Apparatus for capturing heat from a stove

a technology for capturing heat and stoves, applied in the field of apparatus for capturing heat from stoves, can solve the problems of tars and creosotes accumulating, the merit of trying to recover heat from the chimney gasses of efficient stoves, and dramatically reducing the convective ‘draw’ required for good combustion, so as to save costs for the householder and reduce carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]An embodiment of the invention will now be described in detail, by way of example, and with reference to the accompanying drawings.

[0038]As an introduction to the embodiment, operation of a modern wood-burning stove will now be discussed.

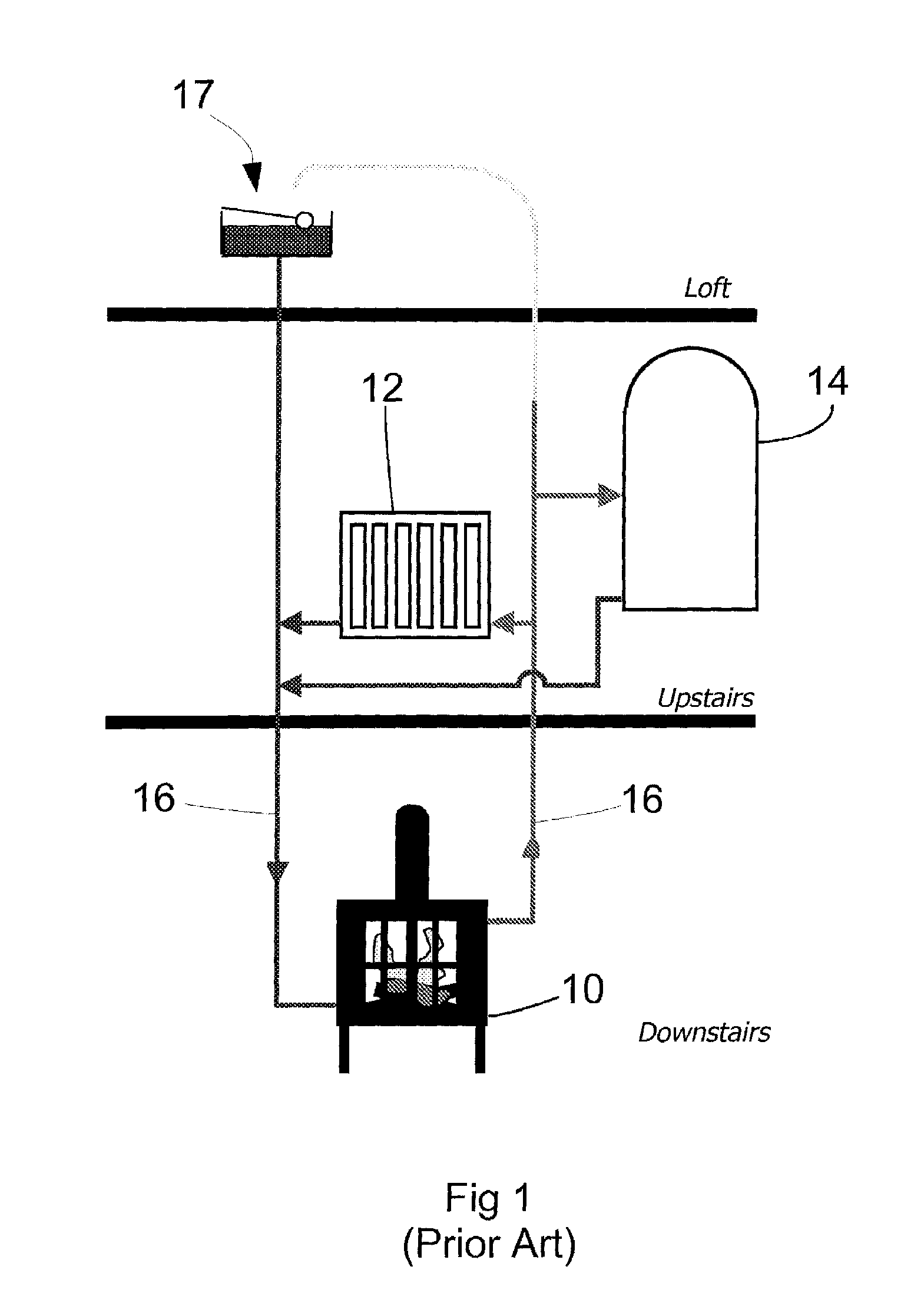

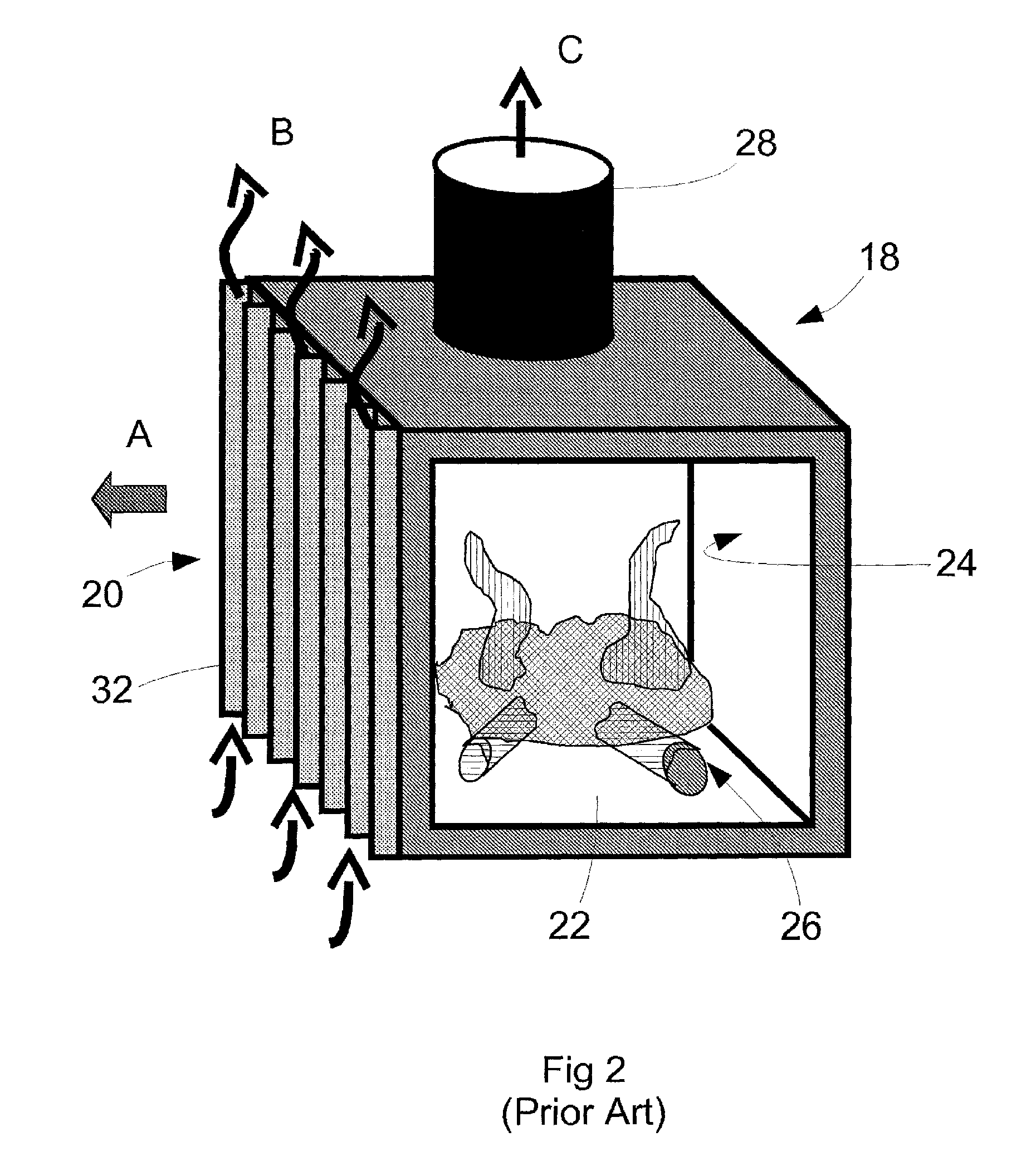

[0039]Heat transfer from a stove to its surroundings (typically, a room in a building) occurs by way of radiation (A) and convection (B) from the surfaces of the stove to air within a room in which the stove is located and there is also heat lost (C) up the chimney 28. For a well-designed stove, the chimney loss should be less that 30%, and may be less than 20% for some of the most efficient new designs. The proportions of radiative and convective heat transfer can vary depending on the design and temperature of the stove sides.

