Oil-in-water emulsion having improved sensory properties

a technology of oil-in-water emulsion and sensory properties, which is applied in the field of compositions, can solve the problems of introducing constituent ingredients of cosmetic formulations, unsatisfactory sensory results,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example iv-1

“Day Fluid” Formulation

Formula

[0176]

AComposition (A1)3.00%MONTANOV ™ 141.50%DUB ™ BB2.00%Butyrospermum Parkj (Bio)1.50%DUB ™ MUG1.50%Squalane3.00%Caprylic / capric triglyceride6.00%DUB ™ ISIP3.00%DERMOFEEL ™ Toco 700.10%BWaterQ.S. 100.00%Aqueous Hordeum Vulgare extract3.50%Xantham Gum0.60%CGEOGARD ™ 2210.60%AQUAXYL ™3.00%DERMOSOFT ™ 7000.50%SodaQ.S. pH = 5.5

Procedure: phase B is added to phase A at a temperature of 80° C., with stirring with a turbine of the rotor / stator type, then cooled with moderate stirring with a mechanical stirrer equipped with a stirring impeller of the anchor type at a speed of 80 rev / min. Phase C is then added in the same conditions of stirring at a temperature of 40° C.

example iv-2

Dermopurifying Makeup-Removal Milk

Formula

[0177]

AWaterQ.S. 100.00%Amigum (Sclerotium gum)0.15%BWaterQ.S. 30.00%LIPACIDE ™ C8G1.00%Soda at 48%Q.S. pH = 5.5PROTEOL ™ OAT2.00%Glycerol2.00%CComposition (A1)4.00%Caprylic / capric triglyceride4.00%Squalane4.00%Corylus Nucifera (Hazel) seed oil2.00%Prunus Amygdalus Dulcis (Sweet almond) oil2.00%Beeswax0.30%DAqueous Hordeum Vulgare extract10.00% GEOGARD ™ 2210.60%DERMOFEEL ™ Toco 700.10%

Procedure: phases A and B are prepared separately beforehand, then phase A is added to phase B at a temperature of 80° C. with mechanical stirring with a stirrer equipped with an impeller of the anchor type at a speed of 80 rev / min. Phase C is then added to the mixture of phase A+B at a temperature of 80° C. with stirring with a rotor / stator turbine and is then cooled with moderate stirring. Phase D is then added at 40° C.

example iv-3

Intense Firmness Body Milk

Formula

[0178]

AWaterQ.S. 100.00%Soda at 48%Q.S. pH = 5.5AVICEL ™ PC 6110.40%Glycerol2.00%BComposition (A1)2.00%DUB ™ ISIP4.00%Caprylic / capric triglyceride7.00%Carthamus Tinctorius (Safflower) oil1.00%SEPILIFT ™ DPHP1.00%CAqueous Hordeum Vulgare extract10.00% DGEOGARD ™ 2210.60%DERMOFEEL ™ Toco 700.10%Fragrance0.10%

Procedure: phase A is added to phase B at 80° C. with stirring with a rotor / stator turbine. The mixture obtained is then cooled to a temperature of 40° C. with moderate stirring using a mechanical stirrer equipped with an impeller of the anchor type at a speed of 80 rev / min. Phase C is then added at 40° C., then phase D is added at 40° C.

MONTANOV™ 14 is a mixture of myristic alcohol and myristyl polyglucosides marketed by the company SEPPIC as emulsifier.

DUB™ BB is behenyl behenate marketed by the company STEARINERIE DUBOIS.

DUB™MUG is glycerol undecylenate marketed by the company STEARINERIE DUBOIS.

DUB™ISIP is isopropyl isostearate marketed by the ...

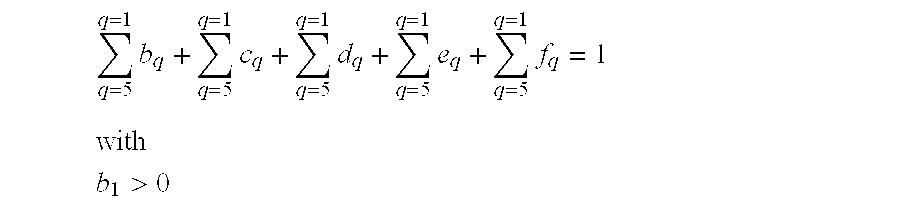

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com