Variable pitch fuel supplier and an oven for use with the same

a biomass fuel oven and variable pitch technology, which is applied in the field of variable pitch fuel suppliers and biomass fuel ovens, can solve the problems of large noise, high cost of feeding motors, and high clogging of fuel tubes, and achieve the effect of reducing the clogging of biomass fuel granules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

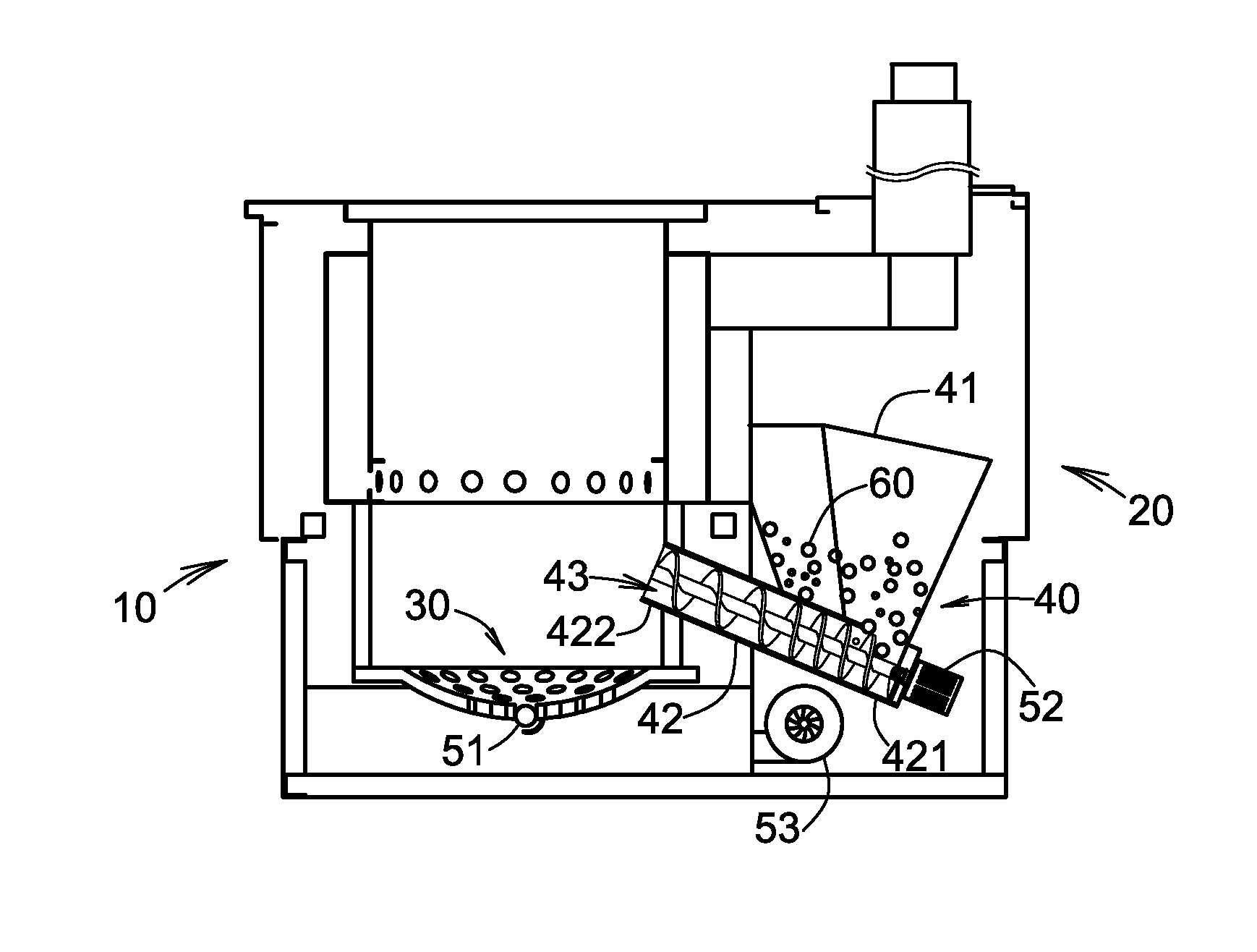

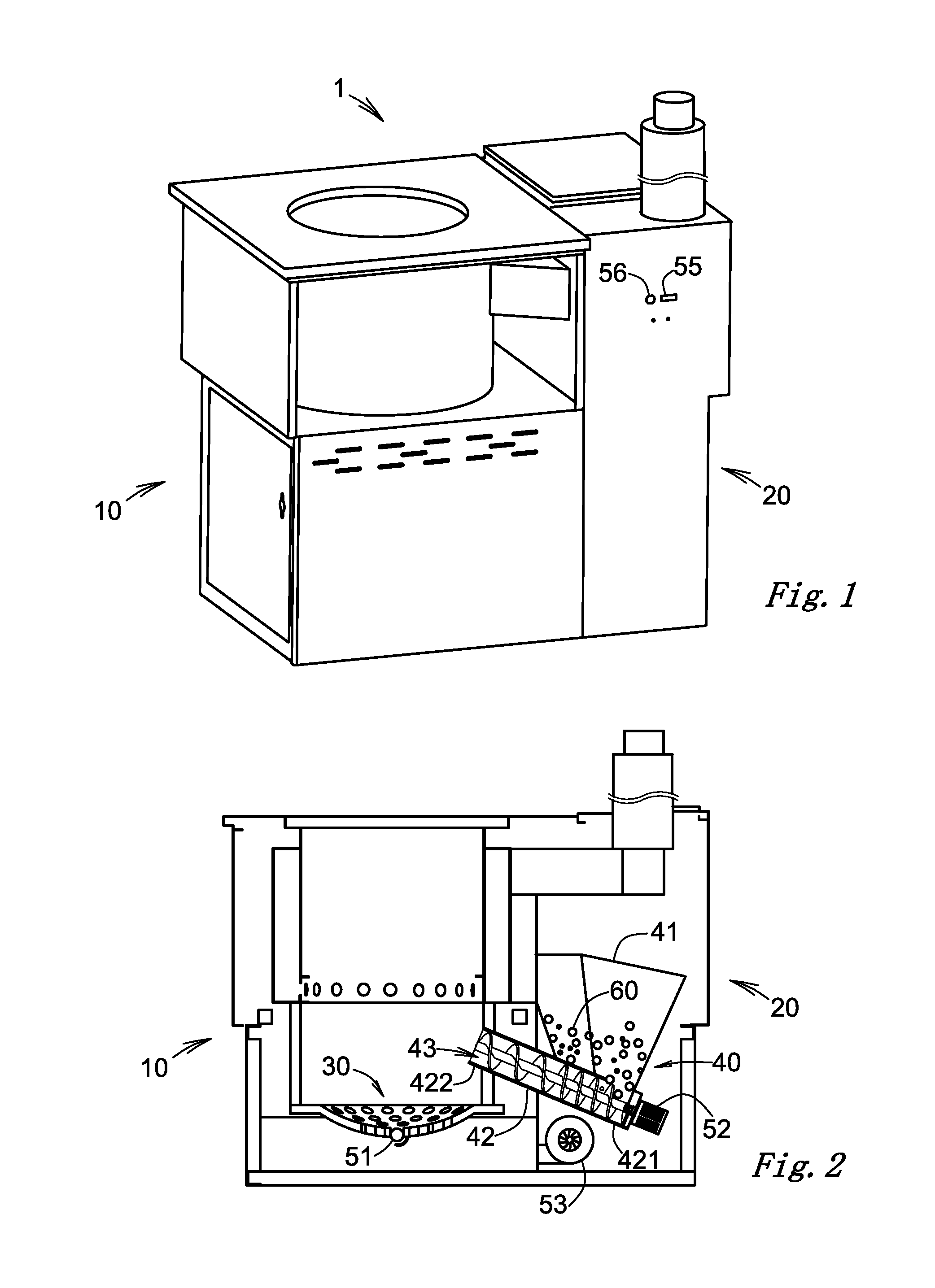

[0023]Shown in FIG. 1 is the preferred embodiment of the invention, an oven for use with a variable pitch fuel supplier. The oven has a body 1 which is able to be levelly placed on the ground. The body 1 has a combustion cabinet 10 and an auxiliary equipment cabinet 20.

