Vertical aerobic fermentation bin

An aerobic fermentation and vertical technology, which is applied in the direction of climate change adaptation and organic fertilizers, can solve the problems of large ventilation resistance, easy compaction of materials, and large resistance, and achieve small ventilation resistance, small discharge resistance, and oxygen supply. sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

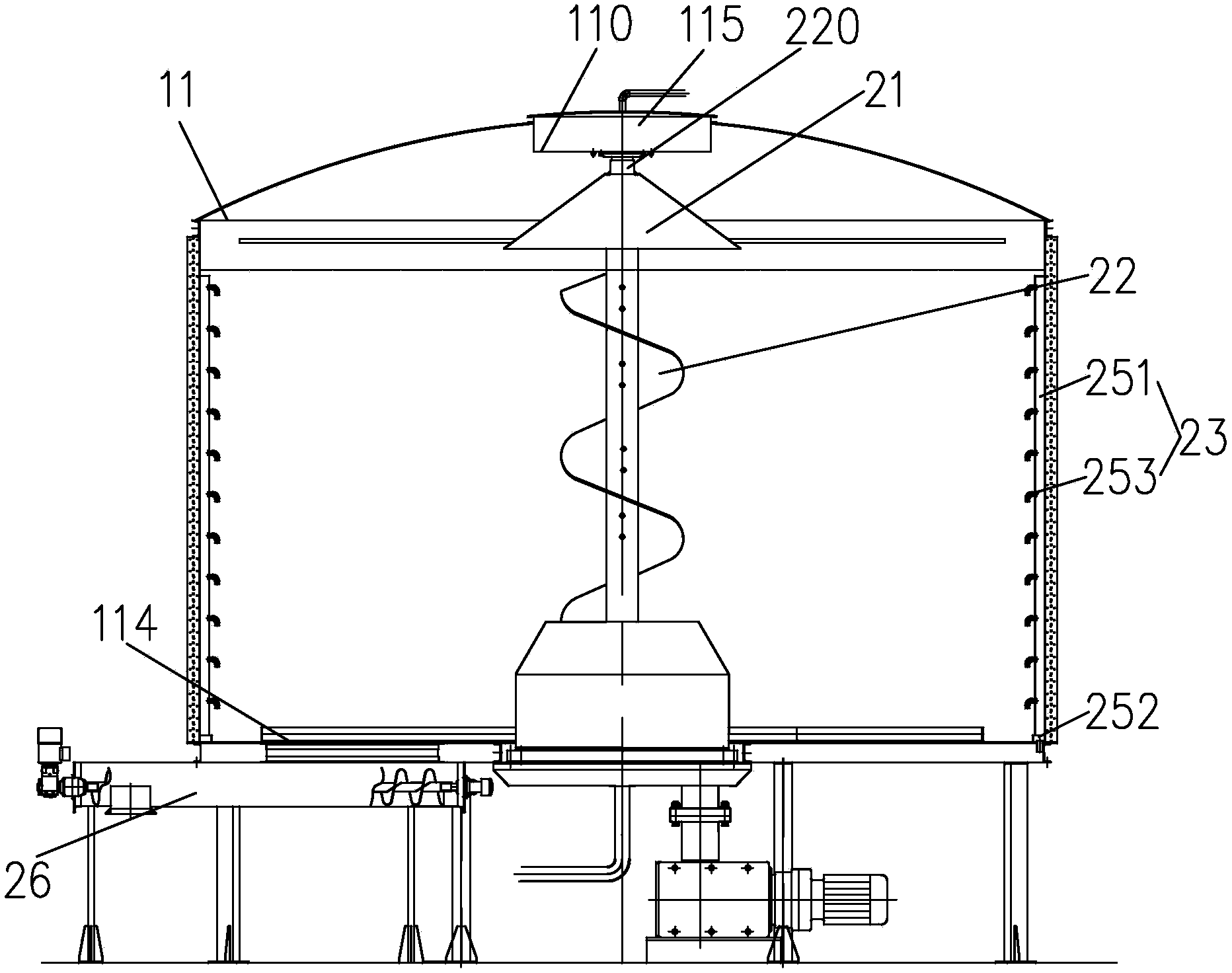

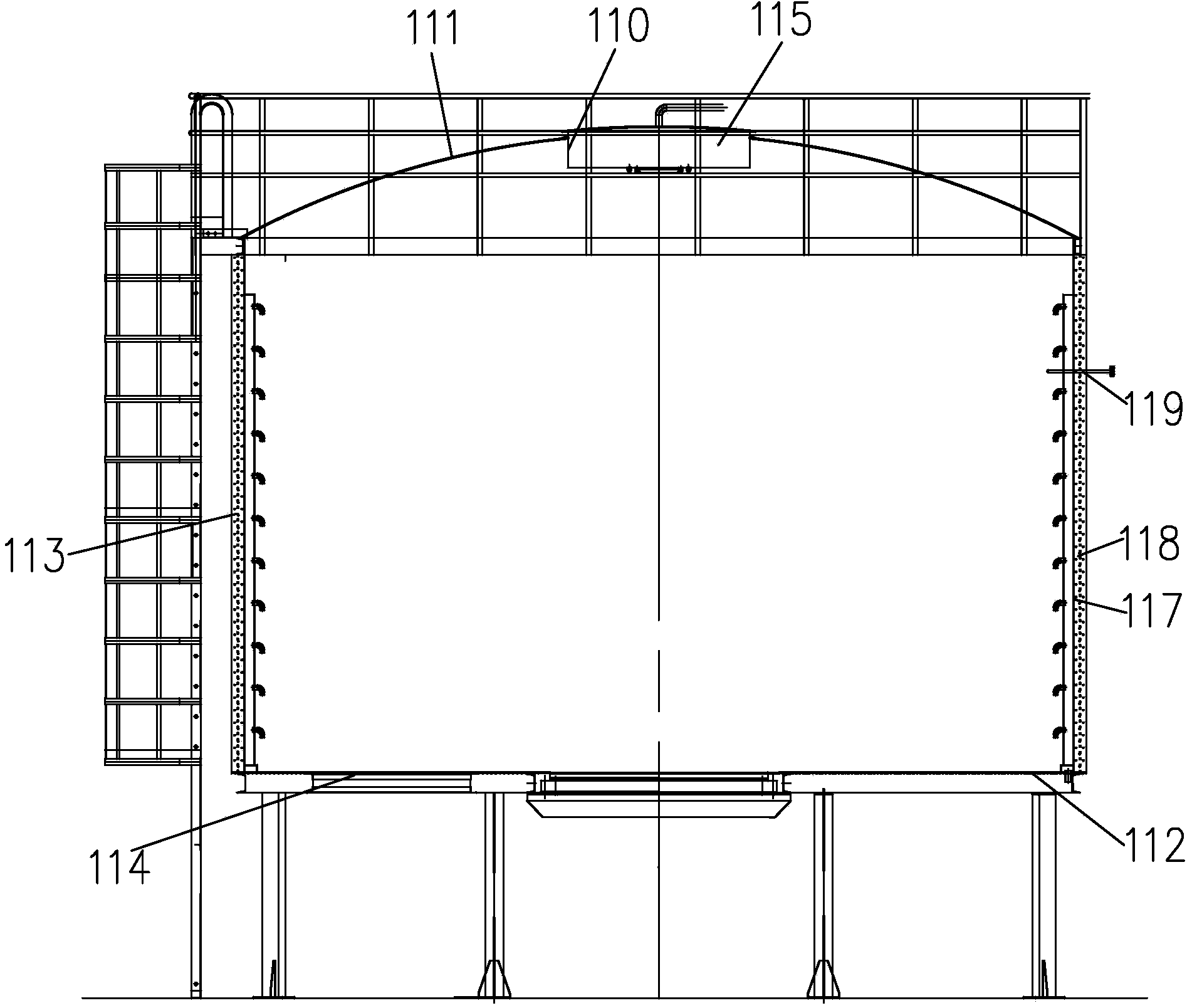

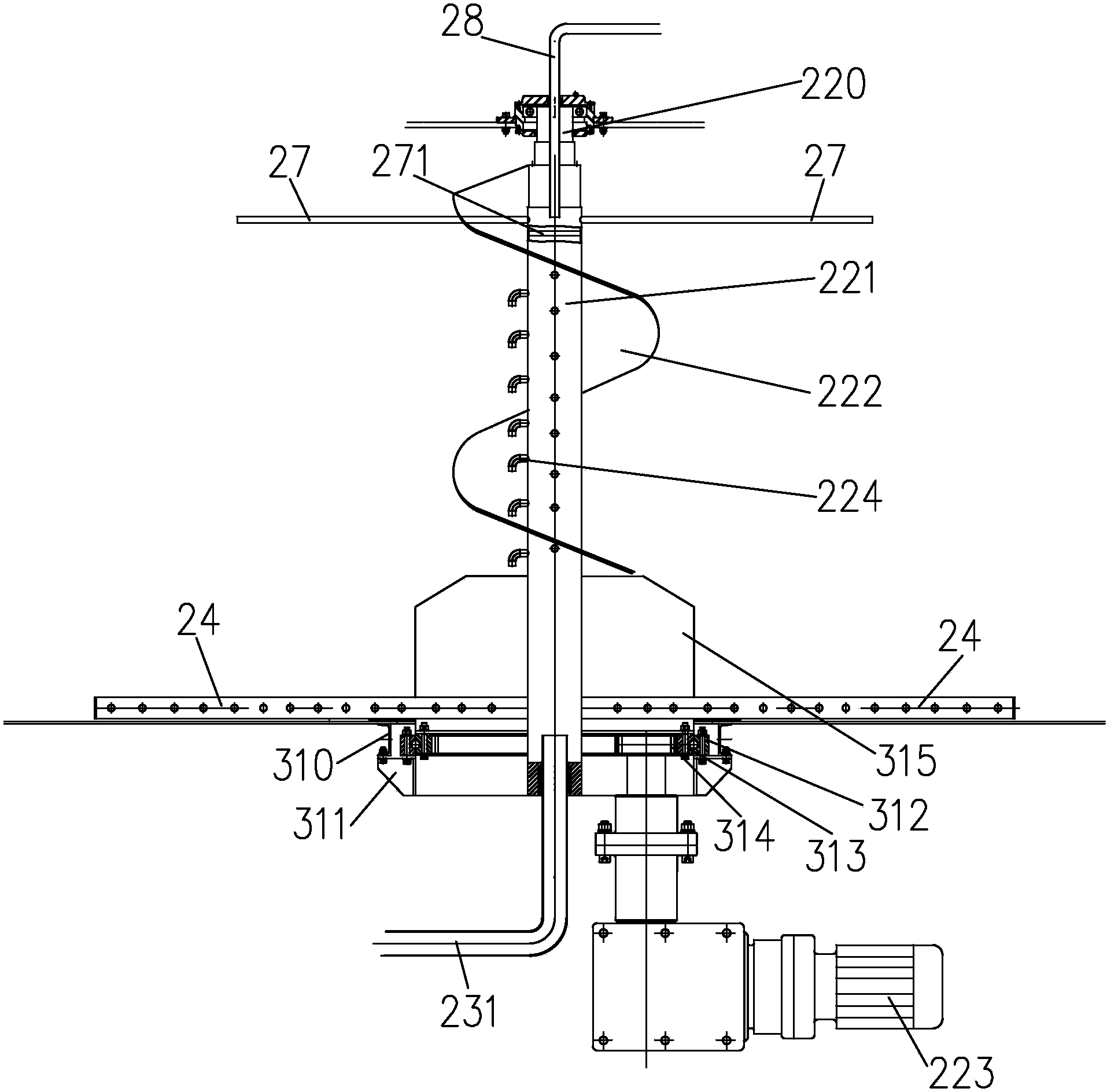

[0021] Such as figure 1 , 2 As shown, the vertical aerobic fermentation chamber of the present invention comprises a tank body 11, a distributor 21 and a ventilation device 23 are arranged in the tank body 11, a ladder and a guardrail are provided on the outer wall of the tank body 11, and the tank body 11 includes a tank top 111, a tank Bottom 112, side wall 113, tank bottom 112 is provided with discharge port 114, tank top 111 is provided with feed port 115, and tank body 11 is also provided with stirring, turning device 22, as image 3 As shown, the stirring and turning device 22 includes a central shaft 221, a screw 222 fixed on the central shaft 221, a driving motor 223 and a transmission device, the screw 222 is a double-ended screw, the tank top 111 is arched, and the tank top 111 is welded around There are edge-wrapped channel steels, the top ring beam 110 is welded at the center of the tank top 111, and edge-wrapped channel steels are welded around the tank bottom 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com