A kind of environment-friendly disposal process of titanium tetrachloride residual material liquid

A titanium tetrachloride and residual material technology, applied in the field of titanium tetrachloride residual material disposal, can solve the problems of simple and extensive, smoky, pungent odor, etc., and achieve fully automatic or semi-automatic, highly clean dust dispersion , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

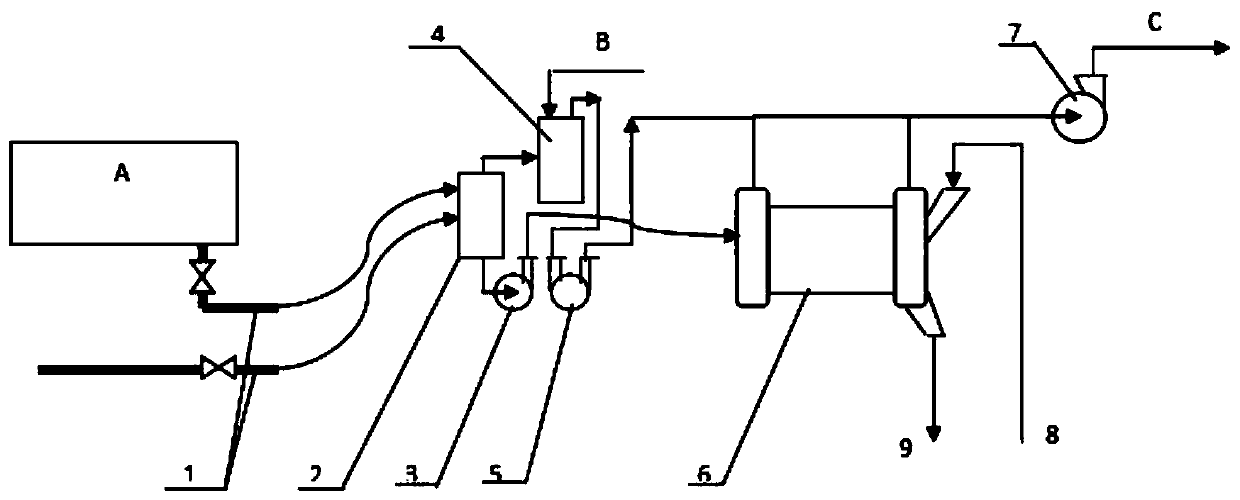

[0043] In combination with the above-mentioned equipment, the specific operation steps of the titanium tetrachloride residual liquid environmental protection treatment process of the present invention are as follows:

[0044] 1) Connect the vacuum suction device and the discharge port (1) of the production device; the inside of the scrubber (4) contains a sodium hydroxide solution with a concentration of 5%-30% by weight; turn on the sanitary fan (7);

[0045] 2) Before the raffinate suction starts, start the rotary reactor (6), make the rotary reactor (6) rotate forward at an appropriate speed, and put in an appropriate amount of free water from the lime powder feed port (8) with a content of 5% active slaked lime powder; the active slaked lime powder is obtained by digesting quicklime at a high temperature above 100°C and does not contain agglomerates larger than 20mm.

[0046] 3) The lime powder loading in the rotary reactor (6) reaches the rated loading volume, and after f...

Embodiment 2

[0053] The same process steps and process parameters as in Example 1 were adopted, except that the free water content of the active slaked lime powder in 2) was changed to 10%.

Embodiment 3

[0055] The same process steps and process parameters as in Example 1 were adopted, except that the free water content of the active slaked lime powder in 2) was changed to 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com