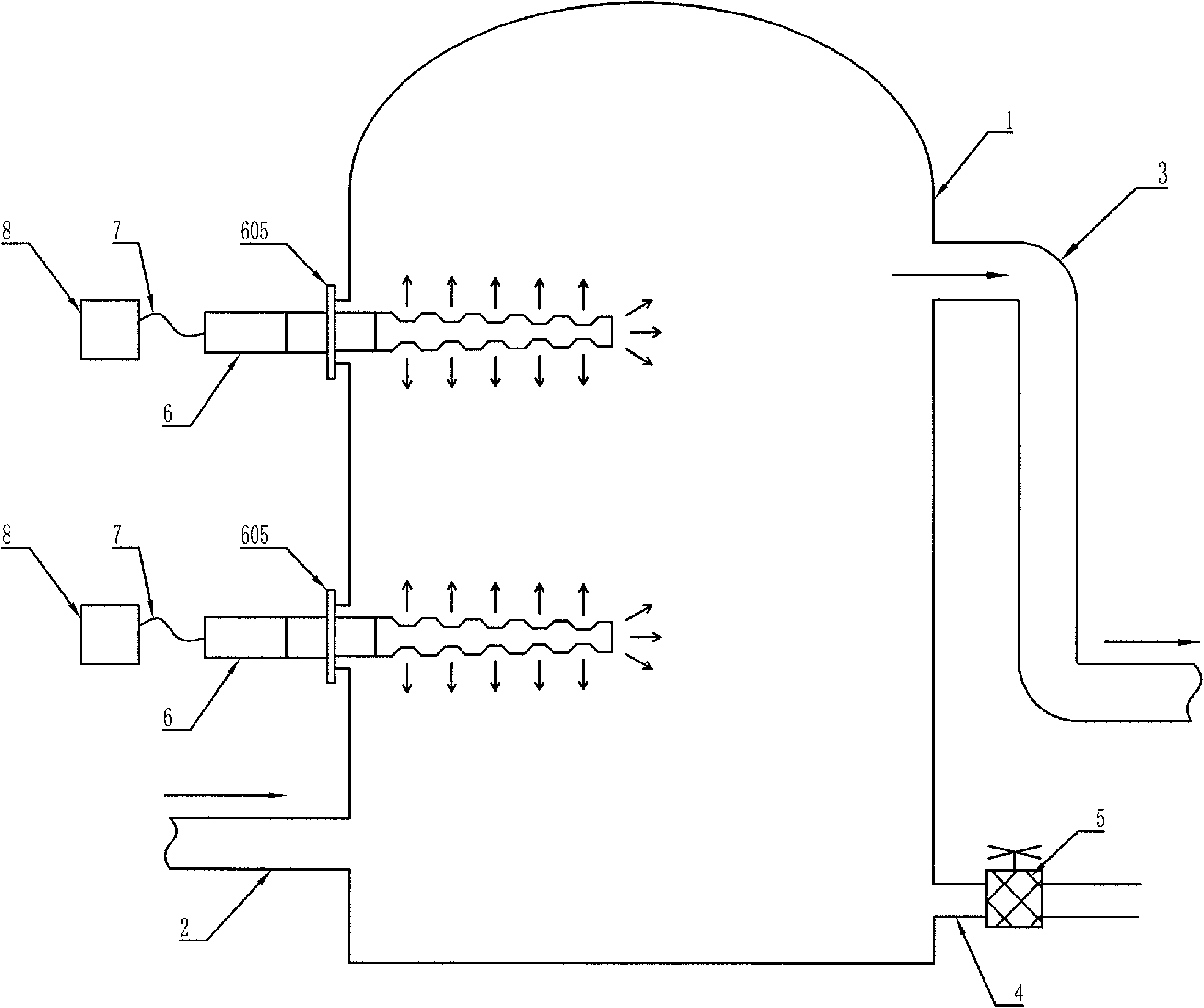

[0028] Such as figure 2As shown, an ultrasonic demulsification device adopted in this embodiment includes a vertical or tower chamber 1, the input port 2 of the emulsion is arranged near the lower part of the chamber, and the output port 3 of the emulsion is arranged In the upper part of the cavity 1, in order to avoid the accumulation of detached water at the bottom of the cavity after working for a long time, there is also a drain pipe 4 and a corresponding control valve 5 at the bottom of the cavity for The part of the effusion with a relatively large specific gravity in the emulsion is discharged, and at least one set of ultrasonic vibration system is installed on the wall of the cavity through the flange 9. The transverse maximum dimension (diagonal) of the transducer part 601 of the ultrasonic vibration system is 57mm, the cross-sectional diameter of the protruding part in the middle of the rod body of the tool head 603 and the diameter of the front end surface 604 are ...

