Multilayer phospholipid protein microcapsule for drug slow release wall material and its preparation method

A technology of protein and microcapsules, which is applied in the direction of microcapsules, capsule delivery, non-effective ingredients of polymer compounds, etc., can solve the problems of fragmentation, incomplete microcapsules, and changes in the physical and chemical properties of wall materials, and achieve easy control and preparation The effect of simple device and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

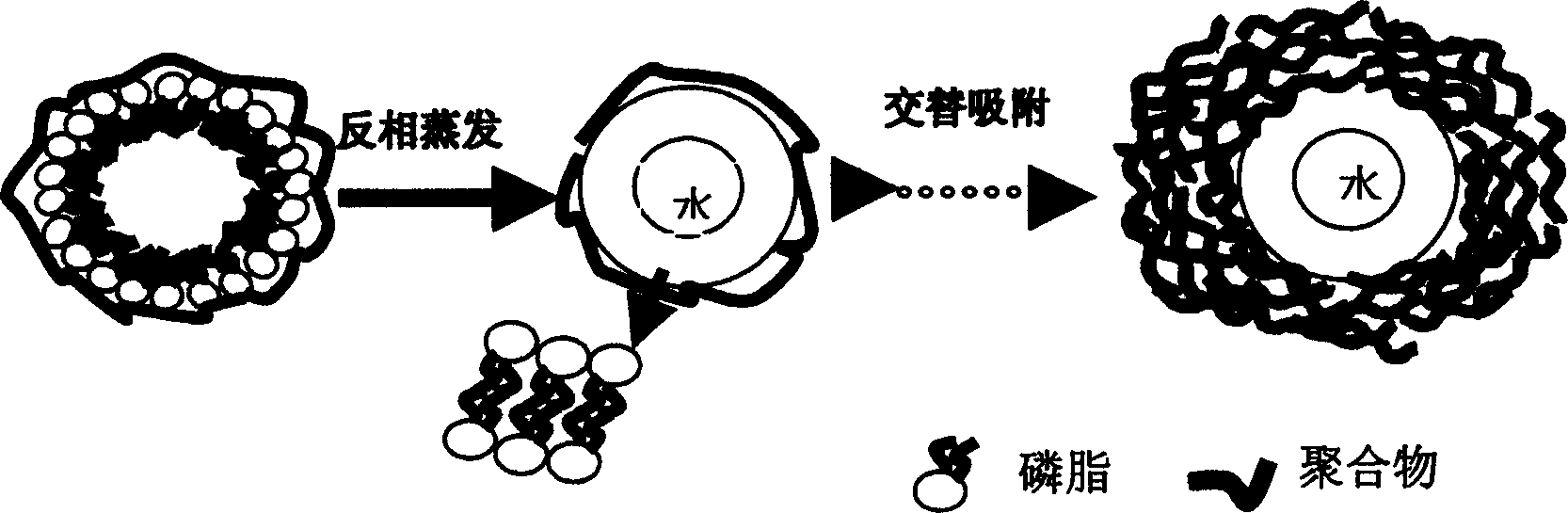

[0028] The preparation method of the multilayered phospholipid / protein microcapsule used as drug slow-release wall material is to dissolve the fat-soluble phospholipid in an organic solvent, and then disperse it in an aqueous solution containing protein. The specific steps are as follows:

[0029] 1) Use an organic solvent to dissolve fat-soluble phospholipids into an emulsion; dissolve the protein in water to form an aqueous solution,

