Group standing robot online automatic back-burning device and back-burning operation method

A technology of robots and small groups, which is applied to heat treatment equipment, manipulators, furnaces, etc., can solve problems such as low efficiency and unsafety, and achieve the effects of shortening time, improving efficiency, and moving positions accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

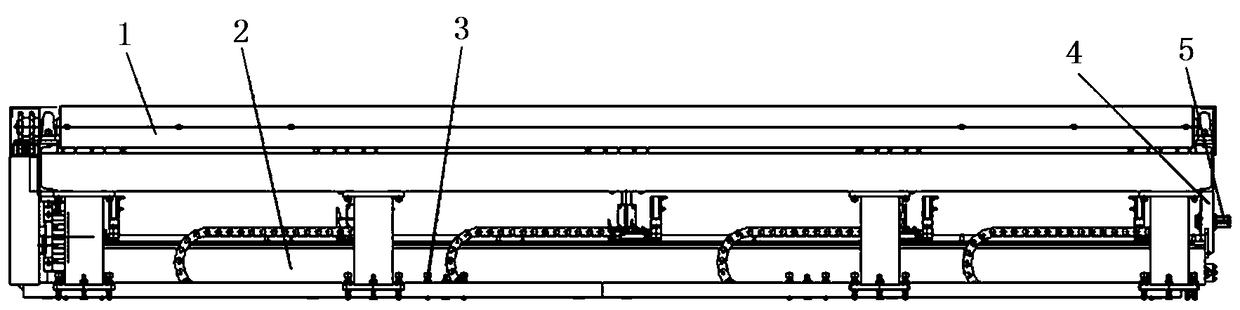

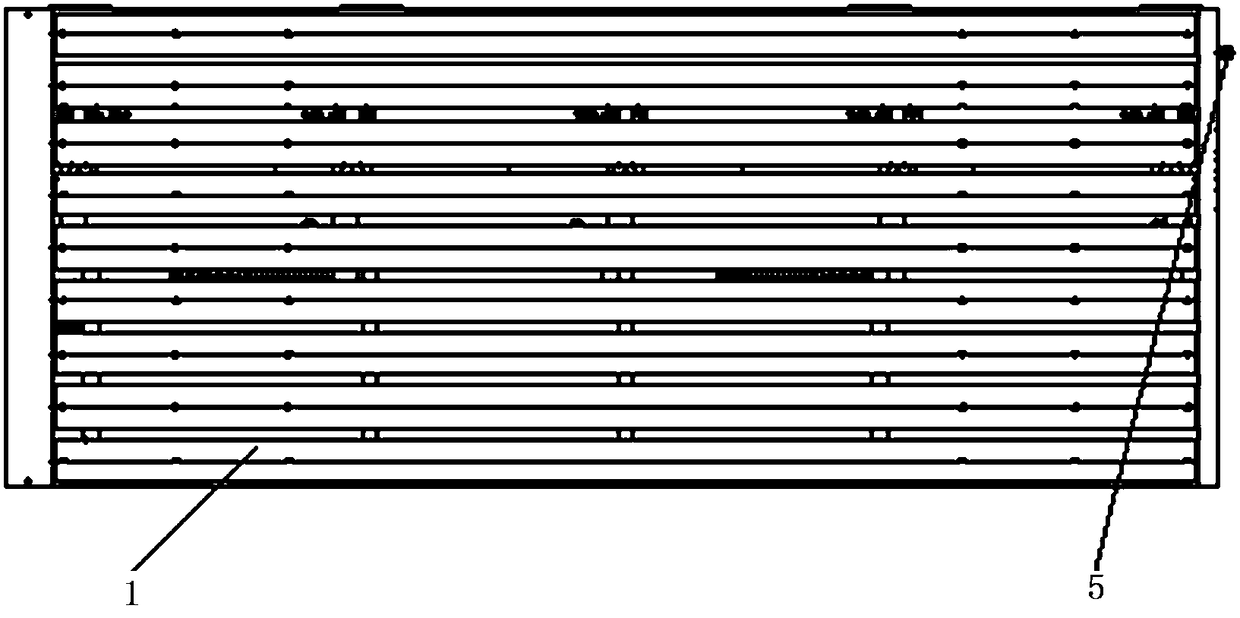

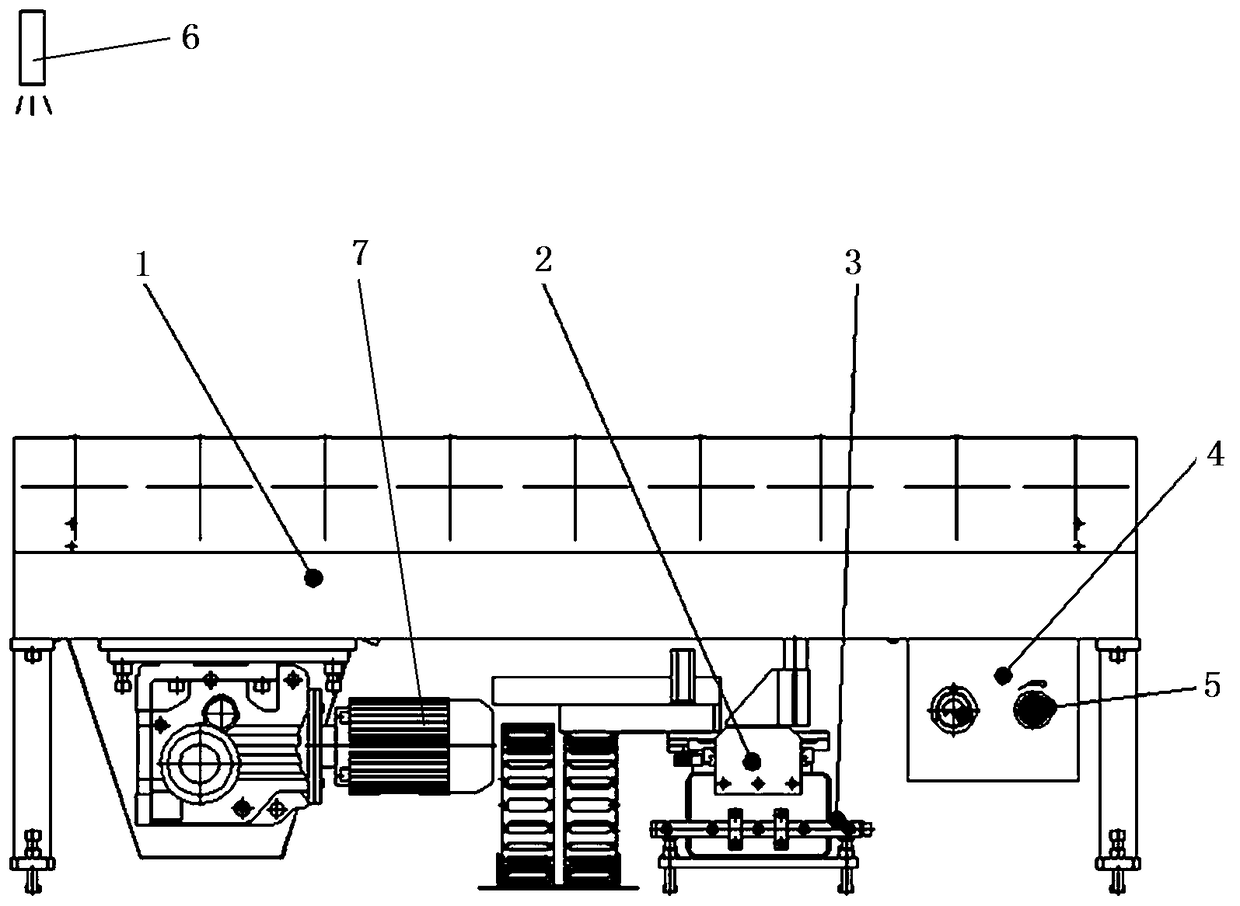

[0051] see Figure 1 to Figure 3 , a group of stand-up robot online automatic back-burning equipment, including a transmission roller mechanism, a back-burning flame mechanism 2, an air source box 4, a shunt row 3 and a positioning sensor 6; the transmission roller mechanism includes a transmission roller mechanism 1 and a gear motor 7 , the conveying roller table 1 is arranged horizontally, and the conveying roller table 1 is controlled by a reduction motor 7 to transmit workpieces, and a plurality of back-burning flame mechanisms 2 are arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com