Embodiment 3

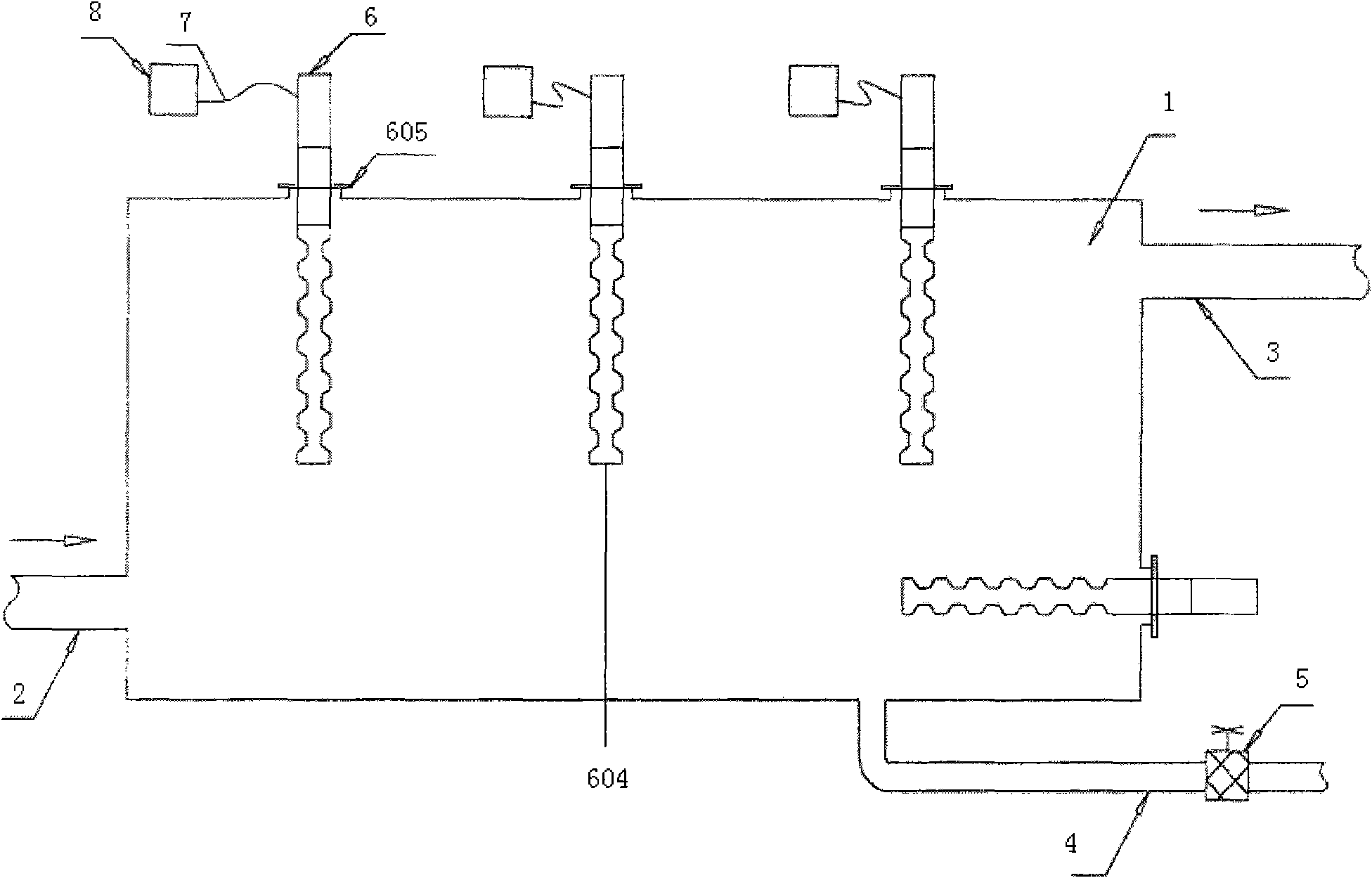

[0030] Such as image 3 As shown, an ultrasonic demulsification device used in this embodiment includes a horizontal cavity 1, the diameter of which is much larger than that of the input and output pipelines, generally greater than twice. The input port 2 of the emulsion is set near the lower part of the cavity, and the output port 3 of the emulsion is set at the upper part of the cavity. The emulsion entering the cavity is emitted by the ultrasonic generator installed on the side of the cavity during the slow flow process. In order to avoid the accumulation of prolapsed water at the bottom of the cavity after long-term work, a drain pipe 4 and a corresponding control valve 5 are also provided at the bottom of the cavity to drain the The part of the effusion with a relatively large specific gravity in the emulsion is discharged, and at least one set of ultrasonic vibration system is installed on the wall of the cavity through the flange 9, and the transverse maximum dimension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com