Automatic biological material combusting multipurpose furnace

A biological raw material, multi-purpose furnace technology, applied in household furnaces/stoves, combustion air/flue gas circulation of furnaces, applications, etc., can solve the problems of high consumption of heating furnaces, pollute the environment, unsafe, etc., and reduce carbon evaporation. , good effect, widely used effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

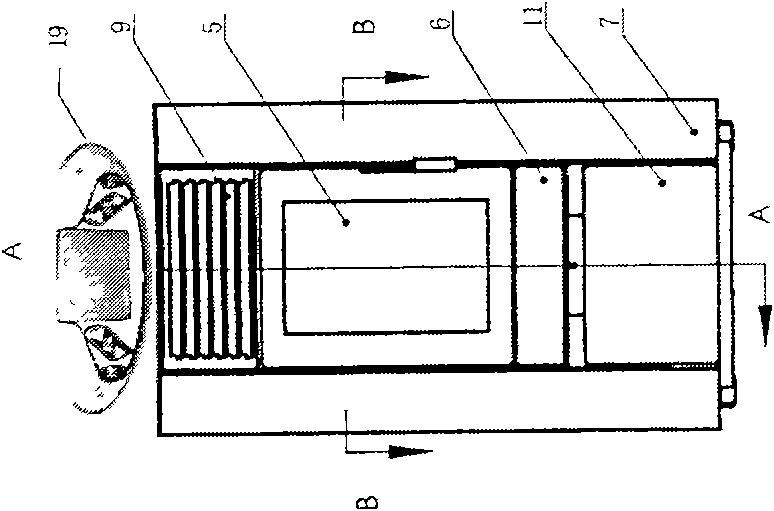

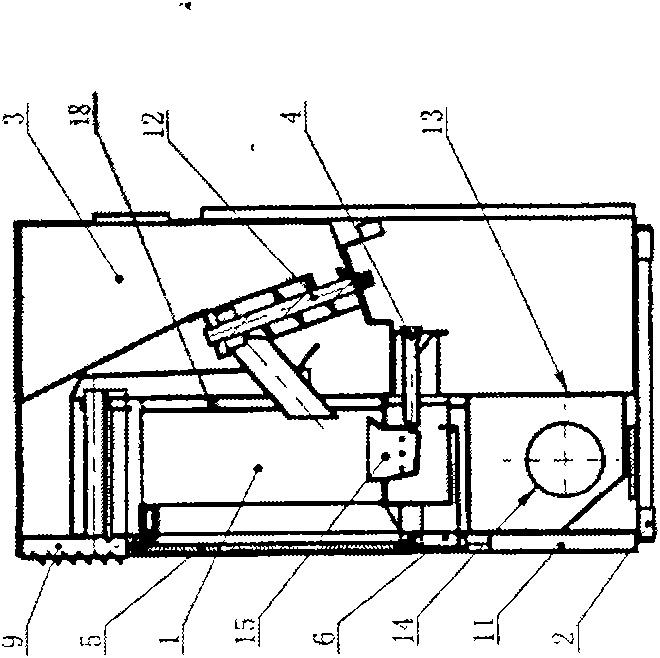

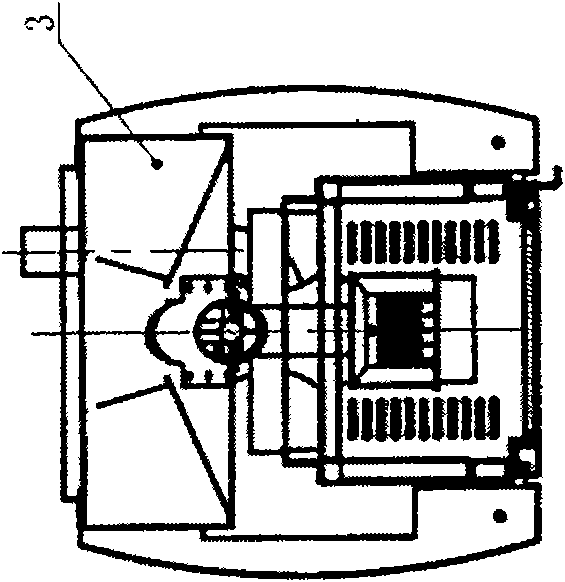

[0019] Example 1, see figure 1 , 2, 3, 4, 5, 6, 7, using 2-3mm steel plate and stainless steel plate to form a sealed furnace body 1 through stamping and welding, the pressure in the furnace body 1 is negative pressure, and a chassis 2 is installed at the bottom of the furnace body 1 , the chassis 2 can adjust the rubber pad, which has the function of anti-skid and stability in installation and use, and protects the ground from wear and tear. A fuel hopper 3 is installed on the upper part of one side of the furnace body 1, which can hold 20Kg of fuel. Fuel temperature sensor 28 is installed on fuel bucket 3, is connected with automatic control device 13 by circuit, prevents high temperature, body of heater is overheated, and operating program is closed, and fuel consumption sensor 30 is installed under fuel bucket 3, and fuel bucket 3 is connected with automatic The feeding device 12 is joined, and the automatic feeding device 12 is driven by the fuel supply motor 36, the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com