High-energy low-carbon synthetic fuel for kiln

A synthetic fuel and high-energy technology, applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems that synthetic fuel has not been reported, and achieve the effect of eliminating carbon dioxide residues, reducing costs and achieving remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

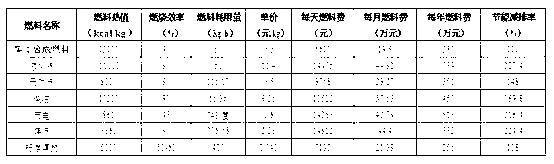

Image

Examples

Embodiment 1

[0020] The high-energy low-carbon synthetic fuel for kilns is composed of the following components in mass ratio:

[0021] Methanol 60%

[0022] Acetone 20%

[0023] water 5%

[0024] Catalyst 3%

[0025] Accelerator 5%

[0026] Emulsifier 7%;

[0027] Among them, the catalyst is styrene C 8 h 8 and xylene C 8 h 10 The mixture of any mass ratio; the combustion aid is carbon five C 5 h 12 ; The emulsifier is sodium hydroxide and isomerized ten alcohol polyoxyethylene ether C 2 h 4 A mixture of any mass ratio of O; after mixing the above-mentioned components evenly, a high-energy low-carbon synthetic fuel for kiln is obtained.

Embodiment 2

[0029] The high-energy low-carbon synthetic fuel for kilns is composed of the following components in mass ratio:

[0030] Ethanol 75%

[0031] Acetone 5%

[0032] water 8%

[0033] Catalyst 0.5%

[0034] Accelerator 6.5%

[0035] Emulsifier 5%;

[0036] Among them, the catalyst is cerium trioxide Ce 2 o 3 ; The combustion aid is hydrogen peroxide H 2 o 2 It is a mixture with any mass ratio of activated carbon; the emulsifier is calcium hydroxide; after mixing the above components evenly, a high-energy low-carbon synthetic fuel for kiln is obtained.

Embodiment 3

[0038] The high-energy low-carbon synthetic fuel for kilns is composed of the following components in mass ratio:

[0039] Ethanol 40%

[0040] Acetone 30%

[0041] water 8%

[0042] Catalyst 2%

[0043] Accelerator 10%

[0044] Emulsifier 10%;

[0045] Among them, the catalyst is styrene C 8 h 8 , Xylene C 8 h 10 and ferrocene FeC 10 h 10 The mixture with a mass ratio of 1:3:2; the combustion aid is carbon five C 5 h 12 , hydrogen peroxide H 2 o 2 A mixture of activated carbon and activated carbon in a mass ratio of 1:1:2; the emulsifier is sodium hydroxide, calcium hydroxide and isomerized decanol polyoxyethylene ether C 2 h 4 O is a mixture with a mass ratio of 1:1:1; after mixing the above-mentioned components evenly, a high-energy and low-carbon synthetic fuel for kilns can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com