Plate electrode static coalescer

An electrostatic coalescence and flat electrode technology, which is applied in the direction of separation of liquid by electricity, dehydration by electricity/magnetism/demulsification, etc., can solve the problems of difficult to achieve production requirements, large equipment cost and floor space, poor safety and stability, etc. To achieve the effect of improving oil-water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

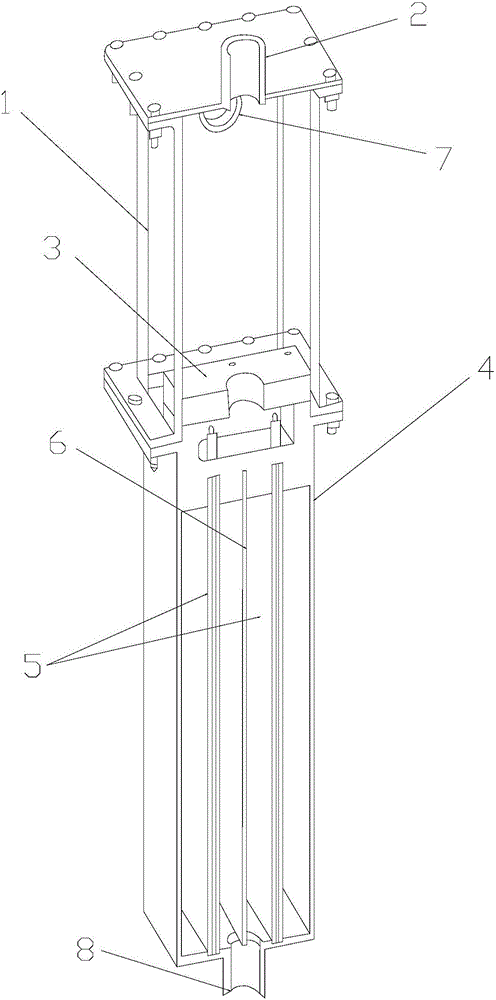

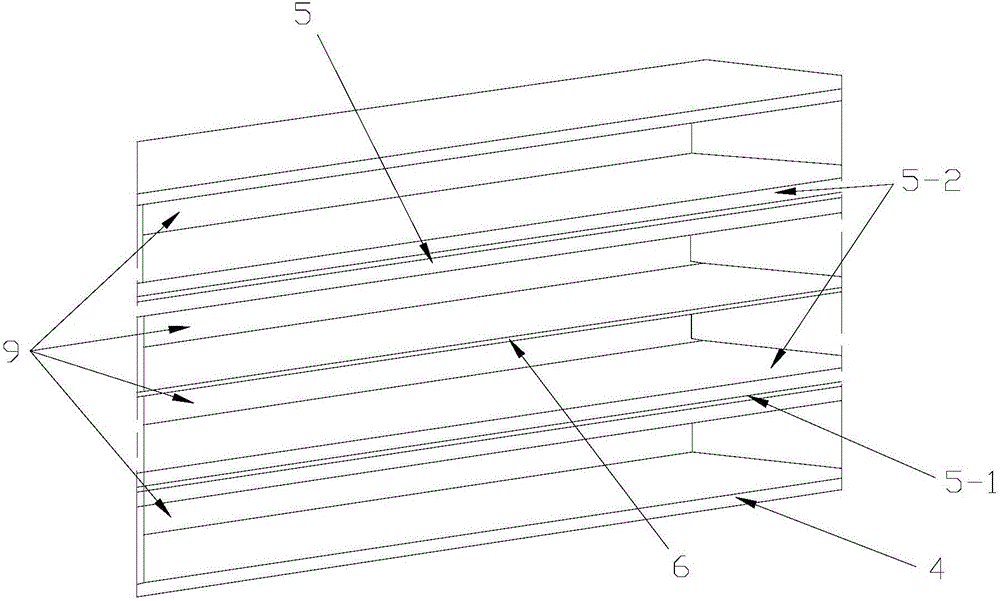

[0016] Such as Figure 1~2 As shown, a flat electrode electrostatic coalescer, the upper part of the coalescer is a high-voltage electric input section, and its lower part is a coalescing section. The high-voltage electric input section has an observation room 1 made of insulating plexiglass. The upper end of the room 1 is provided with a high-voltage insulated wire inlet 2, the bottom of the observation room 1 is provided with an insulated junction slot 3, and the bottom of the observation room 1 is provided with a stainless steel shell 4, the shell 4 and the insulated electrode 5 and the bare electrode 6 located in it The coalescing section is formed, and the insulated electrode 5 is connected to the high-voltage end of the external transformer through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com