Combustion optimization with inferential sensor

A fuel, fuel ratio technology, applied in the direction of burner, combustion type, control combustion, etc., can solve problems such as unsatisfactory and accurate air/fuel ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Detailed description of the preferred embodiment

[0015] The controller system of the present invention is based on pre-control technology. Given the relatively fast dynamic nature of the boiler and the scaling constraints imposed by plant lifetime factors, the present invention focuses on power and heat generating operations. Following the use of pre-control techniques and proportional optimal control (ROC), the basic idea for the next step is tight dynamic coordination of the selected controlled variables.

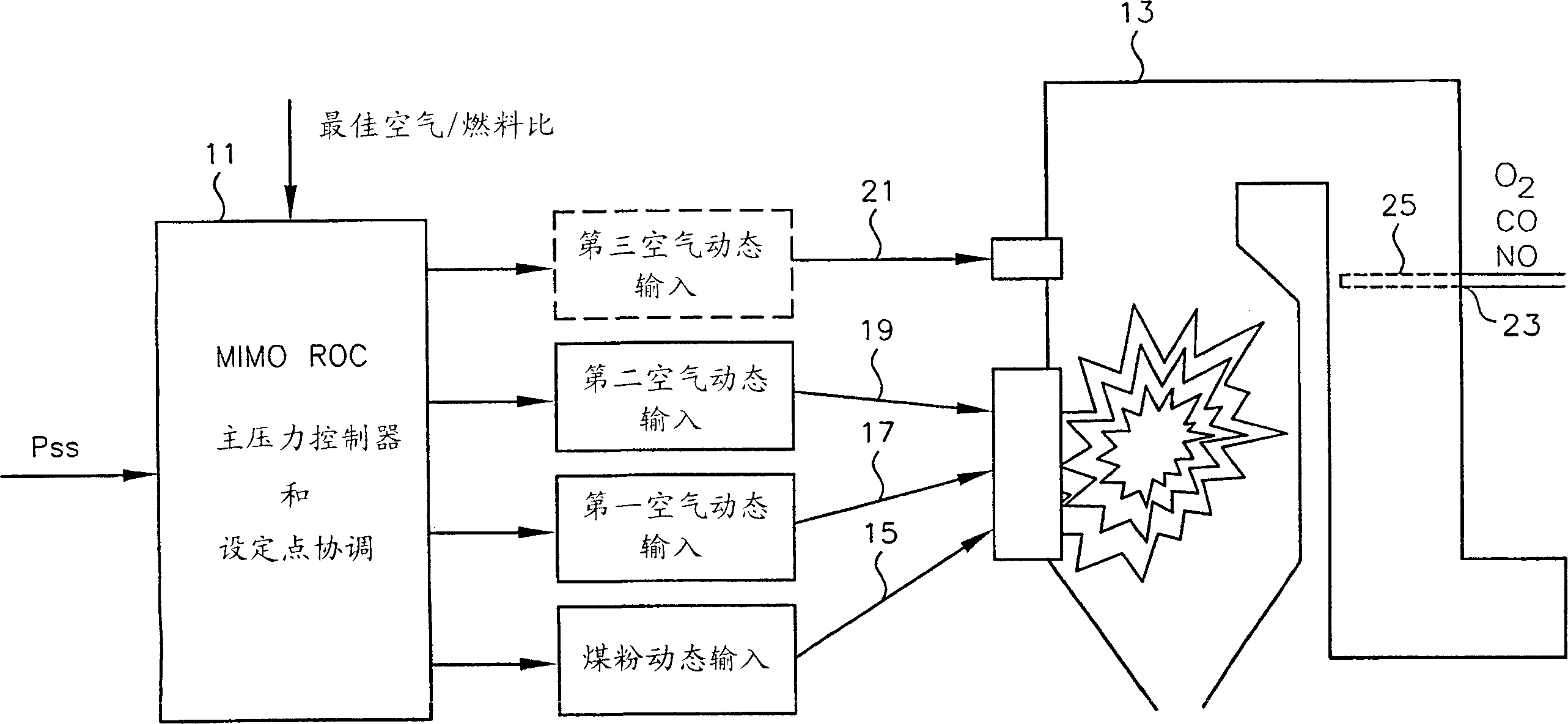

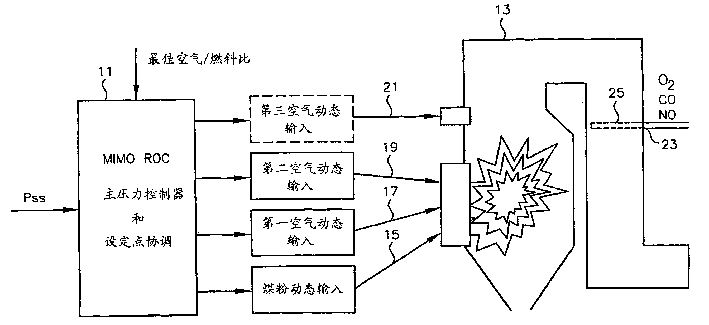

[0016] attached figure 1 A typical application of MIMO ROC controller 11 in pressure control using simultaneous combustion (air / fuel ratio) optimization is described. in the attached figure 1 In the boiler, air and fuel are input to the boiler 13, and the fuel (pulverized coal) input 15 and the first air input 17 are controlled by the controller 11. In addition to these two basic factors that constitute the air / fuel ratio in the boiler, a second 19 and, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com