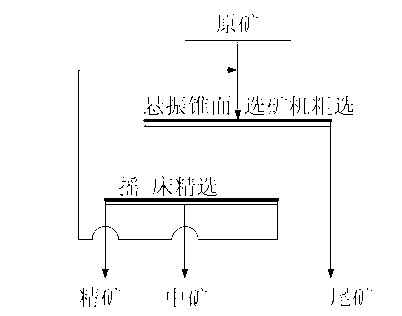

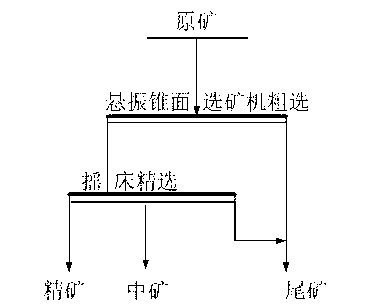

Process of reselecting fine-grained tailings by combining suspension vibration conical surface concentrating machine and table concentrator

A technology of vibrating cone surface and fine tailings, which is applied in solid separation, wet separation, chemical instruments and methods, etc. To solve the problem of low ore grade, it achieves the effects of wide practicability, reduced energy consumption and high enrichment ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

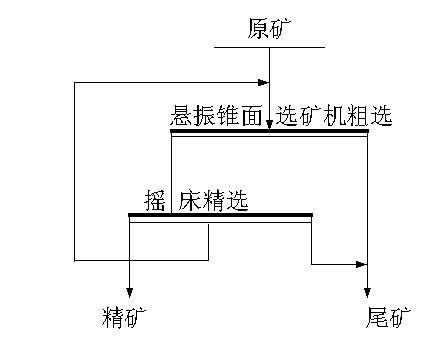

[0016] Embodiment 1: Mineral materials are derived from tin tailings in a certain place, the selected grade of Sn is 0.18wt%, and the technological process is adopted image 3 The method shown is carried out. Firstly, a suspension vibrating conical concentrator is used for roughing. The operating parameters are: the gyratory vibration frequency is 363 rpm, the disk surface movement period is 220 seconds / rotation, and the ore concentration is 23wt%. The tin rough concentrate obtained by the suspension vibrating cone concentrator is then separated by the vibrating cone concentrator using a shaking table to select the tin coarse concentrate to obtain the tin concentrate. The operating technical parameters of the slime shaker are: the stroke is 12mm, and the stroke frequency is 230 times / min.

[0017] Operation Yield(%) grade(%) Recovery rate(%) Enrichment ratio (fold) Suspension Vibration Cone Concentrator Rough Selection 7 1.5 58.5 8.3 Shaker Fea...

Embodiment 2

[0018] Example 2: The ore material is derived from lead-zinc tailings in a certain place, and the process mineralogy properties of the sample are investigated Pb: 0.58%, Zn: 1.82%, using the process flow image 3 The method shown is carried out. Firstly, roughing is carried out with a suspension vibrating conical concentrator. The operating parameters are: the gyratory vibration frequency is 352 rpm, the disc rotation period is 230 seconds / rotation, and the ore concentration is 25%. The lead-zinc rough concentrate obtained by the suspension vibrating cone concentrator is then separated by the vibrating cone concentrator with a shaker to obtain lead-zinc concentrate and lead-zinc medium ore. The operating technical parameters of the slime shaker are a stroke of 12mm and a stroke rate of 230 strokes / min.

[0019]

[0020] Operation Yield(%) grade(%) Recovery rate(%) Enrichment ratio (fold) Suspension Vibration Cone Concentrator Rough Selection 5.88 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com