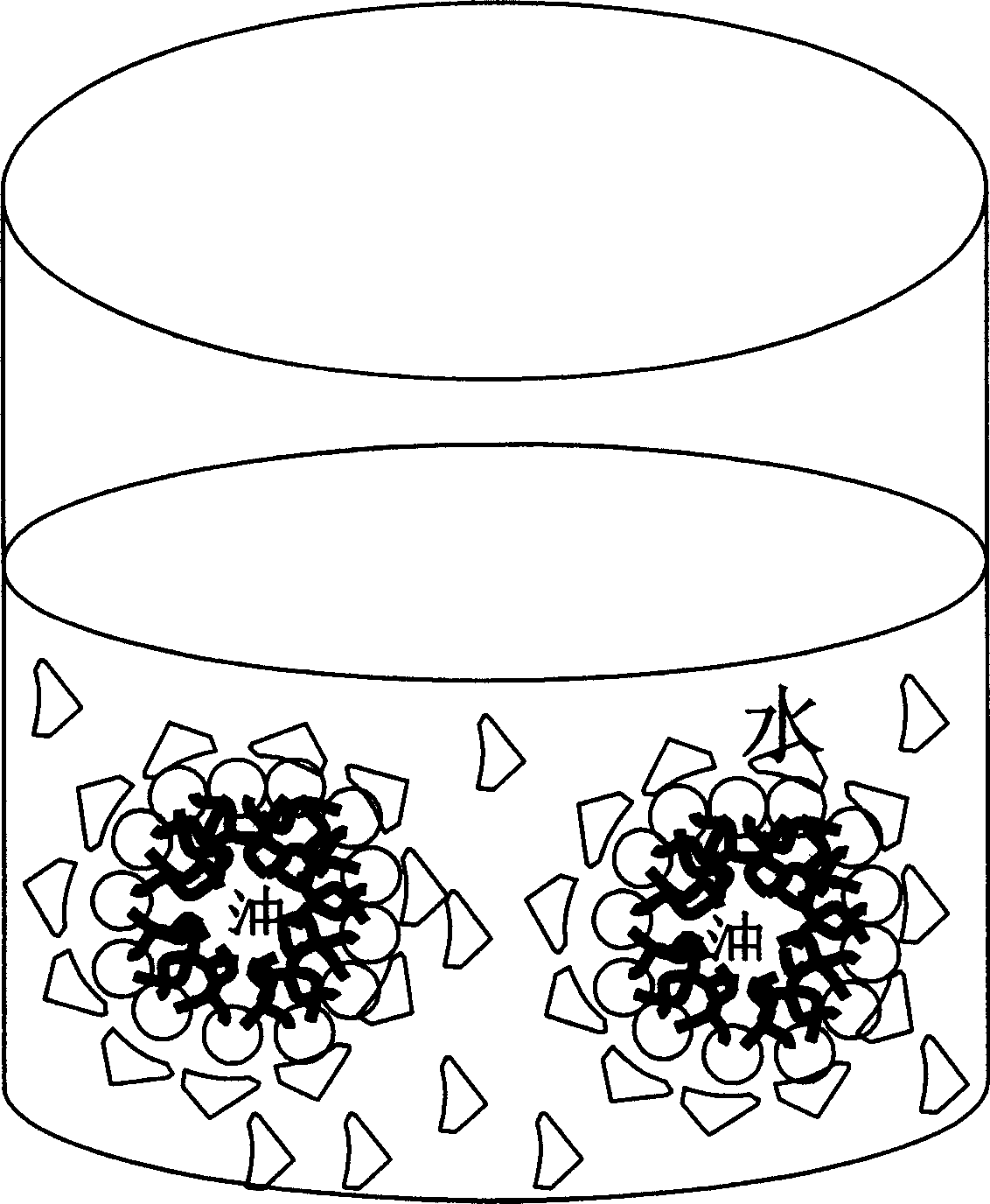

[0030] 2) Using a syringe pump to form the above emulsion into spherical droplets, then inject the chloroform spherical droplets containing fat-soluble phospholipids into the aqueous solution containing protein to generate a mixed solution,

[0031] 3) Rotate the above mixed solution on a rotary evaporator to volatilize the organic solvent,

[0032] 4) After the organic solvent is volatilized, the redundant polymer in the mixed solution is removed by centrifugation, and the phospholipid microcapsules with protein adsorption are obtained.

[0...

Embodiment 1

[0034] Embodiment 1: prepare the dipalmitoylphosphatidylcholine (DPPC) / bovine serum albumin multilayer polymer microcapsules with a size of about 5 microns:

[0035] Preparation of the oil phase solution: the phospholipid DPPC was dissolved in the organic solvent chloroform to form the oil phase with a concentration of 0.1 mg / ml.

[0036] Aqueous phase solution preparation: protein human serum was dissolved in tris-hydrochloric acid aqueous solution at a concentration of 0.1 mg / ml.

[0037] Use the electromagnetic pump at a speed of 1.0ml / min to make the oil droplets form droplets at the injection port, and disperse them drop by drop in the aqueous solution, then put the flask on a rotary evaporator to evaporate the chloroform completely, and rinse it with distilled water . Then, multi-layer polymer microcapsules are obtained through layer-by-layer adsorption self-assembly, with a size of about 10 microns.

Embodiment 2

[0038] Example 2: The concentration of the oil phase solution is 0.5 mg / ml, and the concentration of the water phase solution is 1.0 mg / ml. The operation steps are the same as above, and multilayer polymer microcapsules with a size of about 20 microns can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com