Efficient in-situ fuel gas thermal desorption heating device and method

A technology of additional heat and gas, applied in the field of high-efficiency in-situ gas heat desorption and additional heat devices, can solve the problems of increased heat loss of combustion exhaust, increased gas consumption, and low energy utilization rate, so as to realize heat energy and improve progress The effect of reducing gas temperature and reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

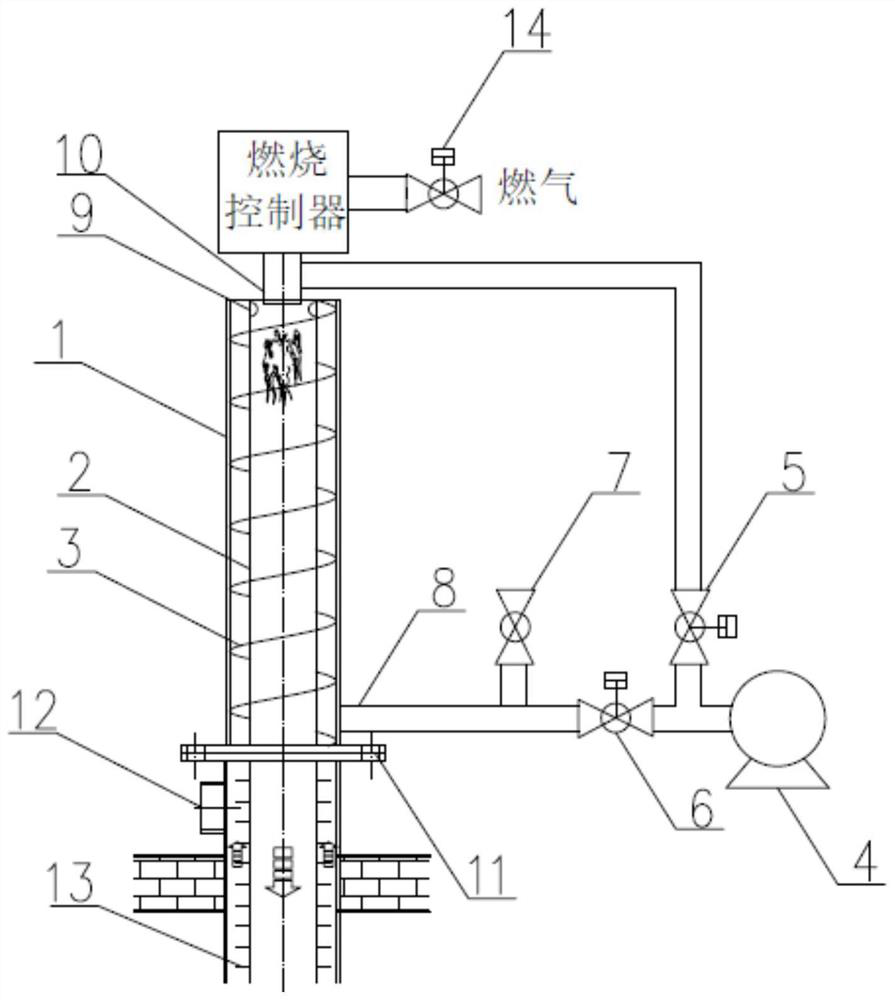

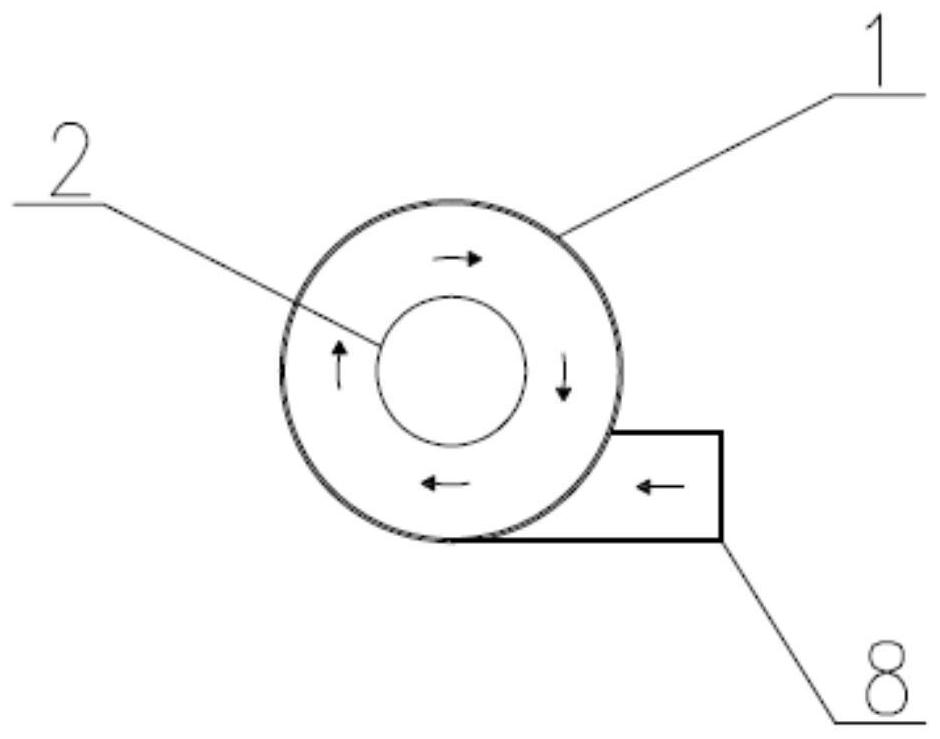

[0034] refer to figure 1 , figure 2 , This embodiment case 1 discloses a high-efficiency in-situ gas thermal desorption additional heat device, including a combustion controller, a combustion well, a blower 4, and a heating well 11. The combustion controller is arranged on the upper part of the combustion well, and the combustion controller is provided with a gas interface and a gas regulating valve 14; the lower part is connected with a gas / primary air mixing pipe 10, and the lower part of the mixing pipe is provided with a plurality of distribution holes, and extends into the upper part of the inner pipe of the combustion well; The combustion well is a cylinder composed of inner and outer tubes arranged concentrically. A spiral diversion groove 3 is arranged between the inner tube 2 and the outer tube 1 of the combustion well, and a plurality of secondary inlets are arranged on the inner tube wall on the upper part of the spiral diversion groove at the top. The air distrib...

Embodiment example 2

[0039] refer to figure 1 , figure 2 , the structure principle of this implementation case is basically the same as that of implementation case 1, the difference is: in this implementation case, the in-situ gas thermal desorption additional heat device is used as a waste gas reburning well for the purification treatment of waste gas. Close the secondary air regulating valve 6, open the primary air regulating valve 5, and turn on the blower. The extraction tail gas from the heat removal additional heat site is first subjected to condensation and separation treatment, and then screwed into the cavity between the inner and outer tubes of the combustion well through the waste gas interface valve 7, and exchanges heat with the high-temperature waste gas generated by the combustion in countercurrent. It reaches 200~300℃, and enters the combustion chamber through the secondary air intake distribution hole. The high-temperature exhaust gas and the high-speed spiral make the exhaust g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com