System and method for separating a trace element from a liquid hydrocarbon feed

a trace element and liquid hydrocarbon technology, applied in the direction of separation processes, refining by water treatment, transportation and packaging, etc., can solve the problems of corroding equipment, deteriorating or poisoning catalysts, and the removal of deleterious metals from equipment that can be very expensive and potentially hazardous, so as to achieve the effect of easy separation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Hydrocarbon feeds, generally a conglomeration of hydrocarbon chains with approximate lengths ranging between C5H12 and C42H86, typically contain a variety of trace elements. The trace elements range from alkaline earth metals, transition metals, post-transition metals, and nonmetals and generally consist of calcium (Ca), vanadium (V), chromium (Cr), iron (Fe), cobalt (Co), nickel (Ni), copper (Cu), zinc (Zn), arsenic (As), selenium (Se), molybdenum (Mo), cadmium (Cd), indium (In), tin (Sn), antimony (Sb), tellurium (Te), barium (Ba), mercury (Hg), thallium (Tl), lead (Pb), and / or bismuth (Bi). For various reasons, including corrosion prevention and ensuring environmental sustainability, it is often desirable to extract one or more of these trace elements during initial treatment of the feed.

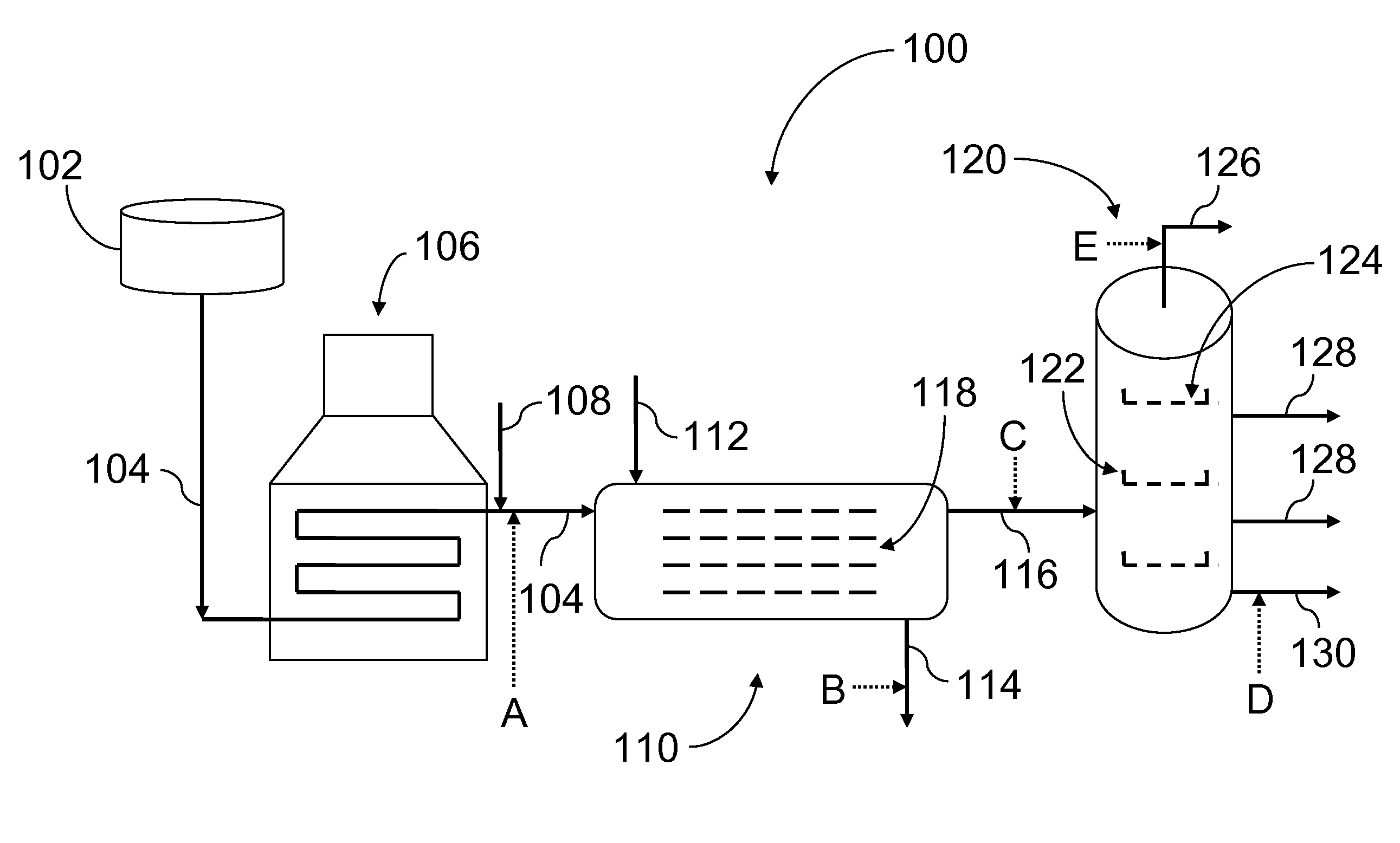

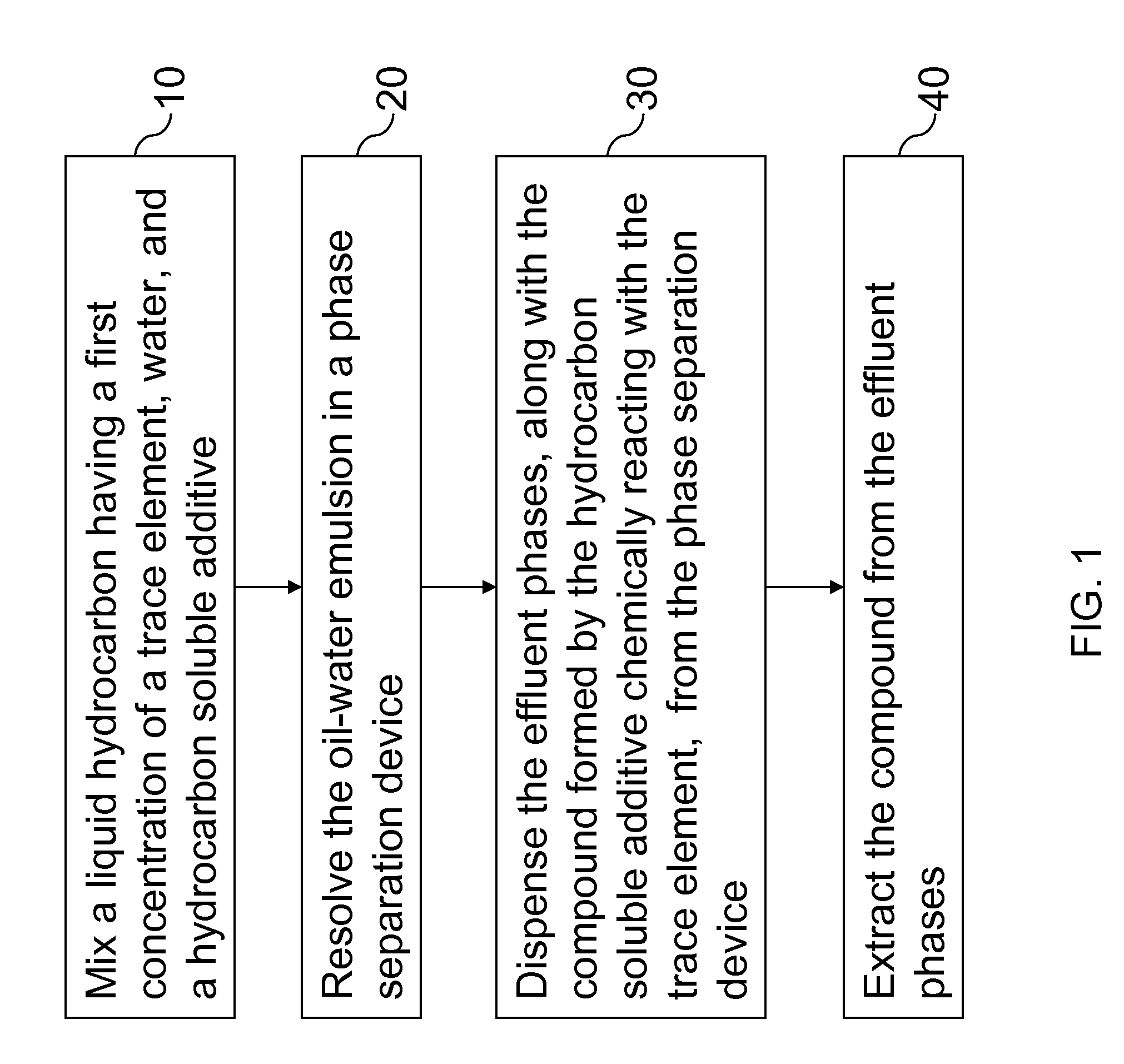

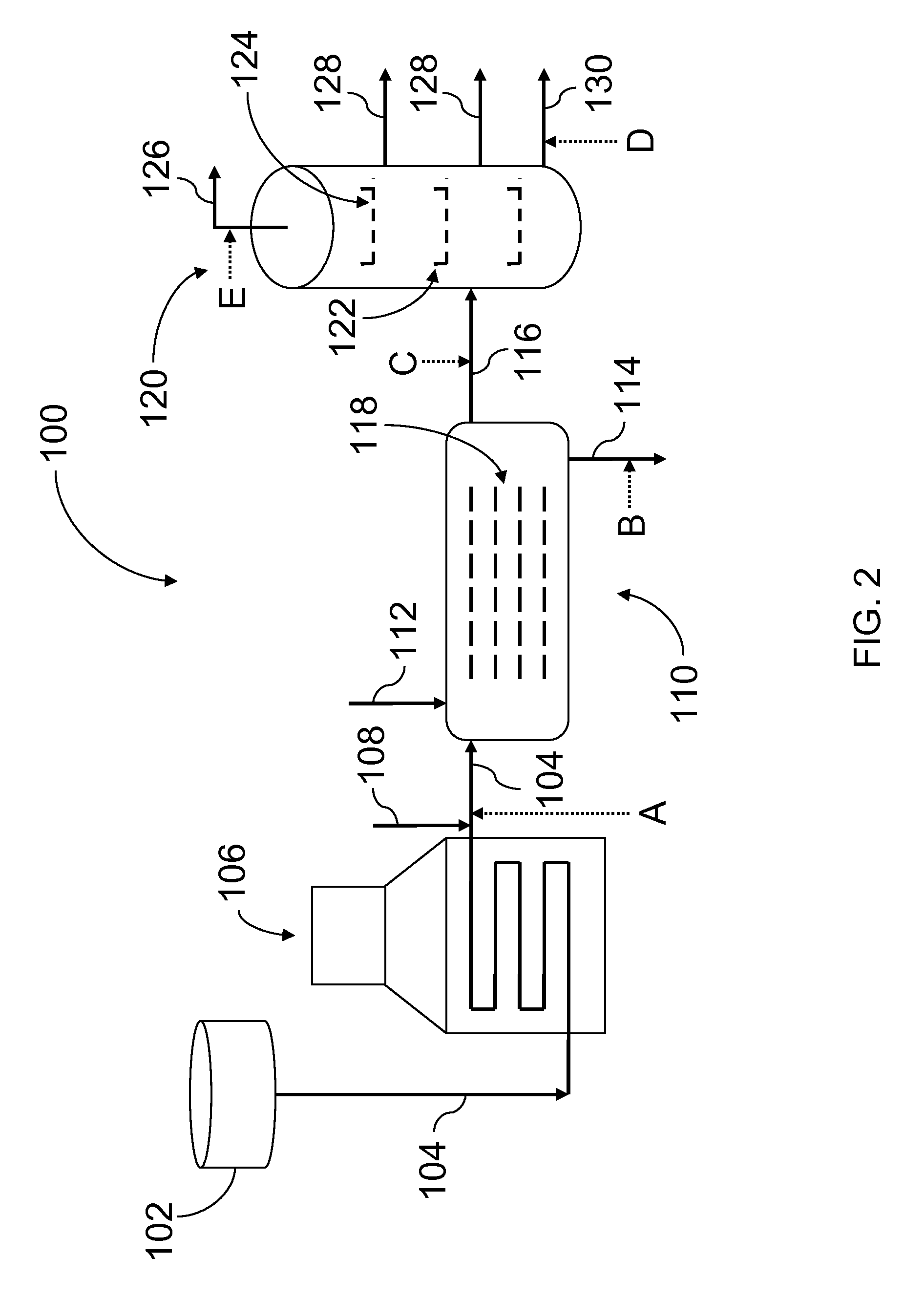

[0016]FIG. 1 depicts steps, according to one method of the present invention, for removal of a trace element from a liquid hydrocarbon. First, as shown in step 10, a hydrocarbon-soluble add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility (mass) | aaaaa | aaaaa |

| Electric field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com