Method and device for performing emulsion breaking on oil-water emulsion by ultrasonic wave

An oil-water emulsion and ultrasonic technology, applied in the direction of electric/magnetic dehydration/demulsification, etc., can solve the problems of inability to exert the ultrasonic demulsification effect, short ultrasonic action time, narrow application range, etc., to achieve good demulsification effect, demulsification Good milk effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

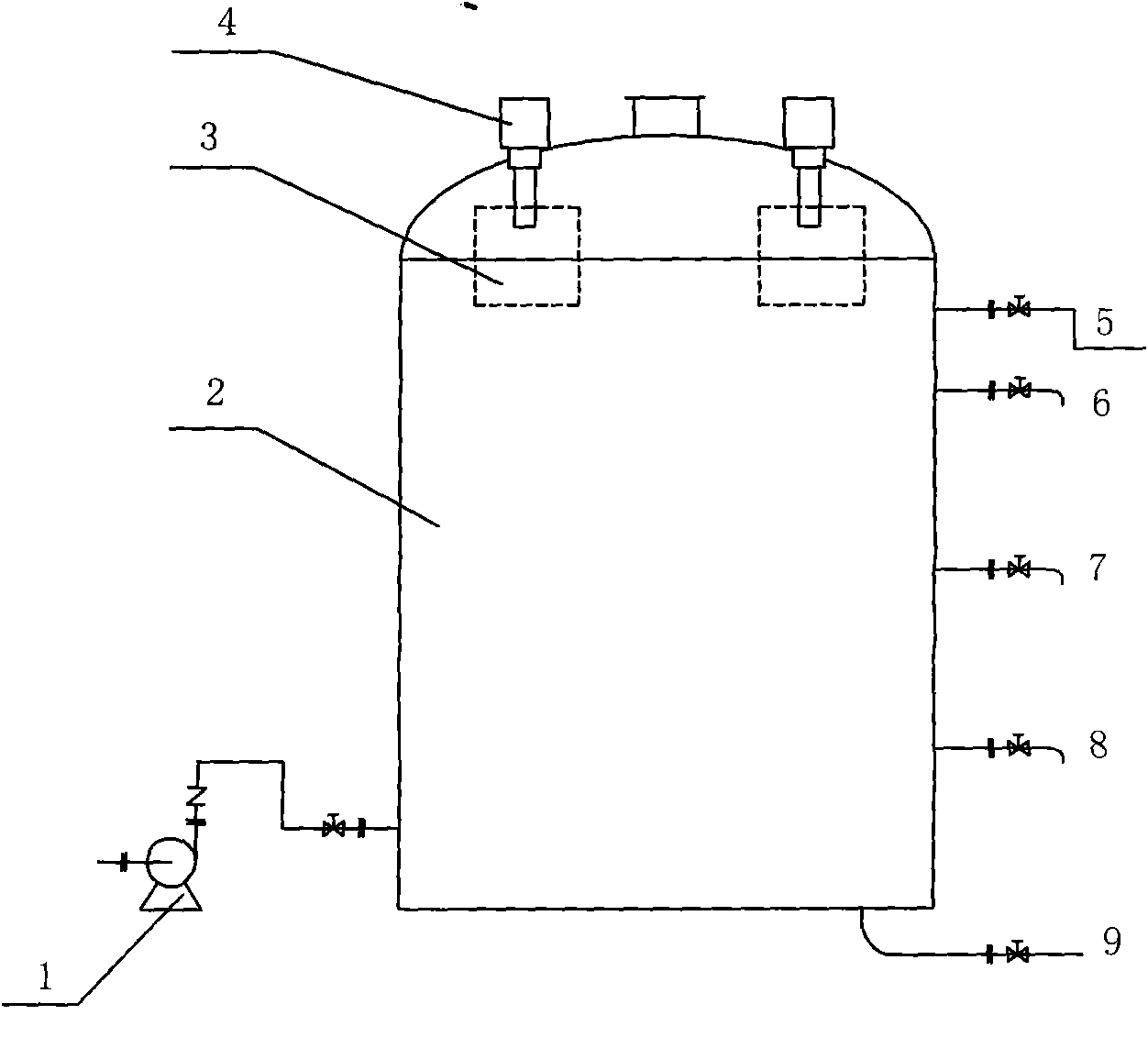

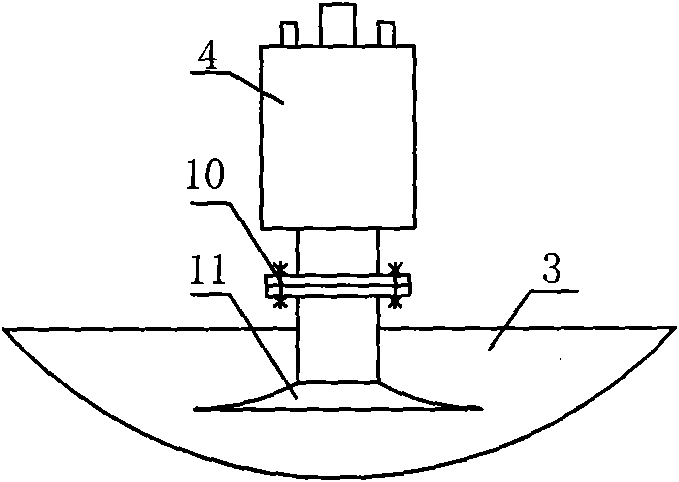

[0033] The raw material for the test is a mixture of crude oil and waste oil from a certain refinery. figure 1 In the process flow shown, a comparative test was carried out between the dehydration mode of single heat deposition and the joint action mode of ultrasonic-heat deposition, and the test data are shown in Table 1. Sedimentation dehydration method: Do not turn on the ultrasonic wave, the dehydration temperature is 50°C, and sample and analyze every 4 hours. Ultrasonic-heat deposition combined action mode: an ultrasonic distributor is designed on the top of the tank, using continuous ultrasonic action, the ultrasonic generator is a magnetostrictive generator, the frequency is 20kHz, and the sound intensity is 5W / cm 2 , the dehydration temperature was 50°C, and sampling and analysis were carried out at intervals of 4 hours.

[0034] Table 1 Comparison of the dehydration method of single heat deposition and the combined action of ultrasonic and heat deposition Test tempe...

Embodiment 2

[0038] The test raw materials, technological process, ultrasonic action mode, frequency, sound intensity, and sampling interval are the same as in Example 1. The dehydration temperature of this comparison test is 60°C. The test data are shown in Table 2.

[0039] Table 1 Comparison of the dehydration method of single heat deposition and the combined action of ultrasonic and heat deposition Test temperature (°C) Settling time (h) Water content after heat deposition (%) Water content after ultrasonic heat deposition (%)

[0040]

[0041]

[0042] Comparing the data of simply using the heating sedimentation method and the ultrasonic-heat sedimentation combined method, it can be seen that, at the same sedimentation time, the water content after removal by ultrasonic is obviously better than that without ultrasonic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com