Polysaccharide microgels for cleaning water of petroleum and petroleum products and method for using same (variants)

A technology of microgel and PetroChina, applied in chemical instruments and methods, separation methods, general water supply saving, etc., can solve problems such as recovery, separation efficiency decline, and component pollution, so as to improve environmental cleanliness and reduce environmental pollution. The effect of destroying and simplifying the collection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

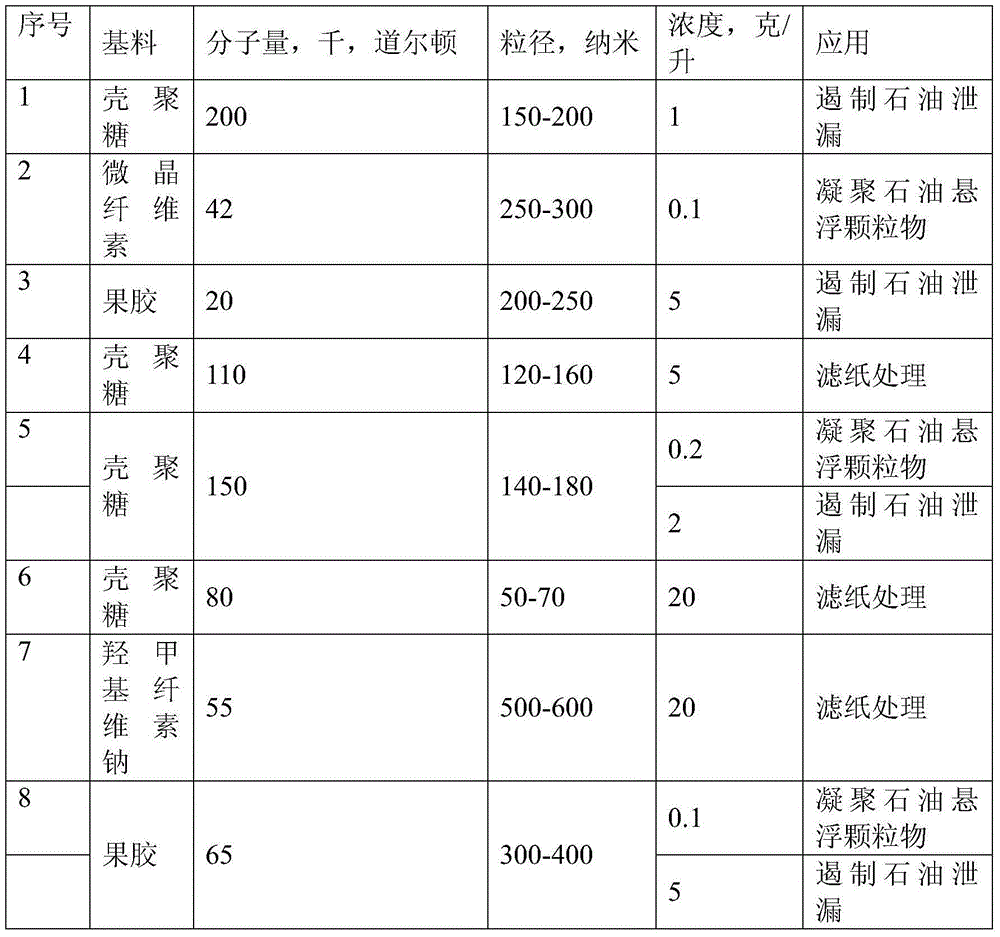

Embodiment 1

[0055] Chitosan (1 g) with a degree of deacetylation of 95% and a molecular weight of 200,000 D was dissolved in 1 liter of 0.01 M hydrochloric acid. To this solution was added 0.05M sodium hydroxide until the pH was 6.8. The prepared chitosan microgel suspension with a particle size of 150-200 nanometers and a concentration of 1 gram per liter is directly used to contain underwater oil spills.

Embodiment 2

[0057] The microcrystalline cellulose produced by acid hydrolysis at a temperature of 75-85° C. for 15 minutes in the presence of hydrochloric acid (concentration: 25%) with a bath ratio of 20 has a molecular weight of 42000 D. Dissolve the cellulose in a 5% system composed of 8% sodium hydroxide, 5% urea and 87% water at a temperature of -5-0°C. The amount of insoluble precipitate was 0%. A solution of monochloroacetic acid (concentration of 25%) added to the solution and a molar ratio of monochloroacetic acid / cellulose basic unit of 1.5:1. The solution was incubated at a temperature of 25°C for 24 hours. The final degree of alkylation substitution of the cellulose was 25%. The particle size of the microgel is 250-300 nm. The solution was diluted with distilled or tap water to a concentration of 0.1 g / l and used to condense suspended particulate matter of petroleum. The pH of this solution is 10.

Embodiment 3

[0059] Pectin (5 g) with a degree of methoxylation of 15% and a molecular weight of 20000D was dissolved in 1 liter of sodium hydroxide (2 g / l) solution. The resulting solution was titrated with 0.2% hydrochloric acid until the solution became cloudy (pH 6.0-6.5). The prepared chitosan microgel suspension with a particle size of 200-250 nanometers and a concentration of 5 g / L was used to contain underwater oil spills.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com