Spiral supercharged fuel oil centrifuge for vehicle

A technology of screw supercharger and centrifuge, applied in non-displacement pumps, non-variable volume pumps, machines/engines, etc., can solve the problems of insufficient oil supply, oil suction resistance, long oil suction section of the oil pump, etc., and achieve high combustion efficiency. Fully, improve the combustion efficiency, improve the effect of fuel density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

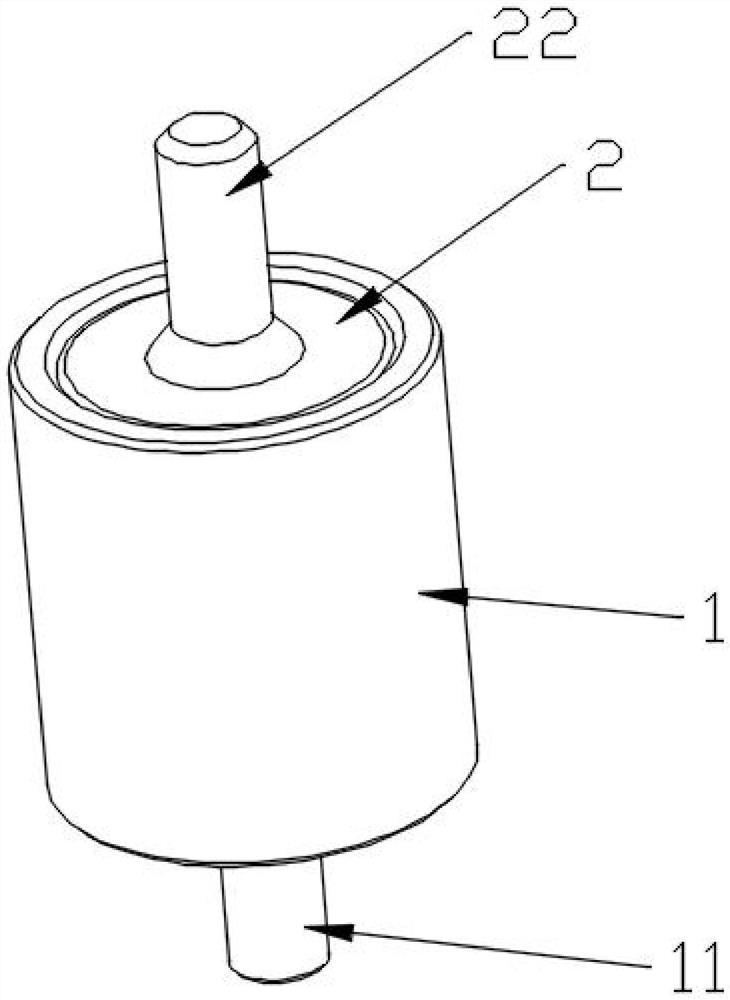

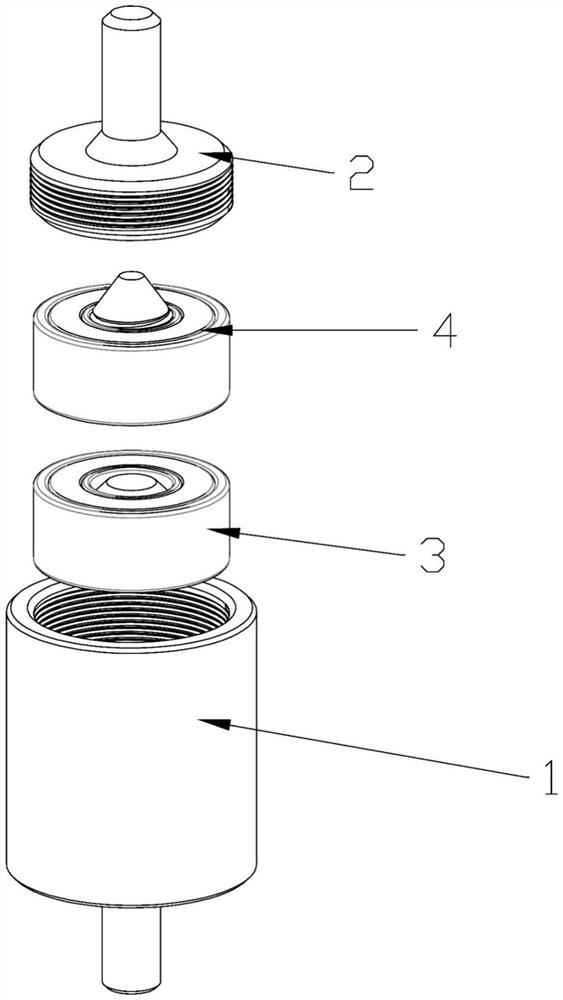

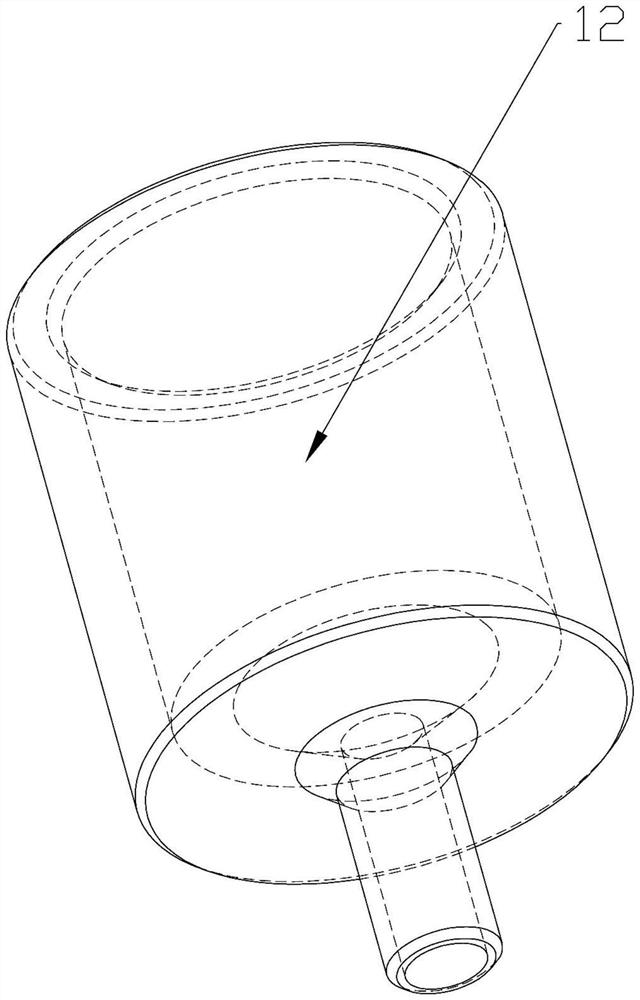

[0038] Example 1, such as Figure 1 to Figure 13 As shown, a spiral supercharged vehicle fuel centrifuge is provided with a shaft sleeve 1, the upper end of the shaft sleeve 1 is provided with a sleeve head 2, the lower end of the shaft sleeve 1 is provided with an oil inlet pipe 11, and the upper end of the sleeve head 2 is provided with an oil outlet pipe 22. 1 is provided with a circular hole groove 12, and the circular hole groove 12 is provided with an oil inlet bearing assembly 3 and an oil outlet bearing assembly 4. The assembly 4 is provided with a bearing II41, and a threaded core II42 is arranged inside the bearing II41.

[0039] The threaded core I32 is interference fit with the inner ring of the bearing I31, and the threaded core I32 rotates in the bearing I31; the threaded core II42 interferes with the inner ring of the bearing II41, and the threaded core II42 rotates with the bearing II41.

[0040] A spiral groove 5 is provided in the middle of the outer surface...

Embodiment 2

[0048] Such as Figure 14 to Figure 18 As shown, this embodiment is basically the same as Embodiment 1, except that the upper ends of the threaded core II 42 and the threaded core I 32 are changed to a helical blade-shaped platform 44, and the lower ends of the threaded core I 32 and the threaded core II 42 are cut flat.

[0049] A partition 8 is provided between the oil inlet bearing assembly 3 and the oil outlet bearing assembly 4 , and a chamfered circular groove 81 is provided in the middle of the upper and lower sides of the partition 8 .

[0050] The function of the spacer 8 is to divide the circular hole 12 in the shaft sleeve 1 into two chambers, so that the threaded core I32 and the threaded core II42 are respectively located above and below the spacer 8, and the threaded core I32 and the threaded core II42 are in the When rotating at a high speed, they will not interfere with each other, preventing the threaded core I32 from conflicting with the threaded core II42. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com