Shipbuilding track-free back burning machine

A technology of back burner and rail, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of changing the draft of the ship, affecting the performance of the ship, and the long working cycle of pyrotechnics correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

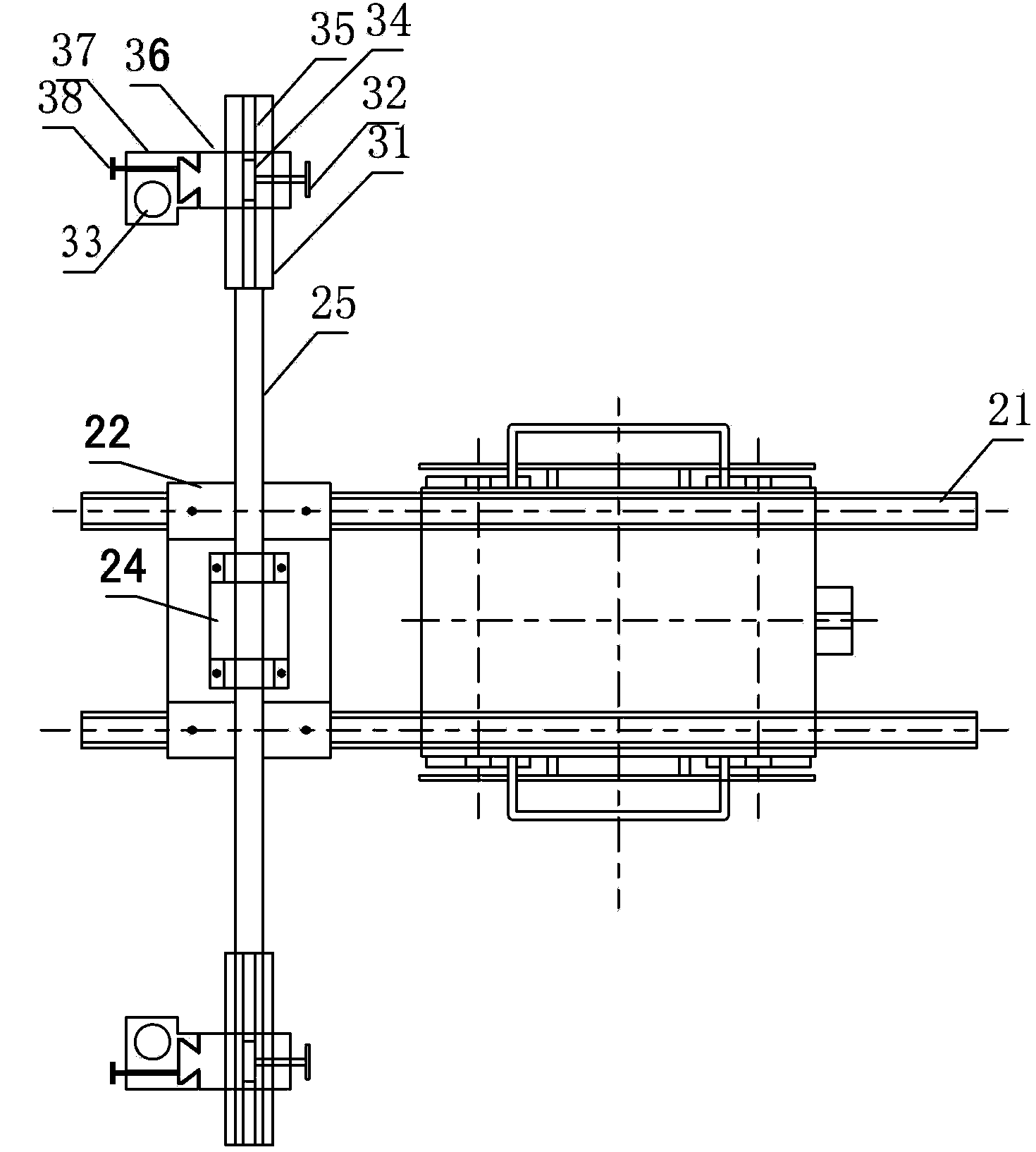

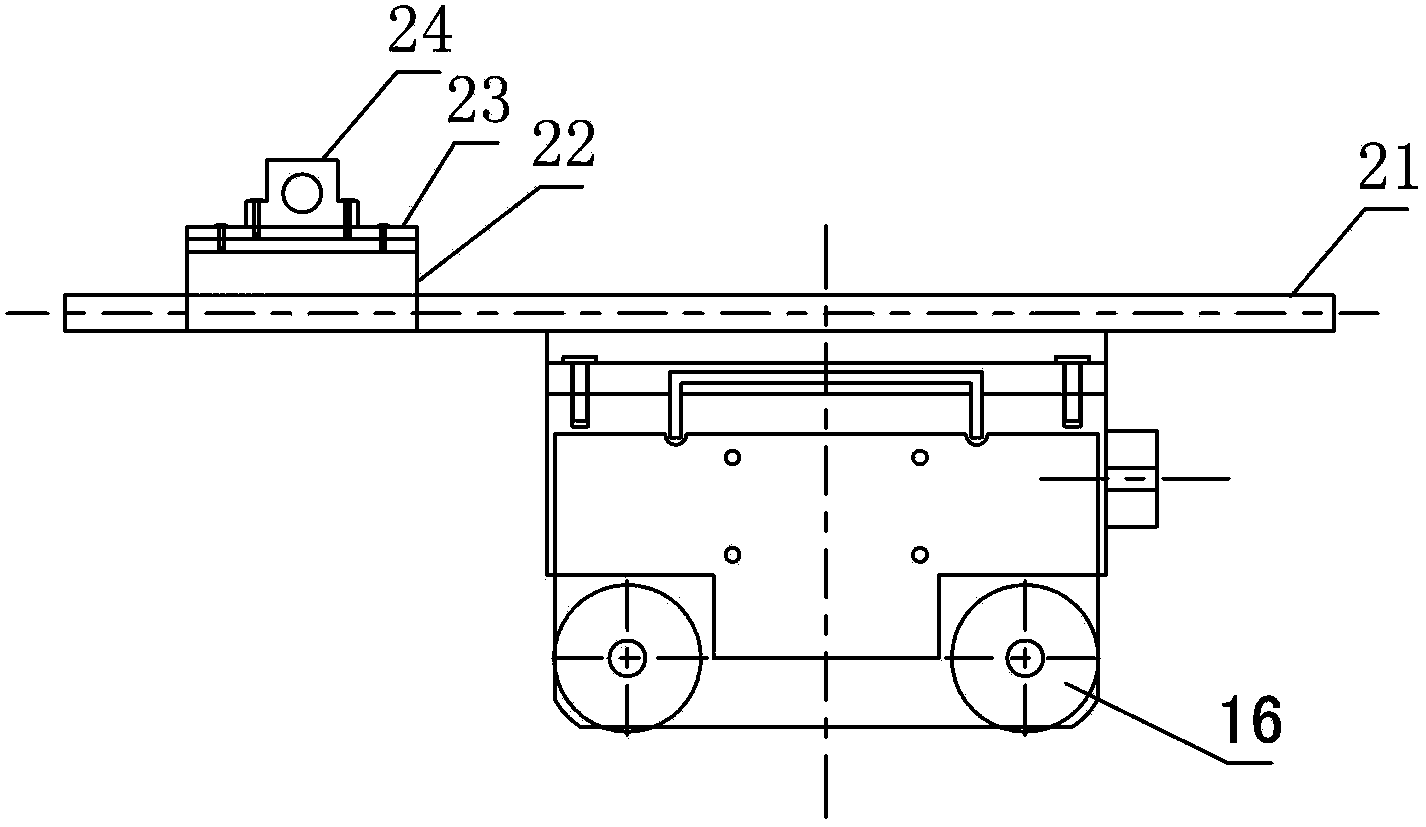

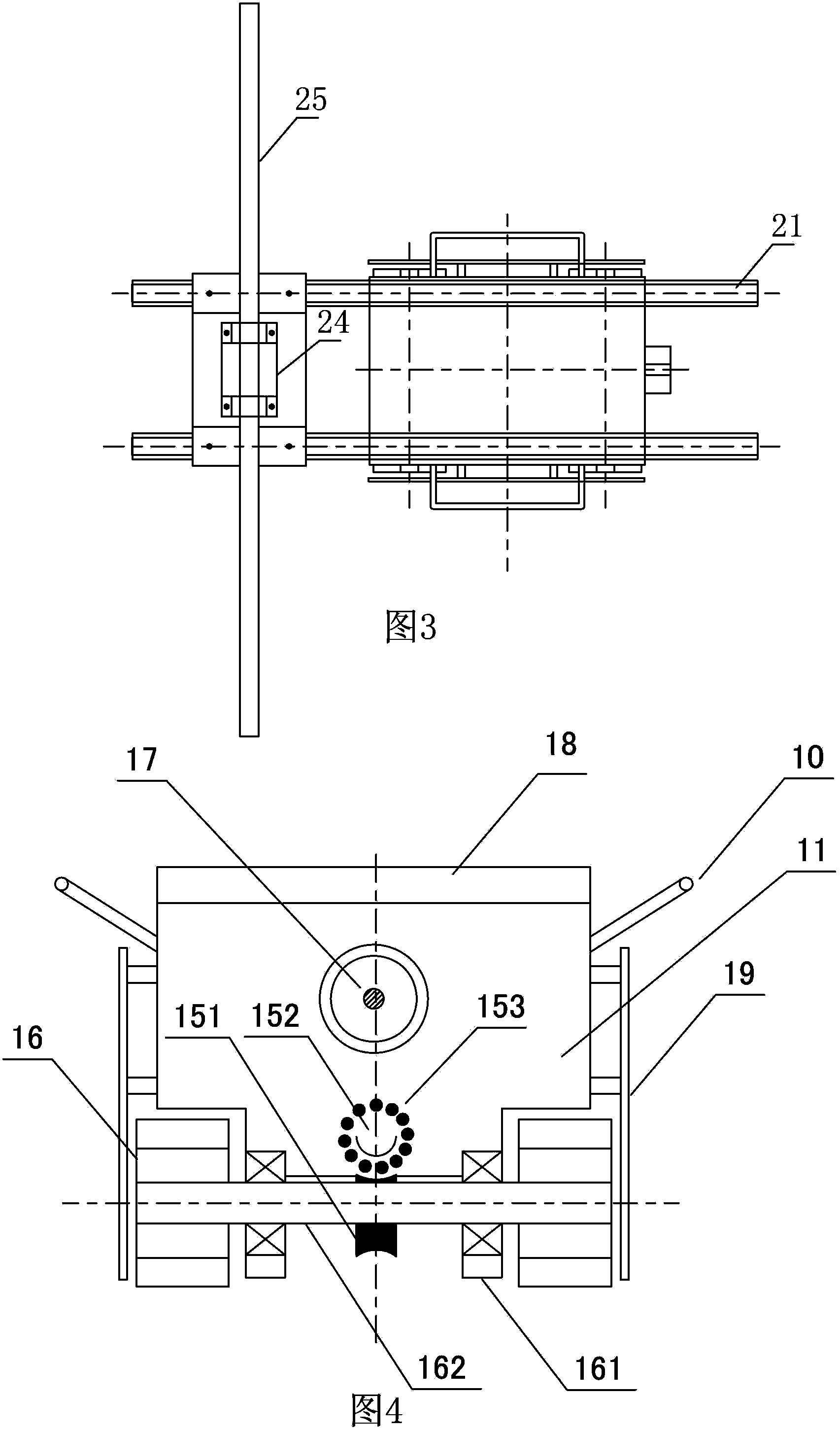

[0035] Such as Figure 1-3 As shown, the trackless back burning machine for ship construction of the present invention includes a main engine, a back burning torch adjustment unit, an integrated gas and electrical control unit. Wherein, mainly comprise the body 11 that the bottom is provided with permanent magnet driving wheel 16, the motor and the transmission mechanism that drive described driving wheel 16 in the body 11, and the oven torch 33 that utilizes pipeline to connect gas source fixed on the body 11. By setting the permanent magnet drive wheel 16, the main engine can walk straight on the steel plate at 0 degrees (above the steel plate) or 180 degrees (below the steel plate), and at the same time, during the walking process, the internal stress in the welding process of ship steel can be eliminated by the torch , eliminating the need for manual operation and achieving the purpose of improving work efficiency.

[0036] One or more torches can be arranged as required,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com