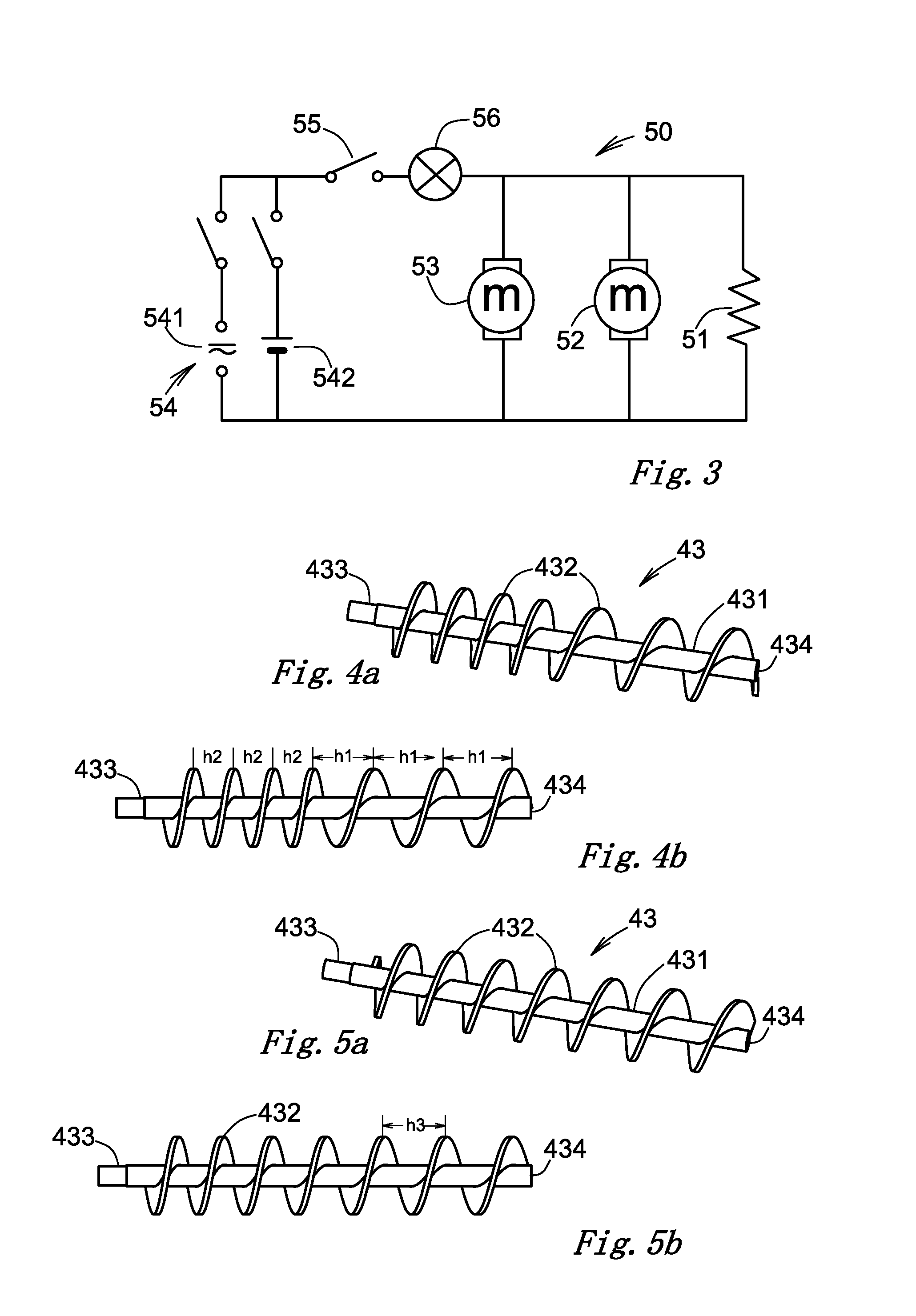

[0024]Together with reference to FIG. 2, the combustion cabinet 10 has a burner 30 received therein. The auxiliary equipment cabinet 20 has a fuel supplier 40 and an electrical equipment 50 received therein. The fuel supplier 40 has a hopper 41, a fuel tube 42, and a rotary vane feeder 43 rotatably received in the fuel tube 42. The electrical equipment 50 has a feeding motor 52 for driving the rotary vane feeder 43. The fuel tube 42 is of cylindrical and has a feeding end 421 in the auxiliary cabinet 20 and a discharge end 422 above the burner 30. The rotary vane feeder 43 is received in the fuel tube 42.

[0025]With reference to FIGS. 4a and 4b, the rotary vane feeder 43 has a central shaft 431 and a spiral vane 432 sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com