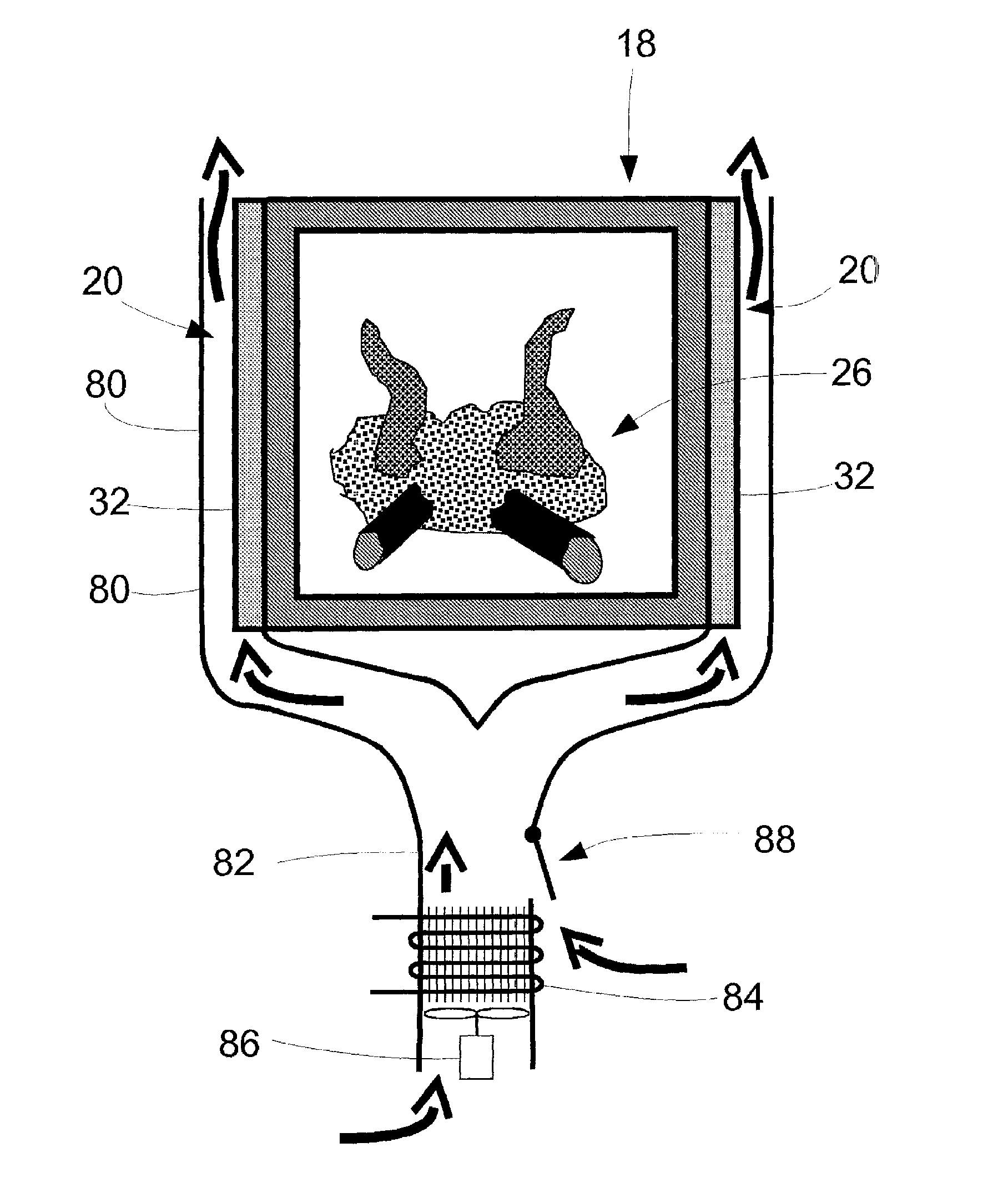

[0040]For a stove 18 with finned sides 20, as shown in FIG. 2, the majority of the heat generated by the burning fuel is transferred by convection from the stove sides 20, with a higher proportion of radiant heat transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com