Air circulated heating and purifying device for coal-fired furnace and coal-fired furnace using air circulated heating and purifying device and processing method for coal-fired furnace

An air circulation and purification device technology, which is applied in the field of coal-fired furnaces, can solve the problems of high cost and low heating thermal efficiency, and achieve the effects of avoiding excessive temperature, avoiding coking, and improving heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

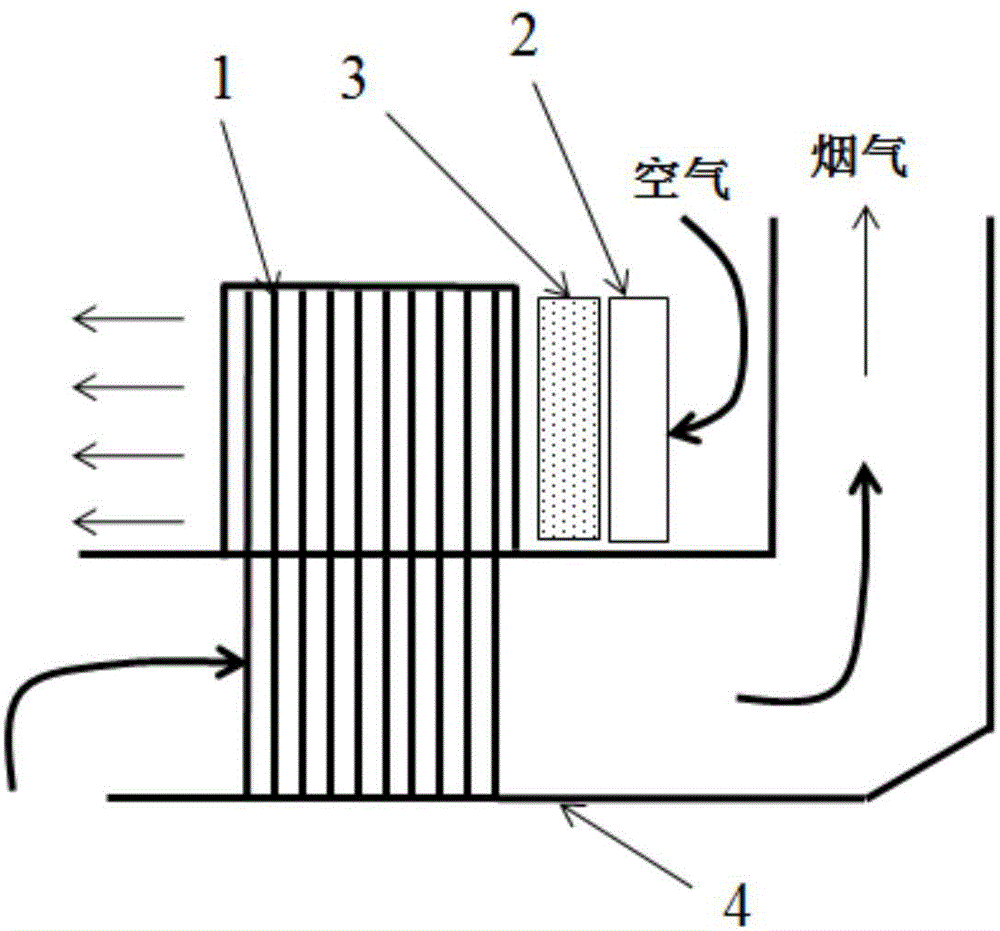

[0064] This embodiment provides an air circulation heating and purification device for a coal-fired stove, such as figure 2 As shown, the air circulation heating and purification device includes a heat pipe heat exchanger 1, an induced draft fan 2 and an air filter device 3, the heat pipe heat exchanger 1 has a built-in heat exchange tube, and the heat exchange tube is filled with a heat transfer material; The flue gas outlet of the stove leads out the flue gas discharge pipe 4 placed horizontally, the lower part of the heat pipe heat exchanger 1 is inserted into the flue gas discharge pipe 4, and the upper side of the heat pipe heat exchanger 1 is provided with an air inlet, which is connected with the air. An air outlet is arranged on the opposite side of the inlet, the induced draft fan 2 is arranged at the air inlet, and the air filter device 3 is arranged at the air inlet.

[0065] Wherein, the heat transfer material is water, and the air purification material is built in...

Embodiment 2

[0067] This embodiment provides an air circulation heating and purification device for a coal-fired stove, such as image 3 As shown, the structure of the air circulation heating and purification device refers to Example 1, the difference is that: the induced draft fan 2 is arranged at the air outlet, the air filter is arranged at the air outlet, the heat transfer material is Freon-21, and the air purification The material is synthetic fiber.

Embodiment 3

[0069] This embodiment provides an air circulation heating and purification device for a coal-fired stove. The structure of the air circulation heating and purification device refers to Example 2, except that the heat transfer substance is methanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com