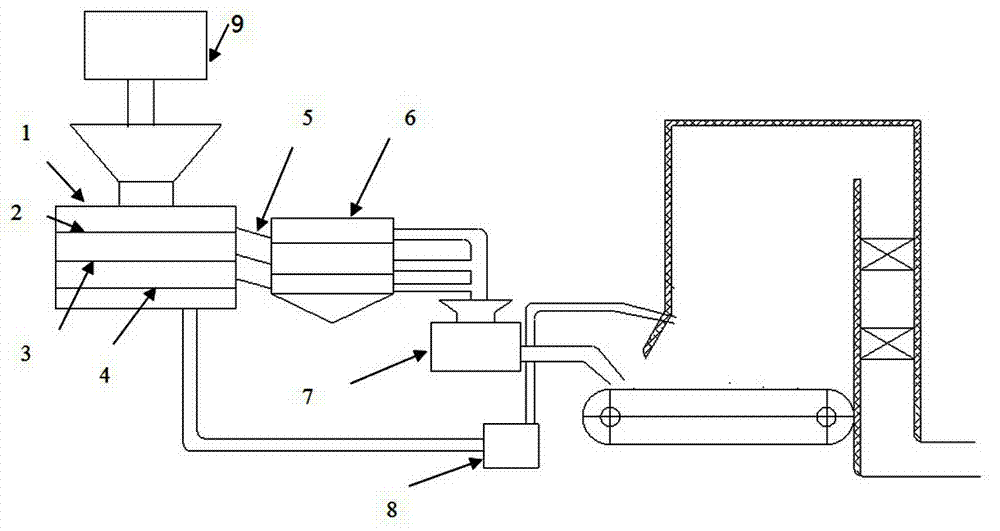

Online automatic classification device and classification method for fuel coal in composite combustion

An automatic grading and grading method technology, applied in the direction of combustion methods, combustion equipment, fuel supply, etc., can solve the problems of low thermal efficiency, insufficient use of fuel coal, high emissions of smoke and nitrogen oxides, and achieve full and efficient combustion, reduce Work load, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] A fuel coal online automatic grading device in composite combustion, the structure is the same as that of embodiment 1; when burning, the coal lumps with particle diameters of 3-6mm, 6-25mm, and 25-40mm are respectively divided into 15 according to the feeding amount: The ratio of 85:10 is sent to the coal feeder, and the others are the same as in Embodiment 1.

Embodiment 3

[0040] A fuel coal online automatic grading device in composite combustion, the structure is the same as that of embodiment 1; when burning, the coal lumps with particle diameters of 3-6mm, 6-25mm, and 25-40mm are respectively divided into 20 according to the feeding amount: The ratio of 65:15 is sent to the coal feeder, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com