Electromagnetic treatment system and method for oil base drilling fluid waste

A microwave treatment system and oil-based drilling fluid technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve waste pollution and other problems, achieve safe and reliable operation, convenient operation, The effect of complete equipment protection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

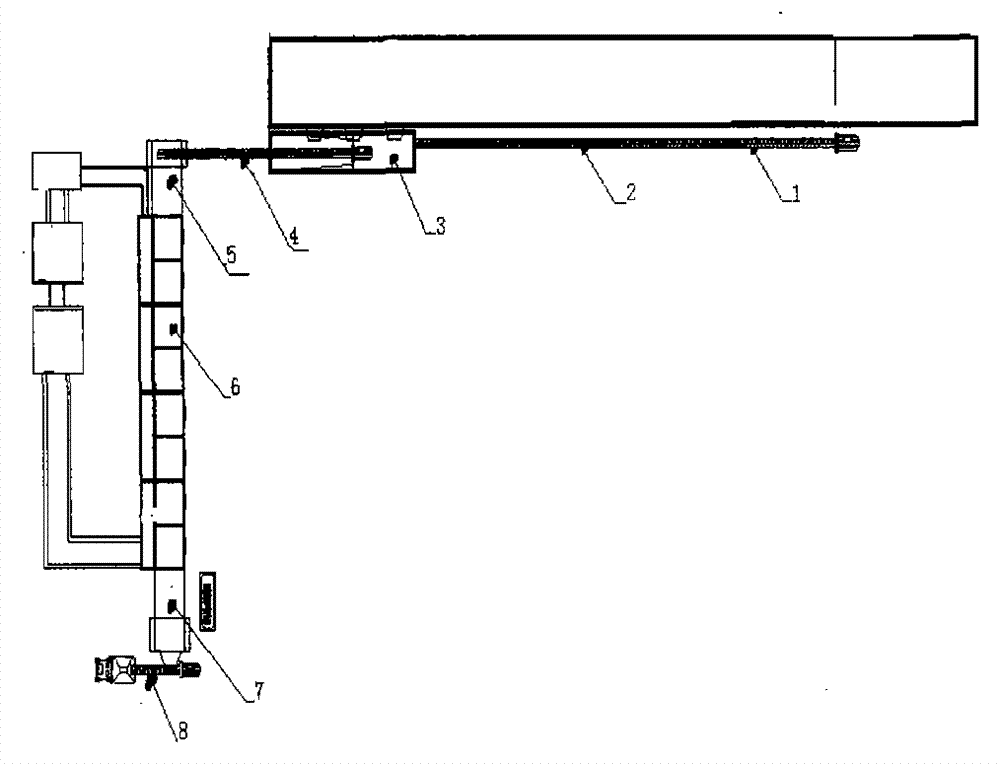

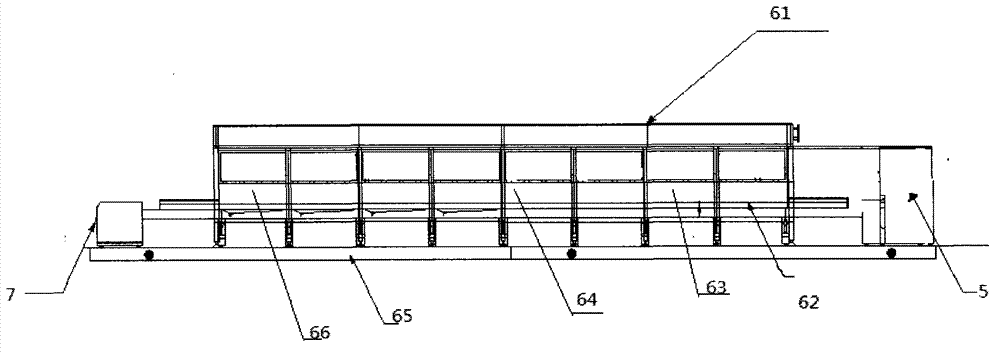

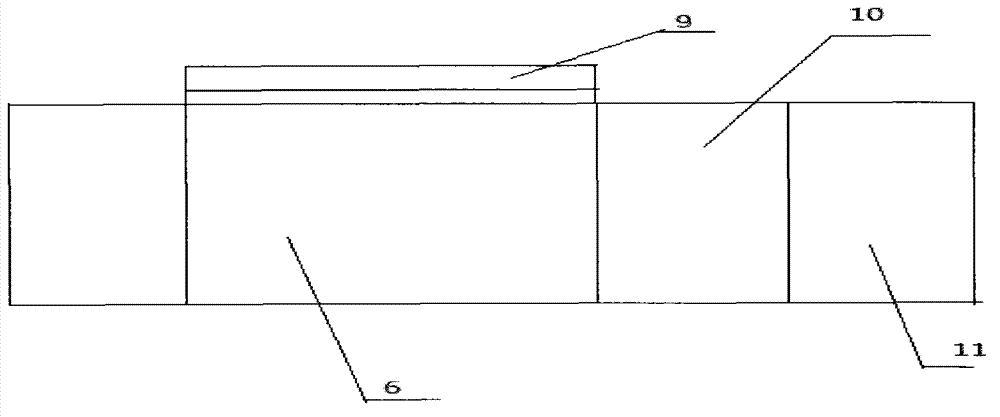

Method used

Image

Examples

Embodiment Construction

[0036] Scale: 5 tons Time: July 2012

[0037] Processing method: remote processing

[0038] Process and results:

[0039] At least 2 tons of oily cuttings are processed per hour, the initial oil content is about 20-30%, and the water content in the soil is about 5%. After microwave heating, water vapor evaporates and dehumidifies, leaving 5% oil after heating. Use microwave equipment to heat oil-containing materials to about 150 degrees. The electromagnetic microwave equipment is used for no more than 12 hours a day, with a rest period in between. The total length of the equipment does not exceed 11 meters, and the width does not exceed 3 meters. The whole machine needs explosion-proof configuration. And ask for rainproof configuration.

[0040] Microwave heating and drying. Before drying, the oil content of the total material is about 30%. After drying, the deoiling rate has reached 95%. The final oil content of the final material is less than 5% after your test. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com