Oven without dust rise

a technology of ovens and ovens, applied in the field of ovens without dust rise, can solve the problems of difficult ash in burning and oven heating zones to fly out,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

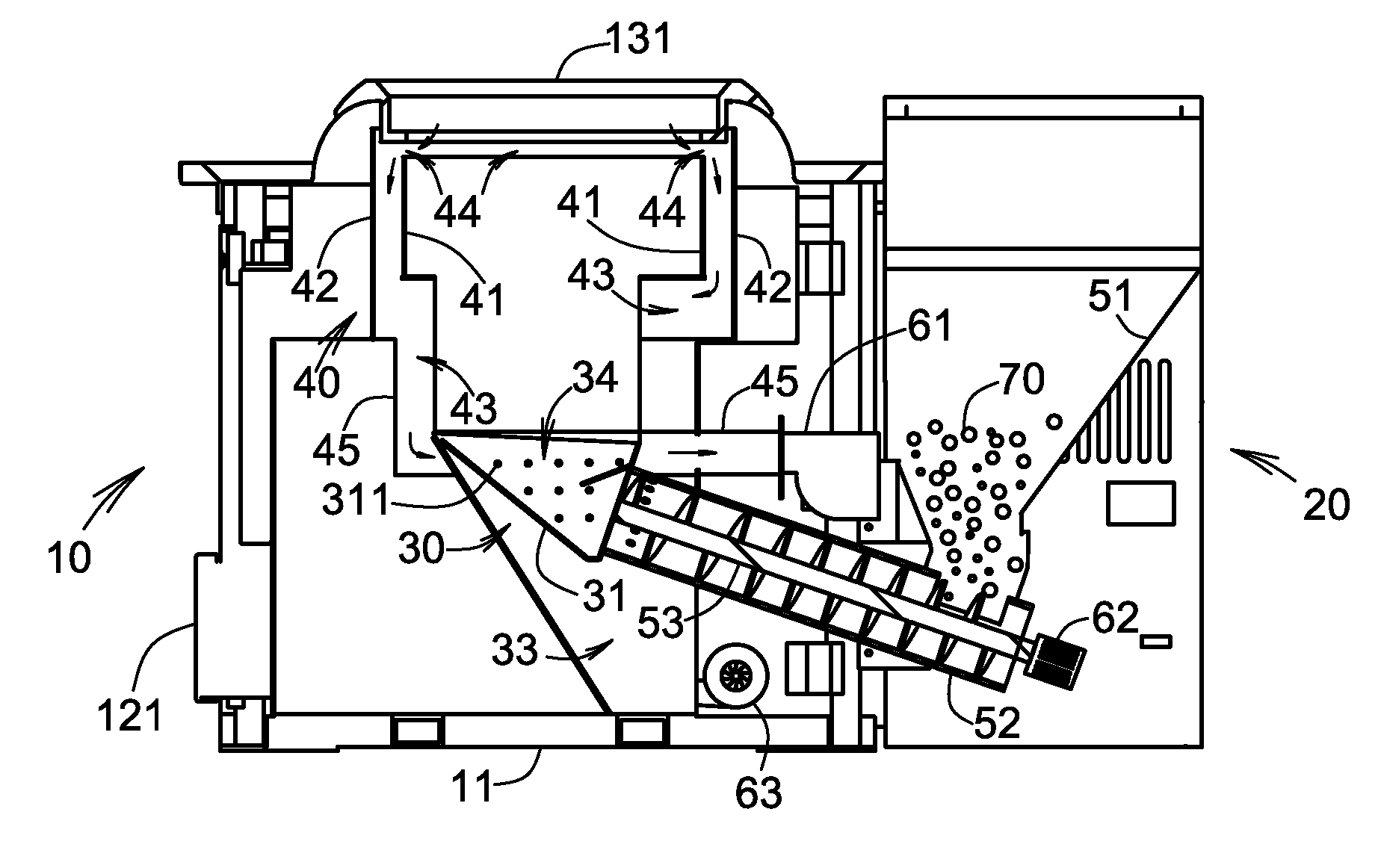

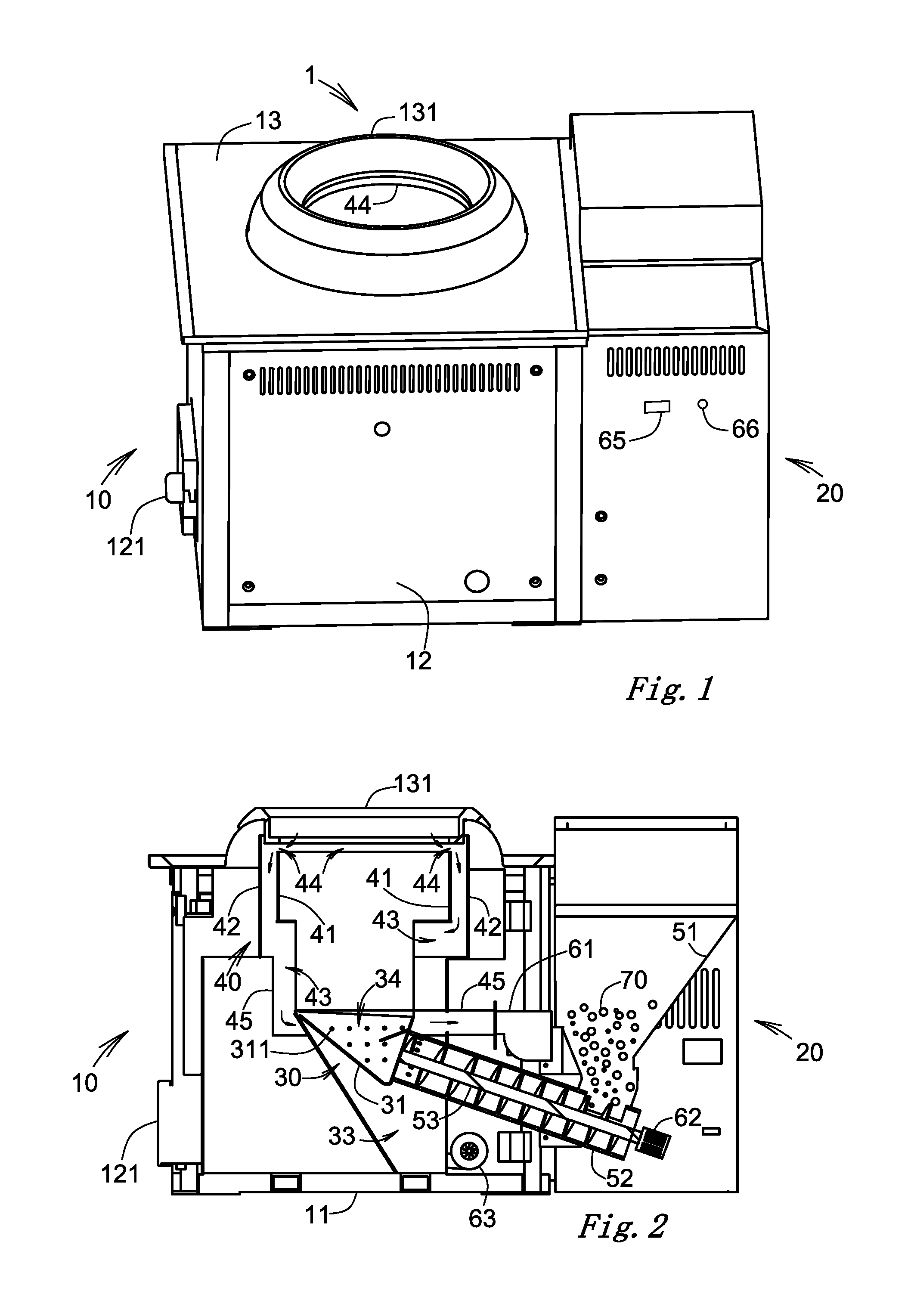

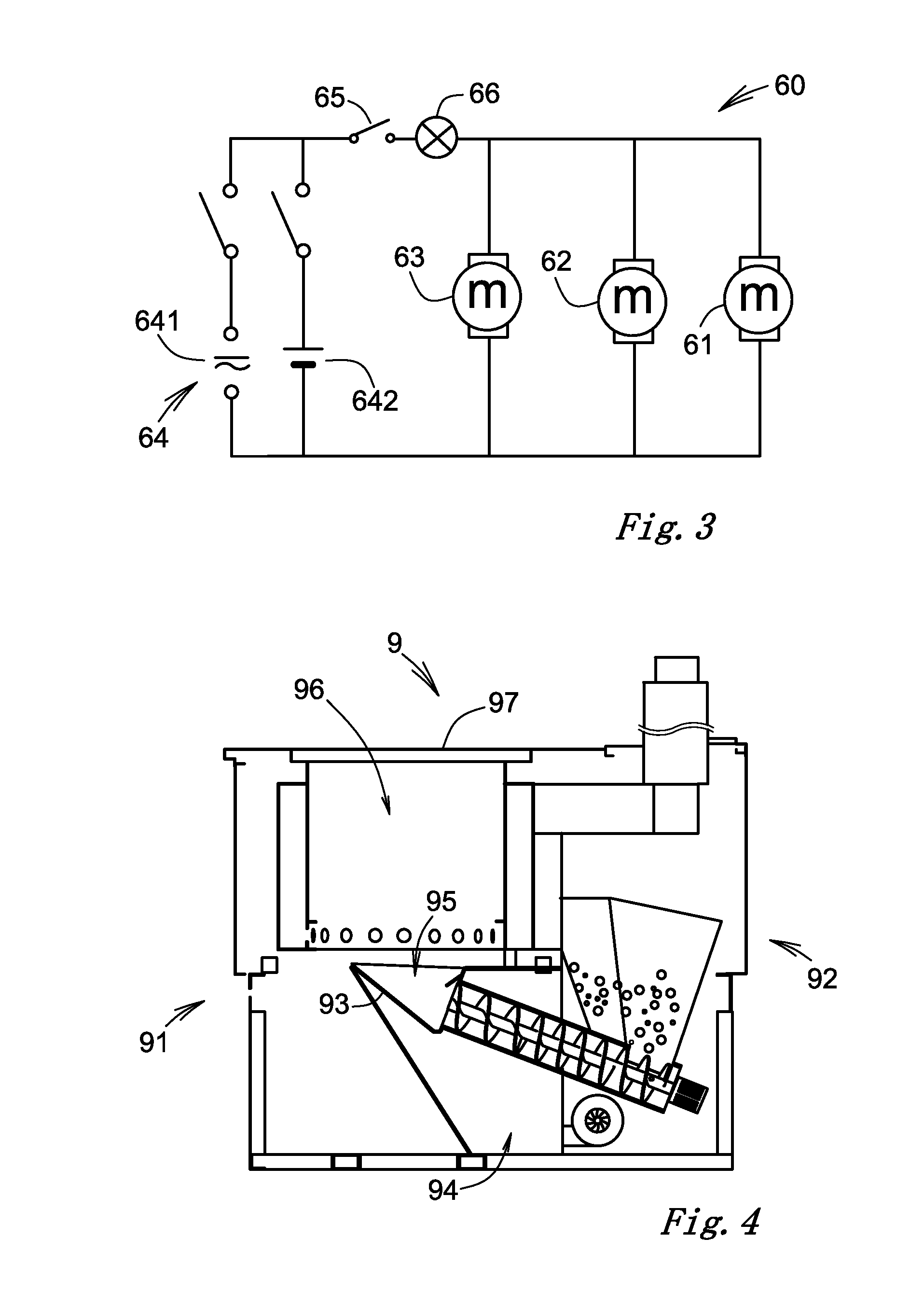

[0014]Shown in FIG. 1 is the preferred embodiment of the invention, an oven without dust rise. The oven has a body 1 which is able to be placed on the ground. The body 1 has a combustion cabinet 10 and an auxiliary equipment cabinet 20.

[0015]With reference to FIGS. 2 and 3, the combustion cabinet 10 has a bottom 11 which is able to be levelly placed on the ground, a side 12 extending upward from a peripheral of the bottom 11, and a top 13 in connection with an upper peripheral of the side 12 and opposite to the bottom 11. An oven-top 131 is defined in the top 13. A door 121 is provided in the side 12.

[0016]The combustion cabinet 10 has a burner 30 received therein. The burner 30 has a fire grate 31. An air supply zone 33 is defined beneath the fire grate 31 and burning zone 34 is defined above the fire grate 31. A plurality of vent-holes 311 are defined in the fire grate 31.

[0017]A dust removing device 40 is provided between the burner 30 and the oven-top 131. The dust removing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com