Non-penetration laser welding apparatus and non-penetration laser welding method

A laser welding, laser welding head technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of ineffective prevention and adjustment, no development, high flexibility, and achieve strong adaptability and deep penetration , the effect of strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

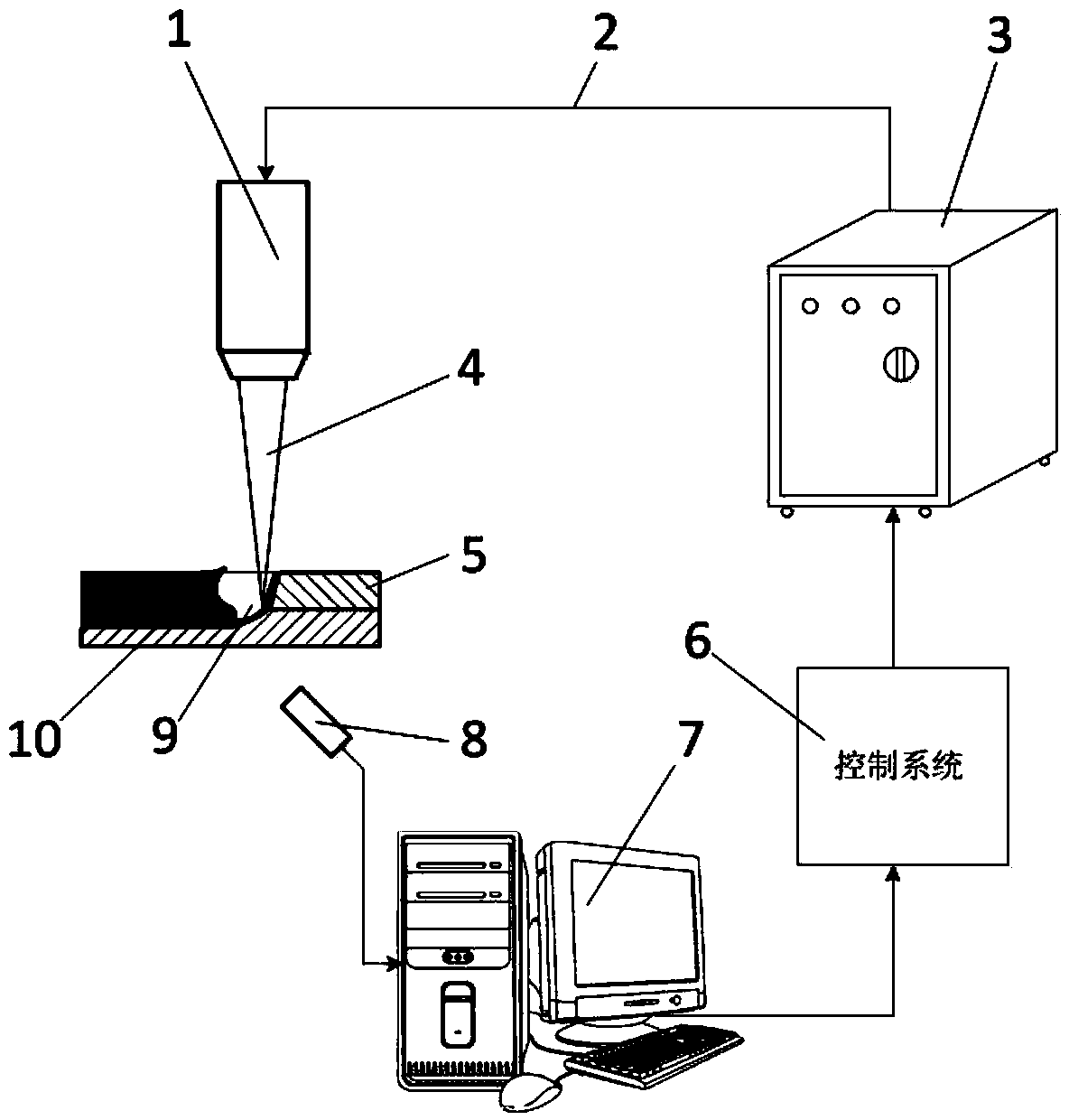

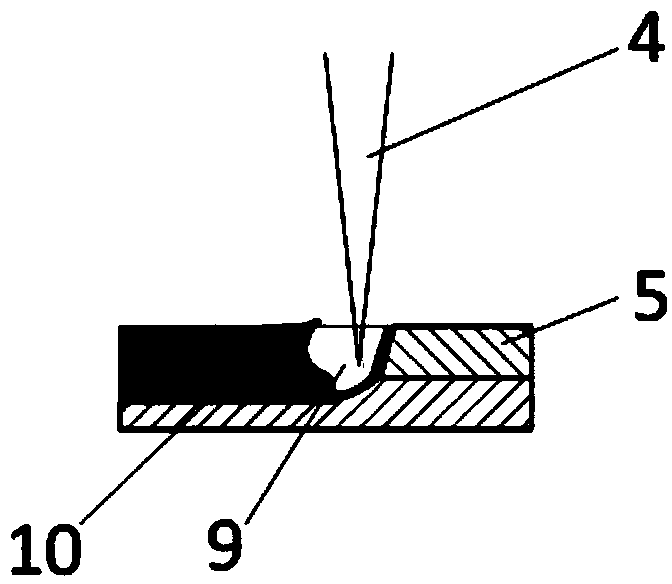

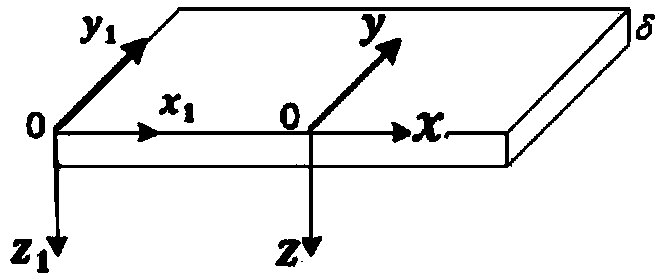

[0041] The following will be combined with the attached Figure 1-4 Specific embodiments of the present invention will be described in detail.

[0042] like figure 1 As shown, a non-penetrating laser welding equipment includes: a laser welding head 1, a transmission fiber 2, a laser 3, a feedback control system 6, a computer 7, and an infrared temperature acquisition system 8, which is characterized in that: the laser output by the laser 3, Conducted to the laser welding head 1 through the optical fiber 2, the laser beam 4 focused by the focusing lens inside the welding head acts on the surface of the welding material 5 to weld the material, and the infrared temperature acquisition system 8 captures the temperature of the back of the weld seam online during the welding process. And the acquired information is transmitted to the computer 7 in real time, and the computer 7 analyzes and processes the received information to obtain the welding penetration situation of the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com