Super-hydrophilic polymer microporous membrane, and preparation method and application thereof

A polymer and super-hydrophilic technology, which is applied in the field of polymer microporous membranes and superhydrophilic polymer microporous membranes, can solve the problems of limited wide application and strong toxicity of polyethyleneimine, and achieves simple process and low price. , The effect of high oil-water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a super-hydrophilic polymer microporous membrane provided by an aspect of the embodiments of the present invention includes: immersing the pretreated polymer microfiltration membrane in the immersion liquid for 4 to 6 minutes, and then pouring into the immersion liquid Dissolve dopamine hydrochloride and tannic acid in the water, and shake at 25-45°C for 4-24 hours, then take the polymer microfiltration membrane out of the immersion solution, wash and dry it, and obtain super-hydrophilic polymer microporous membrane.

[0021] In some embodiments, the pretreatment includes: soaking the polymer microfiltration membrane in absolute ethanol.

[0022] In some embodiments, the polymer microfiltration membrane includes polypropylene microfiltration membrane, polyvinylidene fluoride microfiltration membrane, polytetrafluoroethylene membrane, polysulfone microfiltration membrane, nylon microfiltration membrane, cellulose acetate microfiltration membrane A...

Embodiment 1

[0040] Embodiment 1 A kind of preparation method of superhydrophilic polypropylene microporous membrane comprises the following steps:

[0041] (1) Soak the polypropylene microfiltration membrane with a pore size of 0.2 microns in absolute ethanol, then place it in 100 mL of Tris-HCl soaking solution for 5 minutes, and the pH of the Tris-HCl solution is 8.5;

[0042] (2) Dissolving 0.1 g of dopamine hydrochloride and 0.1 g of tannic acid in the impregnation solution containing the polymer microfiltration membrane, and shaking at 45° C. for 8 hours;

[0043] (3) The polypropylene microfiltration membrane is taken out from the soaking solution, washed with clear water and dried in the air to obtain a superhydrophilic polymer microporous membrane.

