High-temp.-resistant boule back-burning fire grate

A fire grate and corundum technology, applied in the field of anti-burning fire grate, can solve the problems of low temperature of boiler furnace and furnace cellar, large maintenance of water pipe grate, easy environmental pollution, etc., so as to increase the temperature of furnace cellar and reduce maintenance workload and maintenance costs, the effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

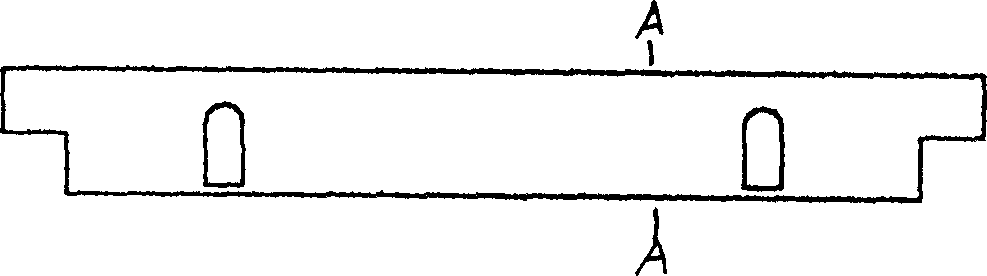

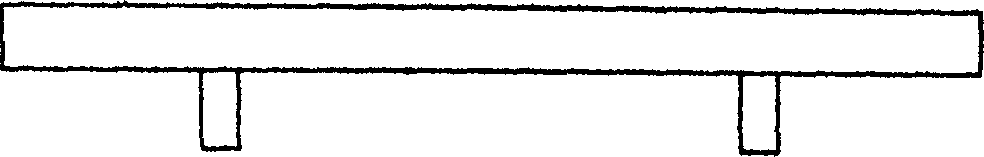

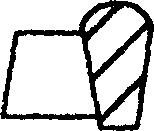

[0022] refer to figure 1 , figure 2 , image 3 As shown, the high-temperature-resistant corundum grate with a single solid structure of the present invention can be made of corundum powder-based refractory materials, and can be made into multiple single blocks, multiple solids, grid-shaped assemblies, and grate-shaped overall structures. The anti-fire grate. The temperature of the backburning grate can reach 1,000 to 1,800 degrees Celsius when the boiler is running, generating strong radiant heat, so that the unburned black smoke and other combustibles in the backburning coal seam are radiated heat when they pass through the backburning grate. Burn it to achieve the purpose of high efficiency, environmental protection and energy saving.

[0023] refer to Figure 4 ,Figure 5, Figure 6 Shown is the monomer double-row entity structure of the present invention.

[0024] See Figure 7, Figure 8 , Figure 9 Shown is the monomer multi-row entity structure of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com