Single sliding door forward-pull and backward-push controlled pot table type heating boiler

A heating furnace and sliding door technology, which is applied in the field of boiler platform heating boilers, can solve the problems of increased manufacturing difficulty, inconvenient operation, and blocked passages, etc., and achieves low labor and material costs, low processing and manufacturing difficulty, and avoids excessive humidity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

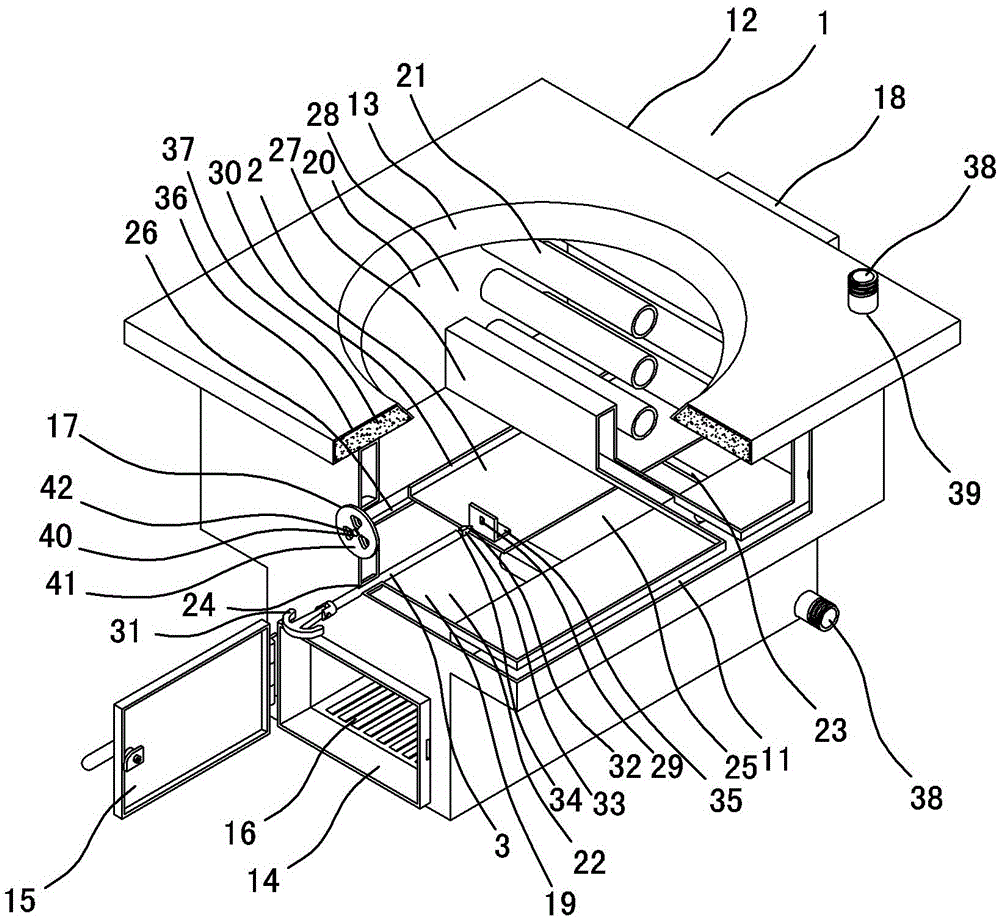

[0008] Embodiment one, such as figure 1 As shown, it includes a pot table boiler furnace body 1 with water jackets 11 on the surrounding walls and a pot port 13 on the top wall 12. The lower part of the front wall of the furnace body 1 is provided with a furnace port 14 and a furnace door is hingedly installed. 15. The bottom of the furnace body 1 is provided with a furnace grate 16 located at the rear of the furnace mouth 14. The front wall of the furnace body 1 is provided with a vent located below the top wall 12 and an air regulating valve 17 is installed. The rear wall of the furnace body 1 The upper part is provided with a smoke outlet and is connected with a chimney 18 located outside the rear wall of the furnace body 1. The position between the bottom of the furnace body 1 and the middle part of the furnace body 1 in the furnace body 1 is the lower furnace chamber 19, the middle part of the furnace body and the furnace body. The position between the top walls 12 is the...

Embodiment 2

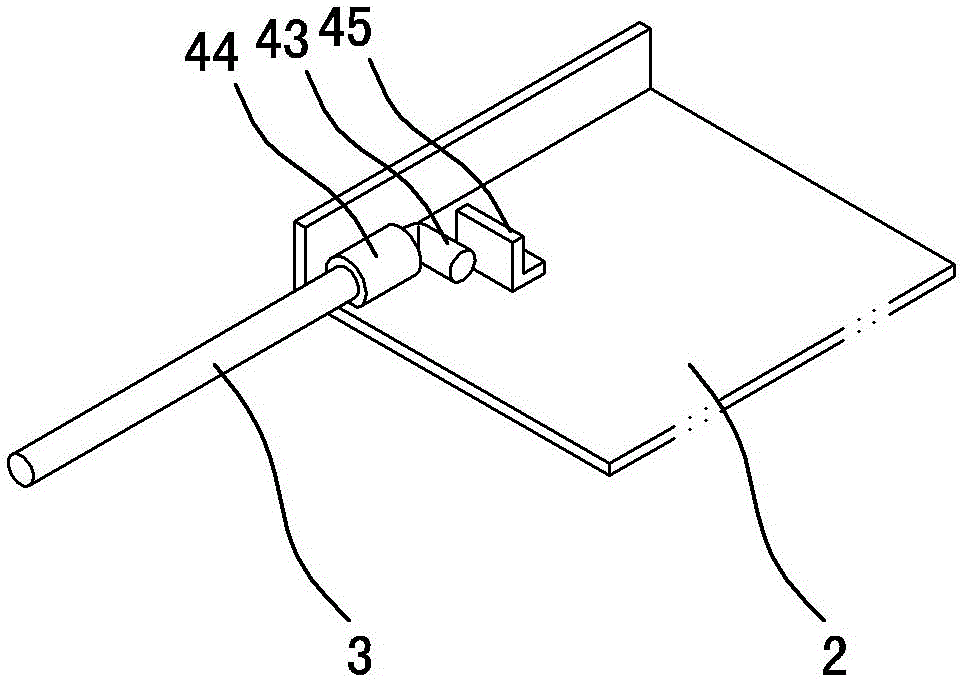

[0017] Embodiment two, such as figure 2 As shown, the difference from Embodiment 1 is that the push-pull rod 3 is positioned at the front end portion of the body of furnace 1 to be provided with a horizontal hook 43, and the part between the push-pull rod handle 31 and the cross-hook 43 is the same as the circular push-pull rod hole 24. Cooperating round rod section, the front position of sliding door 2 left side or right side is provided with the push-pull rod sliding sleeve 44 that axial direction is identical with sliding door 2 sliding direction, slides sleeve on the push-pull rod 3 round rod section, on the sliding door 2 The position of the push-pull rod 3 in the push-back direction is provided with a cross-hook block 45 that is spaced apart from the push-pull rod sliding sleeve 44 and is greater than the diameter distance of the cross hook 43 and is laterally staggered with the push-pull rod slip sleeve 44. Can block cross hook 43 and make push-pull bar 3 push back sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com