Vertical back burning single twist machine

A back-firing single twister and vertical technology, applied in the field of twister, can solve the problems of signal core wire destroying the crystal structure of conductor surface, affecting the transmission loss and delay of the cabled cable, difficult to relocate and install, etc. Collect information and data feedback to save, improve the efficiency of stranding, and facilitate the effect of relocation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

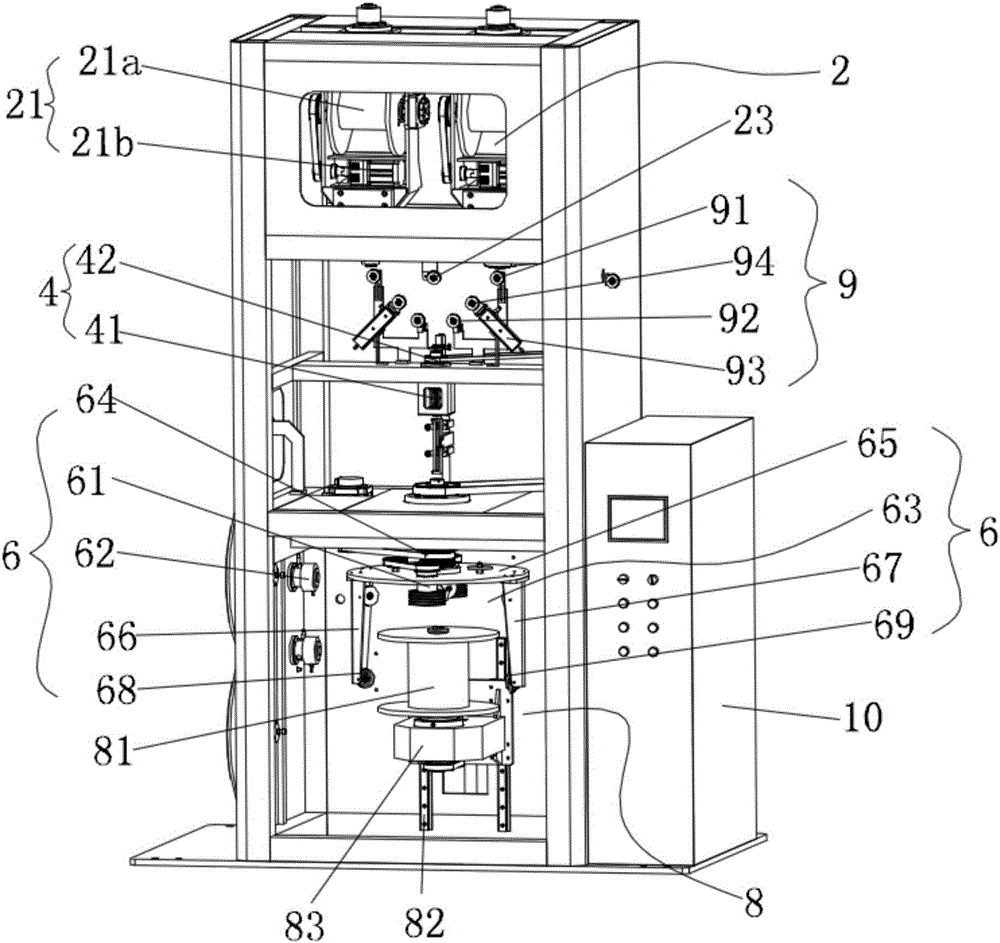

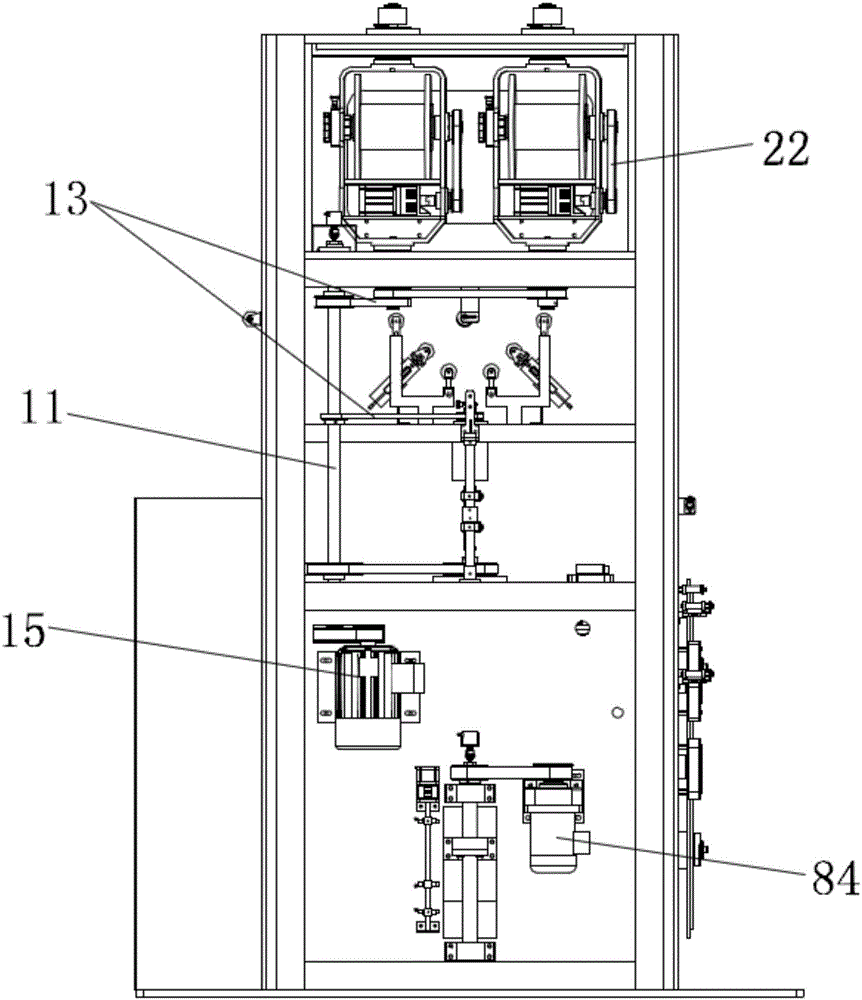

[0035] Such as figure 1 , 2 As shown, this embodiment discloses a vertical back-burning single twisting machine, which is used to twist and wrap multiple strands of core wires into one cable. The back-burning and untwisting device 2, the wire device 9, the pre-twisted wire device 4, the lead-out device 6 and the wire-receiving device 8 in the cabinet, as well as the electronic control device 10 that controls the work of each mechanism, and the electronic control device 10 is set next to it On the side of the vertical cabinet machine, the vertical backfiring untwisting device 2 is used to untwist the signal core wires along with the twisting production line, and the wire device 9 is used to unwind the core wires (including signal core wires, grounding wires) core wire) into the pre-twisted wire device 4, the pre-twisted wire device 4 is used to twist the multi-strand core wire into a primary twisted wire, and the lead wire device 6 is used to twist the primary twisted wire and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com