Refuse processing method and apparatus

A treatment device and treatment method technology, which is applied in the field of waste treatment methods and treatment devices, can solve the problems of waste headaches such as cost, high cost, and inability to find waste treatment devices on the market, and achieve the goal of reducing weight and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

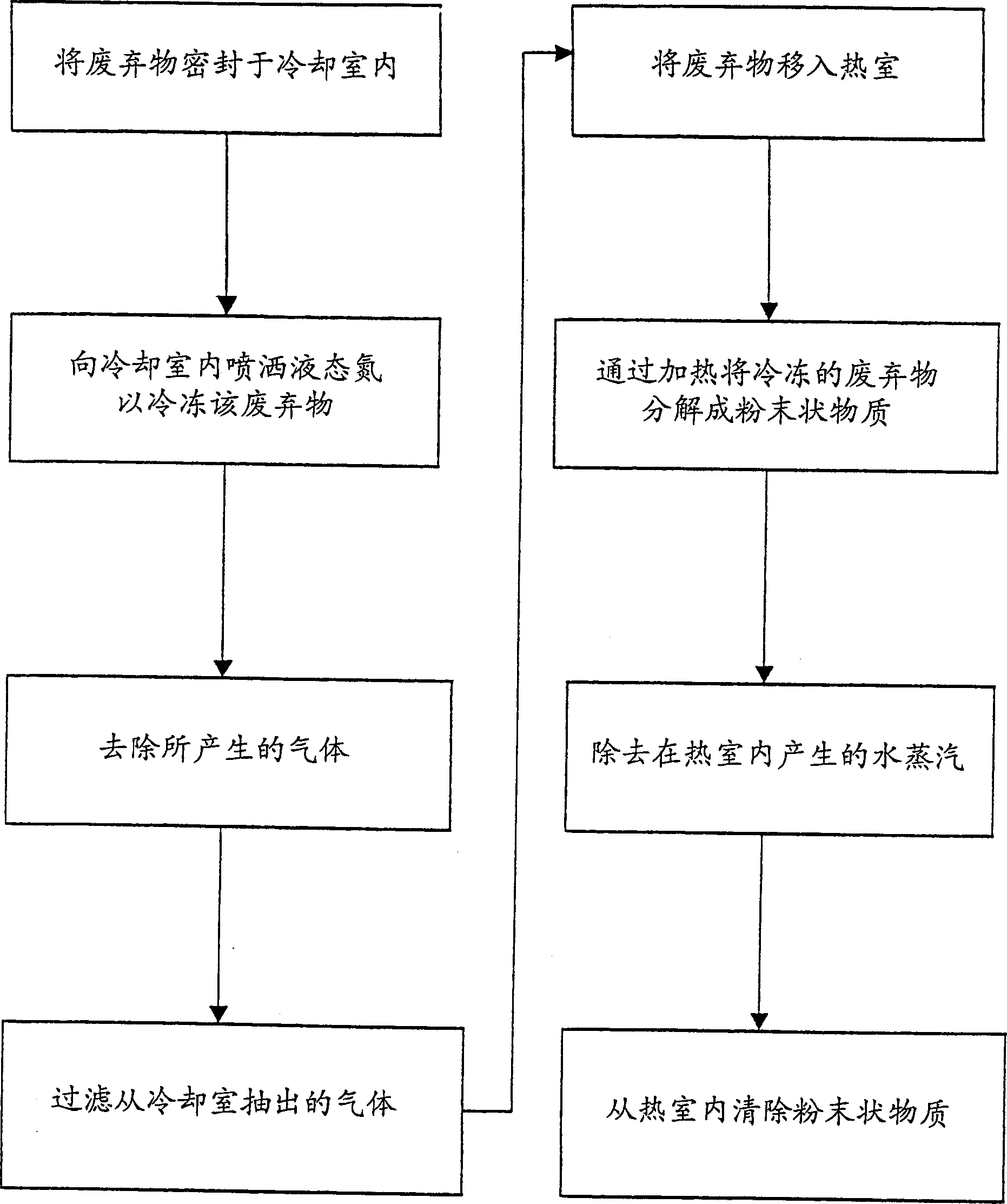

[0035] see figure 1 , The present invention provides a smokeless waste disposal method that does not involve incineration and can reduce the volume and weight of the waste into a powdery and sterile substance that can be used as a plant fertilizer. Waste disposal method of the present invention has included following steps:

[0036] Step A: Put a predetermined amount of waste in the cooling chamber and then seal it. This cooling chamber should be insulated. The larger the volume of waste, the larger the cooling chamber.

[0037] Step B: Surround the waste with a predetermined amount of liquid nitrogen in the cooling chamber for a predetermined time, rapidly cooling the waste to below -128.9°C.

[0038] Liquid nitrogen is commonly used in the frozen food industry because liquid nitrogen can quickly freeze any substance to very low temperatures. Spray liquid nitrogen around the waste in a closed cooling chamber until all waste is exposed to liquid nitrogen both on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com