Waste oil smelting exhaust gas back-burning device

A waste gas and back-burning tube technology, which is applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of easy explosion and air pollution, and achieve the effect of saving energy and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

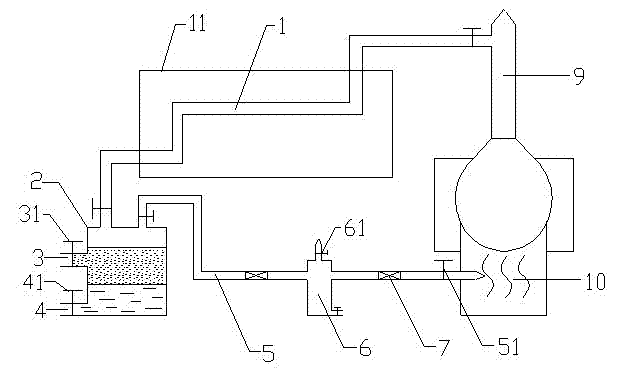

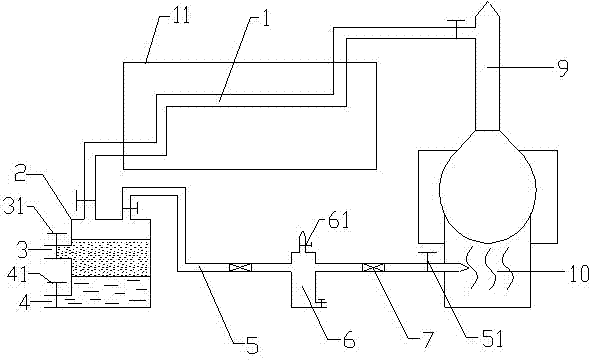

[0017] Embodiment 1, the waste oil smelting waste gas back-burning device of the present invention includes a separation cabinet 2 connected to the condensing oil outlet pipe 1, an oil outlet 3 and a water outlet 4 are arranged on the separation cabinet, and oil outlets and water outlets are respectively provided with oil outlet valves 31 and the water outlet valve 41 also include a waste gas back-burning pipe 5, one end of the waste gas back-burning pipe communicates with the top of the separation cabinet, and the other end communicates with the hearth of the oil refining furnace, and the waste gas back-burning pipe is provided with a waste gas control valve 51 near the end of the oil refining furnace. During oil refining, high-temperature oil and gas come out of the fractionating tower 9 and enter the condensate oil outlet pipe 1. The middle section of the condensate oil outlet pipe 1 is located in the cooling pool 11. After condensation, semi-finished oil is generated and ent...

Embodiment 2

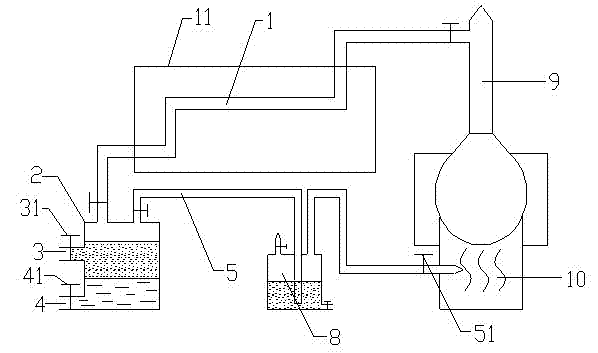

[0020] Embodiment 2. The difference between this embodiment and Embodiment 1 lies in the different designs of the anti-tempering device. In this embodiment, the anti-tempering device includes a flame-retardant cabinet 8, which contains water and waste gas back-burning pipes One end of the air intake is arranged under the water surface. The non-condensable gas enters the flame-retardant cabinet through the water surface of the flame-retardant cabinet 8 filled with water, and then enters the furnace, and the tempering phenomenon occurs in time. When the tempering reaches the flame-retardant cabinet 8, due to the barrier effect of the water in the flame-retardant cabinet , to prevent the tempering from continuing to spread to the end of the separation cabinet, so it will not lead to safety accidents.

[0021] As a further improvement to the above two embodiments, a pressure relief valve 61 is also provided on the top of the secondary separation cabinet 6 . When the refining furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com