Automated bio-fuel burning multi-purpose furnace

A biofuel, multi-purpose furnace technology, applied in the field of combustion furnaces, can solve the problems of ineffective utilization of biomass fuels, causing fires, safety hazards, etc., and achieve the effects of saving non-renewable resources, reducing emissions, and effectively utilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

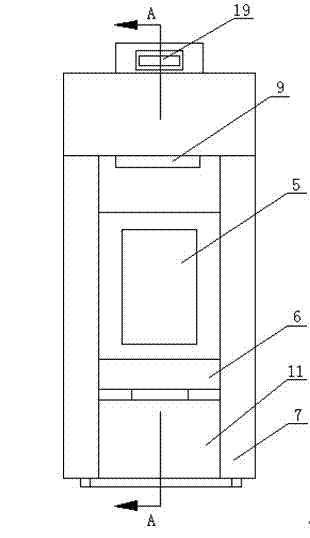

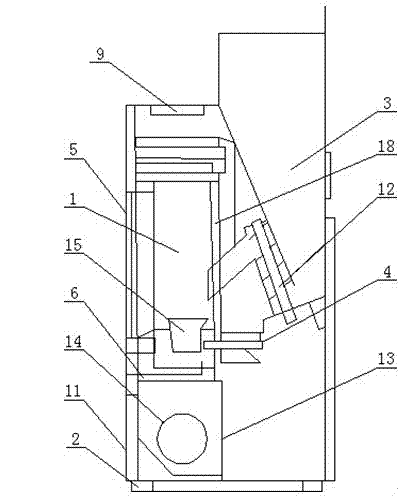

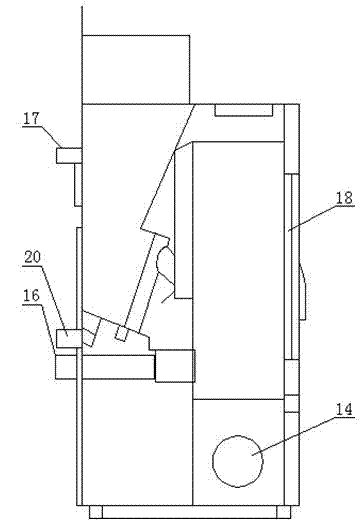

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] like Figure 1-Figure 4 As shown, an automatic biofuel combustion multi-purpose furnace includes a furnace body. The furnace body includes a combustion furnace 1, a fuel hopper 3, a feeding device and an automatic control device 13. The fuel hopper 3 is located above the side of the combustion furnace 1, and the combustion furnace 1 A feed pipe is arranged obliquely, and a combustion pool 15 is arranged in the combustion furnace 1. The lower port of the feed pipe is located above the combustion pool 15, and the feeding device is arranged between the upper port of the feed pipe and the fuel hopper 3. The furnace body An automatic igniter 4 is provided, the front end of the automatic igniter 4 is in contact with the fuel bucket 3, the side wall of the combustion furnace 1 is provided with a water heating cavity 18, and the combustion furnace 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com