Net film applied to oil-in-water emulsion separation, preparation method and application of net film

An emulsion separation and omentum membrane technology, applied in separation methods, liquid separation, filtration separation, etc., can solve the problems that the omentum membrane can only separate a certain kind of emulsion, the conditions are difficult to control, and the production process is complicated, and it is easy to clean and separate. Fast, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

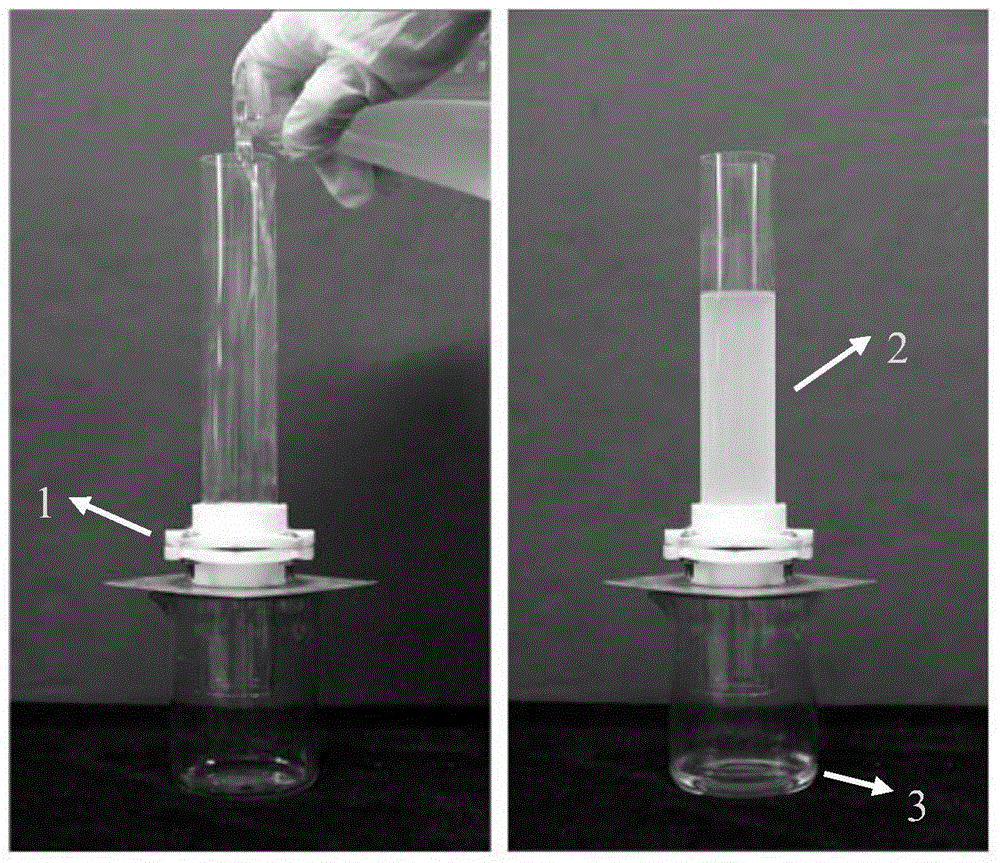

[0048] Embodiment 1, preparation is used for the omentum of oil-water emulsion separation and its oil-water emulsion separation effect