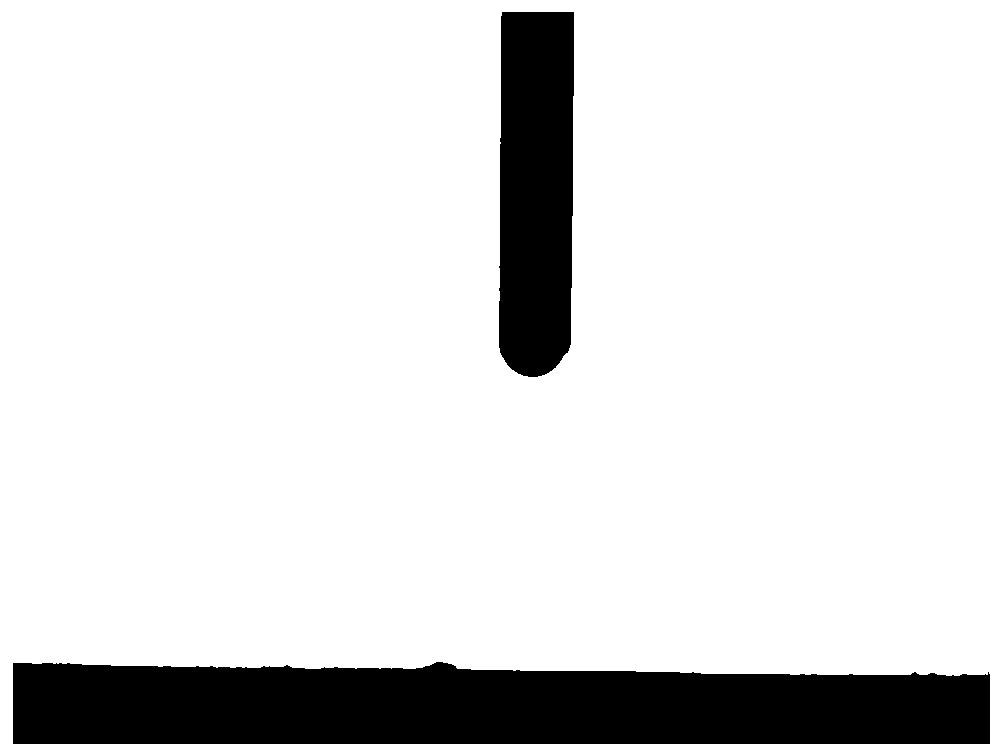

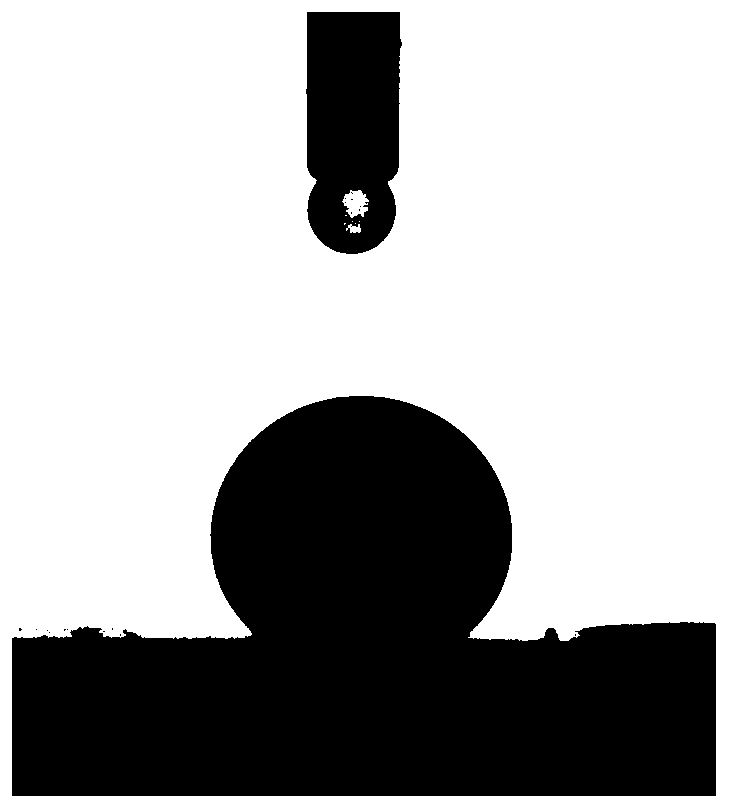

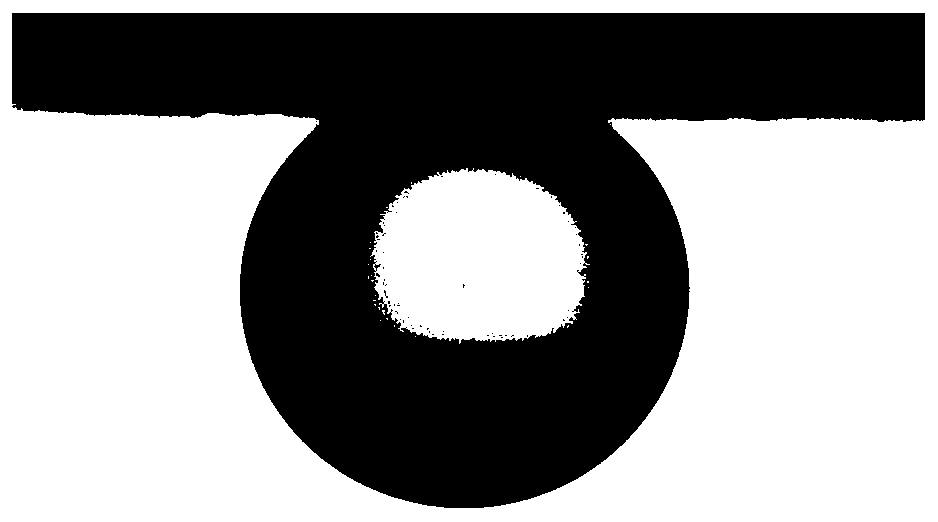

[0044] The water contact angle of the modified polypropylene film obtained in this embodiment becomes 0° in 1 second (see figure 1 ), it was placed under water to measure the contact angle of this film with 1 microliter of methylene ...

Embodiment 2

[0047] Embodiment 2 A kind of preparation method of superhydrophilic polyvinylidene fluoride microporous membrane comprises the following steps:

[0048] (1) Soak a polyvinylidene fluoride microfiltration membrane with a pore size of 0.2 microns in absolute ethanol, and then soak it in 100 mL of Tris-HCl soaking solution for 5 minutes, and the pH of the Tris-HCl solution is 9.5;

[0049] (2) Dissolving 0.05g of dopamine hydrochloride and 0.15g of tannic acid in the impregnation solution containing the polymer microfiltration membrane, and shaking at 40°C for 4 hours;

[0050](3) Take out the polyvinylidene fluoride microfiltration membrane from the immersion solution, wash it with clear water and dry it in the air to obtain a superhydrophilic polymer microporous membrane.

[0051] The water contact angle of the modified polyvinylidene fluoride film obtained in this embodiment becomes 0° in 1 second, and it is placed under water to measure the contact angle of the film with 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com