Preparation of pH responsive two-dimensional thin film and three-dimensional sponge oil-water separation materials and oil-water separation application

A thin film material and responsive technology, applied in the field of oil-water separation, can solve the problems of low separation efficiency, low separation efficiency, high energy consumption, etc., and achieve the effect of simple preparation method, excellent separation performance and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

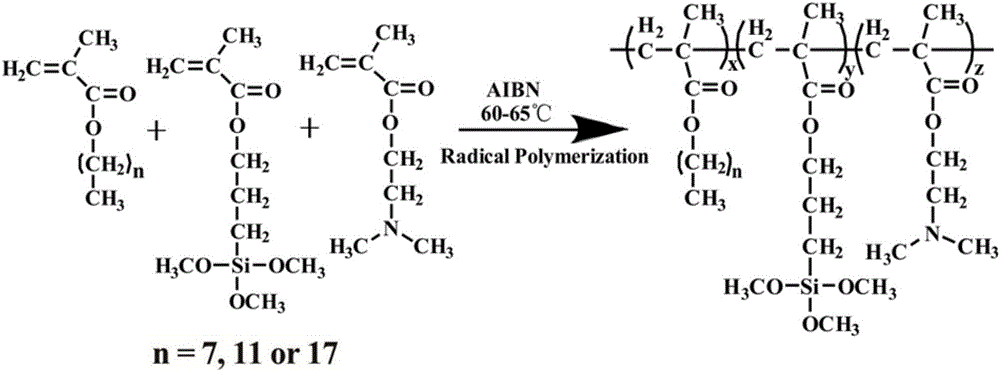

[0059] Preparation of copolymer P:

[0060] Weigh a certain amount of reactant alkyl methacrylate (isooctyl methacrylate, dodecyl methacrylate and octadecyl methacrylate), 3-(trimethoxysilyl ) Propyl methacrylate and dimethylaminoethyl methacrylate in different molar ratios (C 8 , C 12 Alkyl segment: siloxane segment: amino segment = 1:1:4, 4:1:4, 8:1:4, C 18 Alkyl segment: siloxane segment: amino segment = 0.5:1:4, 1:1:4) into a 100ml three-necked flask, add anhydrous toluene as a reaction solvent, and then add an appropriate amount (wt of the total substance mass =0.5%) of the initiator azobisisobutyronitrile (AIBN), and then nitrogen gas was introduced for 30 minutes to remove the air, and then the temperature was raised to 65° C. for 18 hours of reaction. After the reaction was completed, the above solution was precipitated using a large amount of n-hexane, and the precipitates obtained were different alkyl segments (C 8 , C 12 , C 18 ) of the copolymer P, and then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com