[0049] 1) Preparation of omentum for oil-water emulsion separation

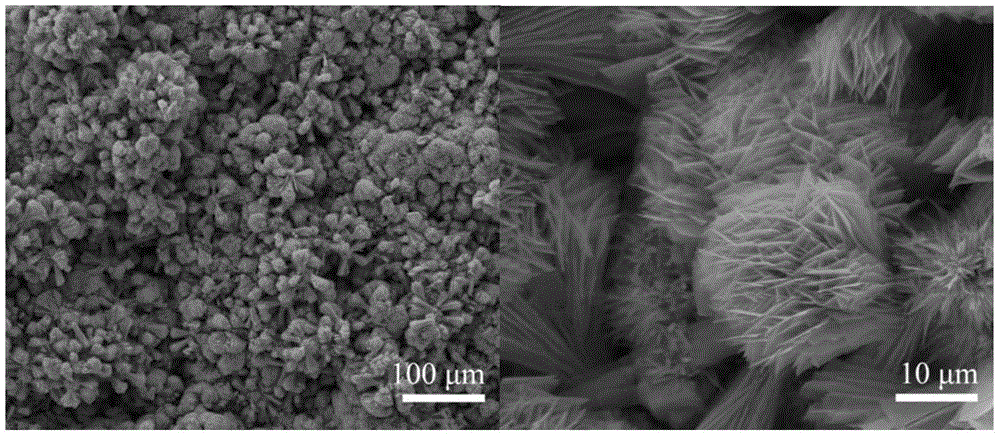

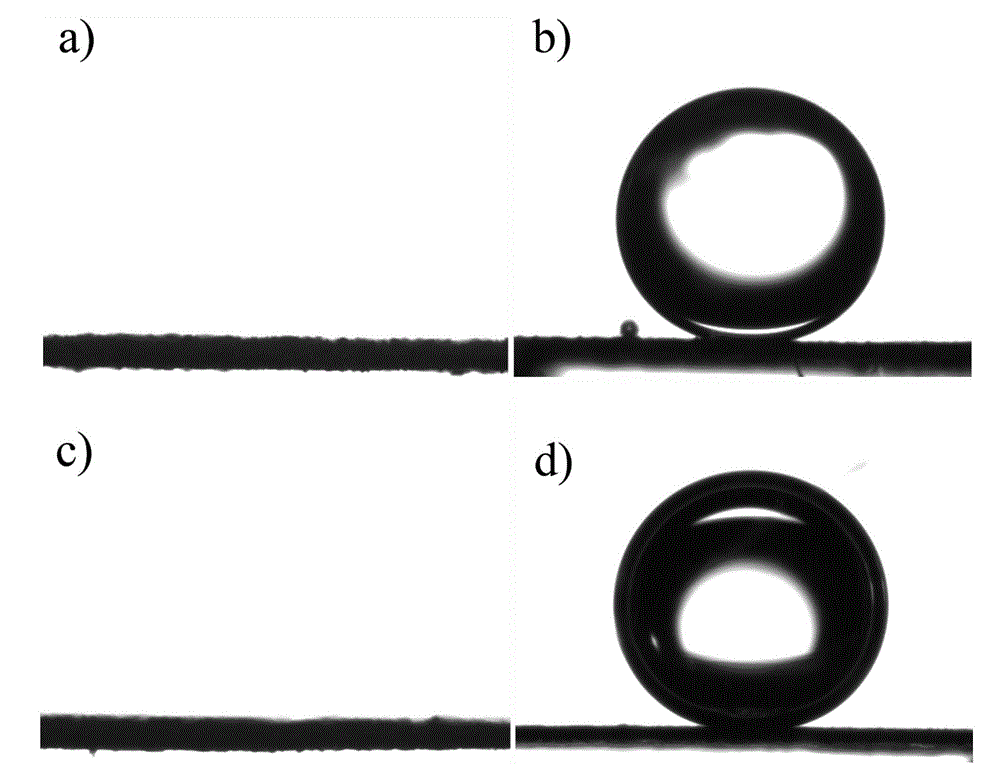

[0050] (1) The 300-mesh copper mesh is immersed in ethanol and acetone in turn, each ultrasonically cleaned for 15 minutes, soaked in hydrochloric acid for 1 hour (to remove possible impurities on the metal mesh to facilitate subsequent reactions), and deposit copper particles by electrochemical deposition (Specifically: place the above-mentioned copper mesh in 0.5mol / L copper sulfate solution, use an electrochemical workstation to perform electrodeposition treatment, the reaction voltage is 1.5V, and the reaction time is 1min), increase its roughness, and dry at room temperature;

[0051] (2) At room temperature, add 6.38g zinc acetate, 0.14g sodium hydroxide and 100ml water in a 250ml beaker, stir well to obtain a mixed solution, in this mixed solution, the molar concentra...

Embodiment 2

[0059] Embodiment 2, preparation is used for the omentum of oil-water emulsion separation and its oil-water emulsion separation effect

[0060] 1) Preparation of omentum for oil-water emulsion separation

[0061] (1) The 400-mesh copper grid is immersed in ethanol and acetone in turn, ultrasonically cleaned for 15 minutes each, soaked in hydrochloric acid for 1 hour, and dried at room temperature;

[0062] (2) At room temperature, add 5.80g zinc acetate, 0.168g potassium hydroxide and 100ml water in a 250ml beaker, stir well to obtain a mixed solution, in this mixed solution, the molar concentration of zinc acetate is 0.50mol / L, potassium hydroxide The molar concentration is 0.030mol / L;

[0063] (3) The mixed solution obtained in step (2) is transferred to the hydrothermal reaction kettle, and the copper mesh obtained in the step (1) is also placed in the reaction kettle, so that it is completely immersed in the mixed solution, at 80 The hydrothermal reaction was carried out...

Embodiment 3

[0070] Embodiment 3 preparation is used for the omentum of oil-water emulsion separation and its oil-water emulsion separation effect

[0071] 1) Preparation of omentum for oil-water emulsion separation

[0072] (1) 400-mesh stainless steel is immersed in ethanol and acetone in turn, ultrasonically cleaned for 15 minutes each, soaked in hydrochloric acid for 1 hour, and dried at room temperature;

[0073] (2) At room temperature, add 6.96g of zinc acetate, 0.084g of potassium hydroxide and 100ml of water into a 250ml beaker, and stir evenly to obtain a mixed solution. In this mixed solution, the molar concentration of zinc acetate is 0.60mol / L, lithium hydroxide The molar concentration is 0.035mol / L;

[0074] (3) The mixed solution obtained in step (2) is transferred to the hydrothermal reaction kettle, and the stainless steel mesh obtained in the step (1) is also placed in the reaction kettle, so that it is completely immersed in the mixed solution, at 90 The hydrothermal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com