Apparatus for the preparation of biomass chars returned into field and the recovery and utilization of gas waste heat

A biomass charcoal and waste heat recovery technology, applied in the direction of biofuel, combustible gas purification, combustible gas purification/transformation, etc., can solve problems such as low charcoal yield, equipment that cannot meet its production requirements, secondary pollution, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

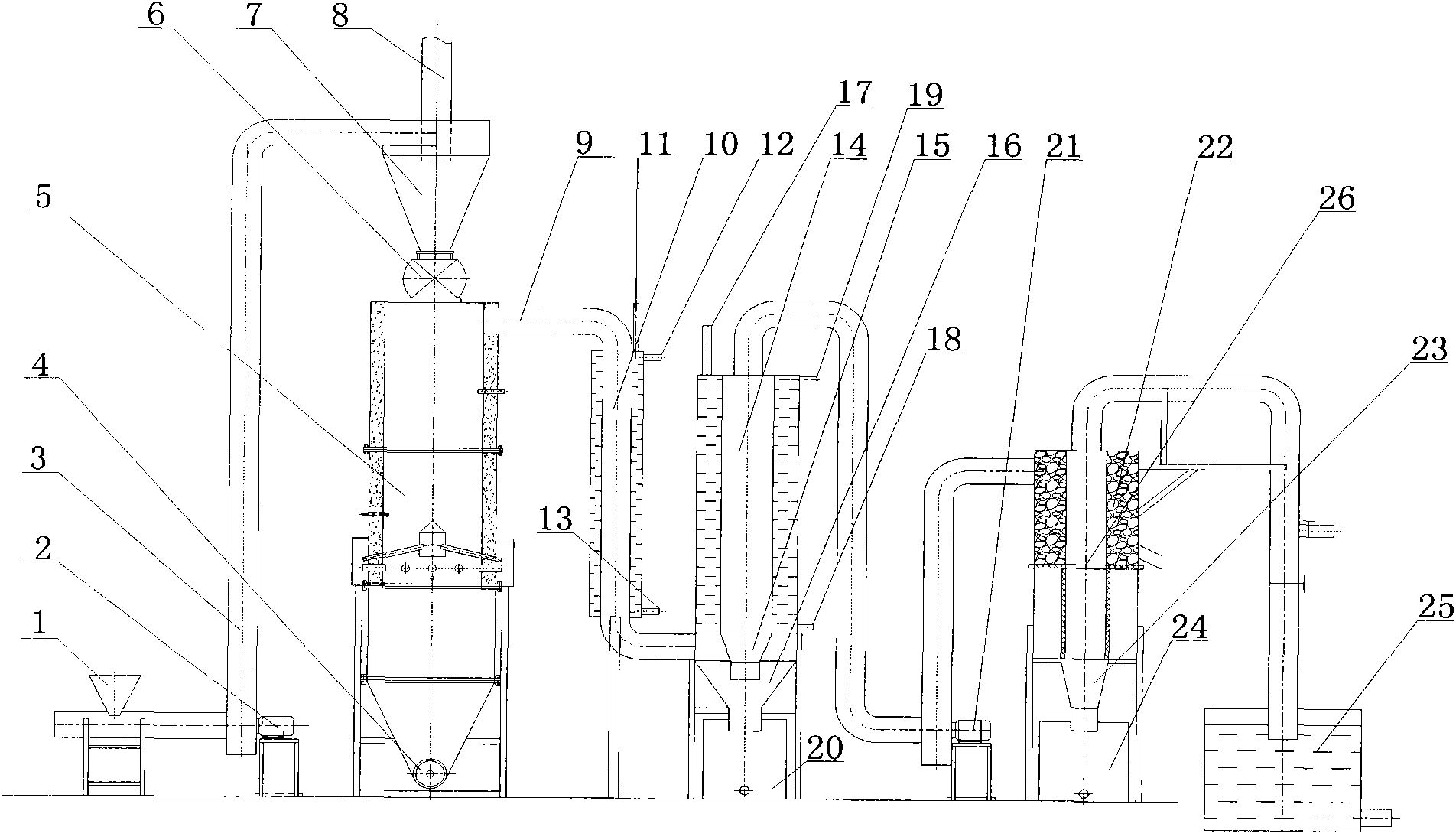

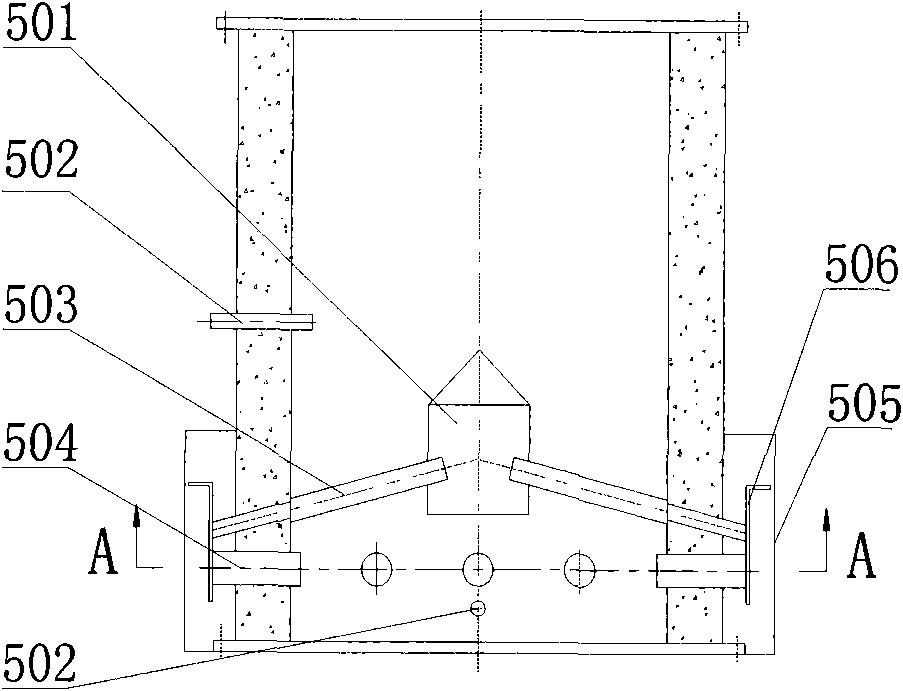

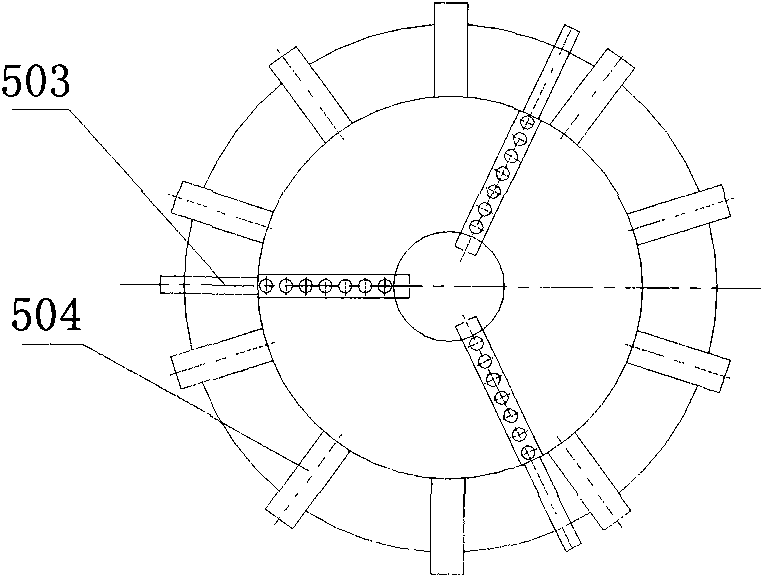

[0022] Reference Figure 1 ~ Figure 3 , The biomass charcoal production and gas waste heat recovery and utilization device used in the field of the present invention includes a pneumatic feeding device connected in sequence through a gas pipe 9, a carbonization furnace 5, a heat exchanger 10, a purifier 14, and a carbon filter 22 And water-sealed flame arrestor 25. among them:

[0023] The pneumatic feeding device is composed of a hopper 1, a fan 2, a conveying pipe 3, a first cyclone separator 7 and a wind shutter 6. In the example shown in the figure, the conveying pipe 3 is a horizontal and a vertical two-section circular pipe. The beginning end of the hopper is connected with the discharge port of the hopper 1, the end of the vertical section enters the first cyclone separator 7 tangentially, and a fan 2 is provided at the intersection of the two circular pipes. The upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com