Energy-saving environment-friendly type back burning boiler

An energy-saving and environmentally friendly boiler technology, applied in the field of boilers, can solve the problems of automatic discharge of massive waste slag into the furnace ash bin, low heating efficiency, insufficient combustion, etc., and achieve the effect of accelerating air flow speed, sufficient combustion, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

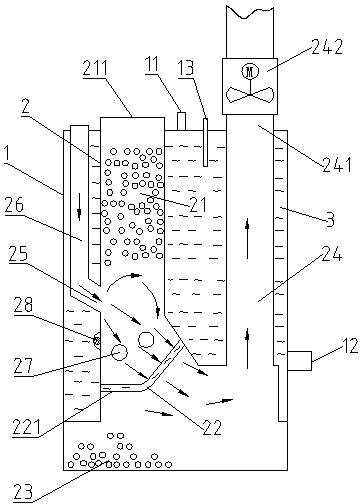

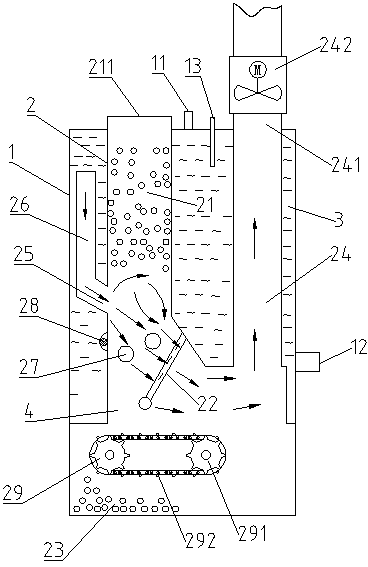

[0025] Such as figure 1 As shown, the energy-saving and environment-friendly reverse combustion boiler of the first embodiment of the present invention is composed of a pot body 1 and a furnace body 2, the pot body 1 is arranged outside the furnace body 2, and the cavity 3 formed between them is used for Hold water. A water inlet 11 is arranged on the top of the pot body 1 , a water outlet 12 is arranged below its side wall, and a water temperature detection element 13 is arranged on the top thereof, and the water temperature detection element 13 is used for detecting the water temperature in the pot body 1 .

[0026] Fuel bin 21 is arranged on the top of body of heater 2, is provided with fire grate 22 at the bottom of fuel bin 21, is provided with furnace ash bin 23 below fire grate 22, communicates with fuel bin 21 bottom and is provided with exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com