Internal heating type biomass carbonization furnace capable of recycling flue gas

An internal heating and biomass technology, applied in fixed carbonization furnaces, biofuels, coking ovens, etc., can solve the problems of high energy consumption, no flue gas recycling device, and serious energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

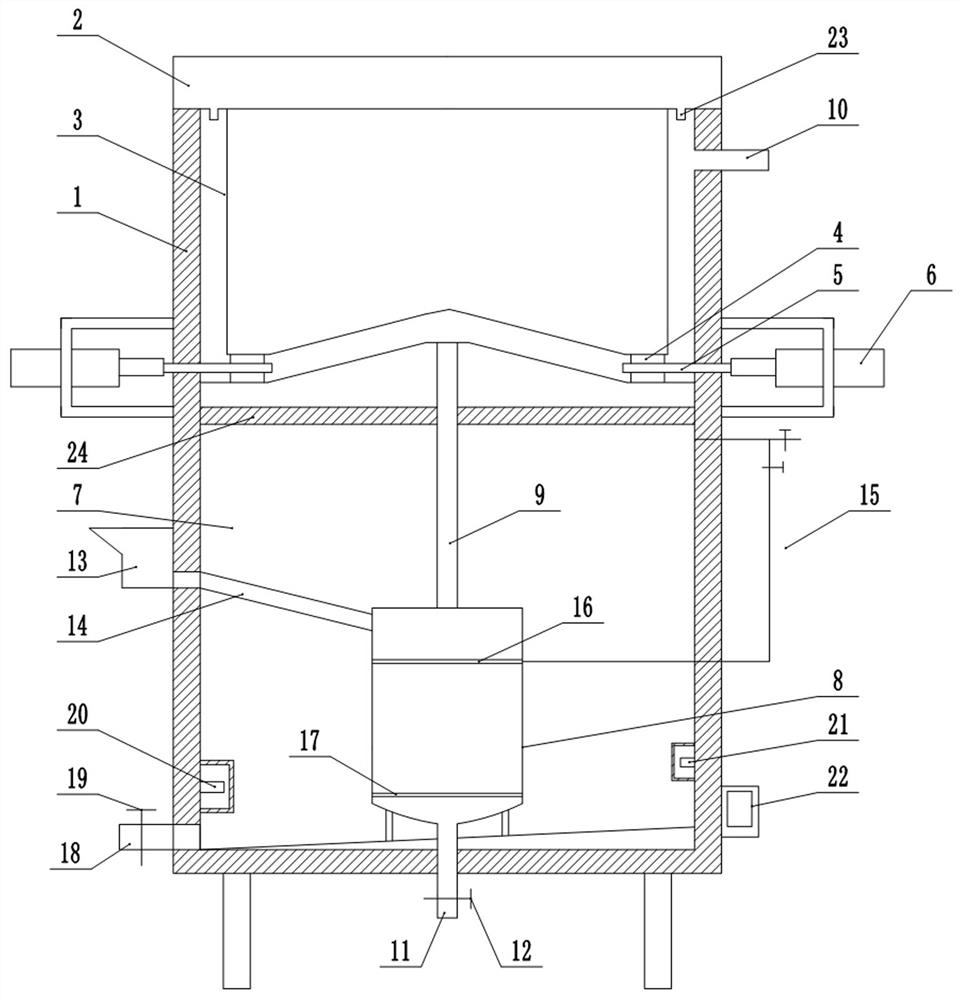

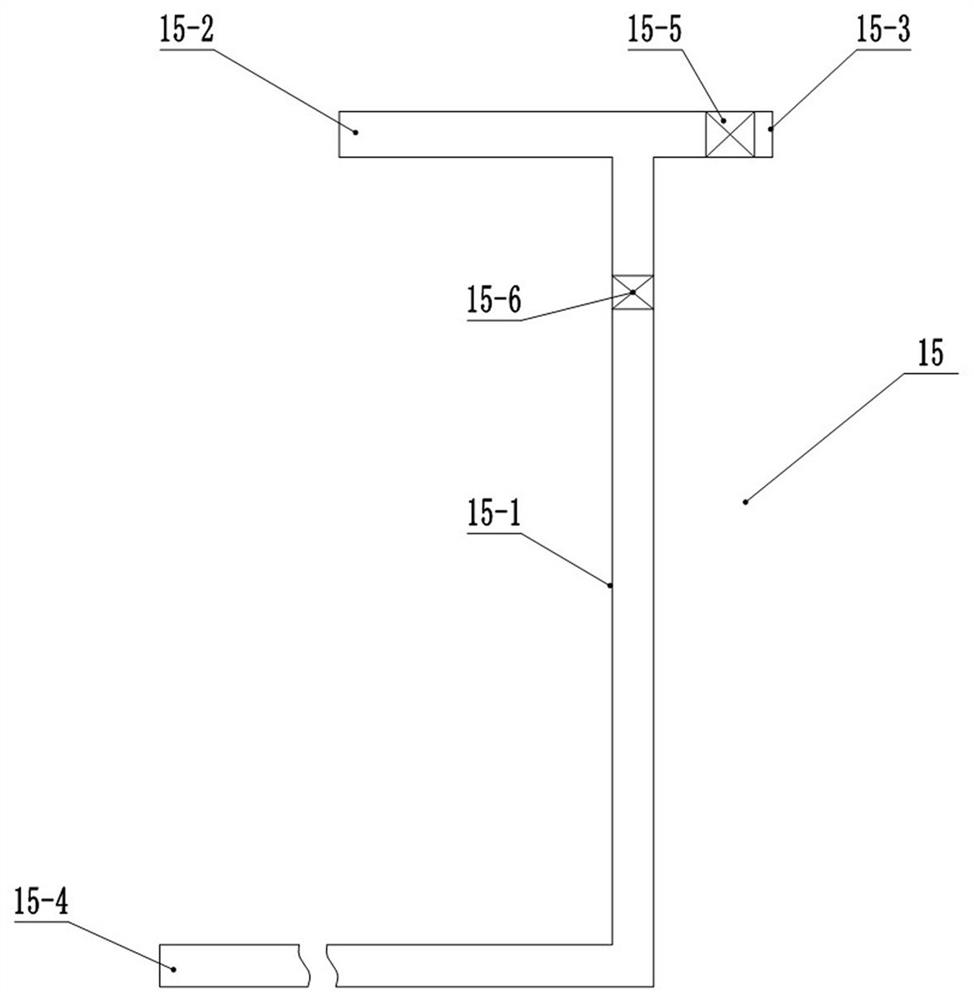

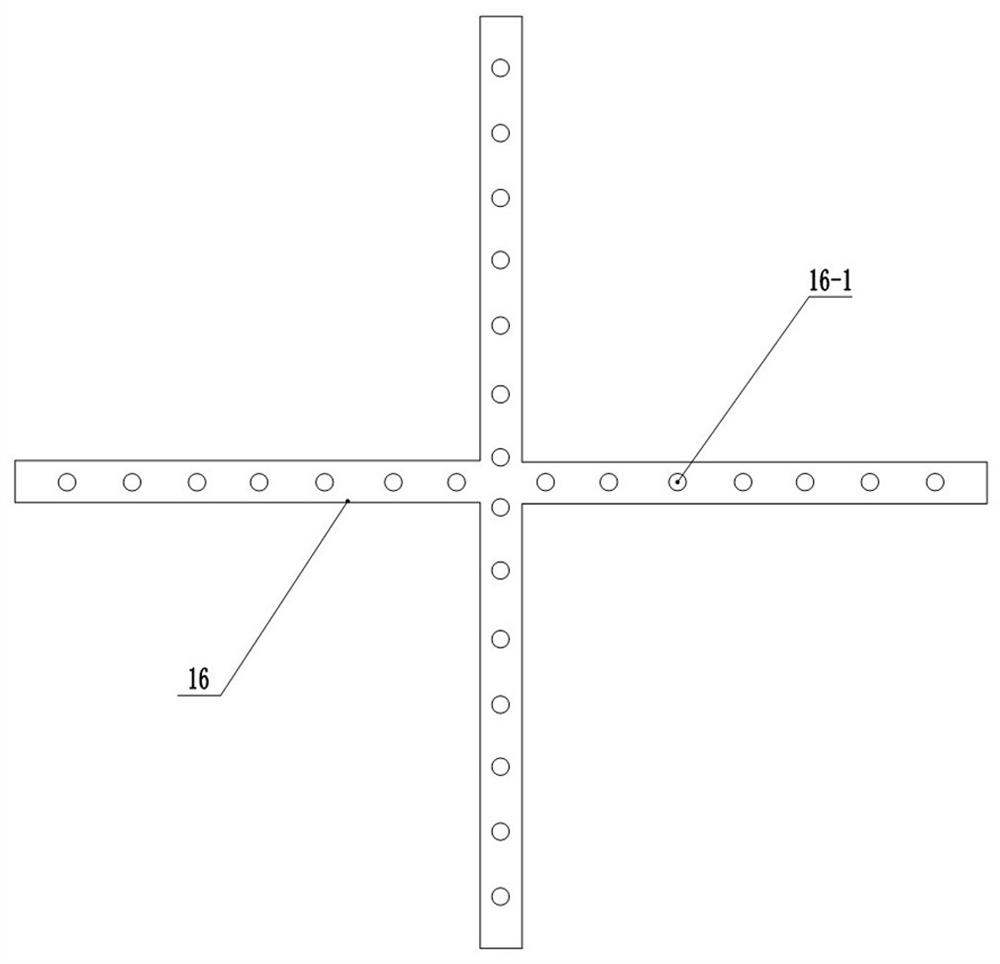

[0022] like Figure 1-Figure 3 As shown, the present invention provides a flue gas reuse internal heat type biomass carbonization furnace, the furnace body 1, the top of the furnace body 1 is provided with a furnace cover 2, and the furnace body 1 is sequentially provided with preset furnaces from top to bottom. The hot box 3, the partition plate and the carbonization chamber 7, the combustion chamber 8 is arranged in the said carbonization chamber 7.

[0023] The side wall of the preheating box 3 is provided with an interlayer, and the interlayer is provided with a smoke exhaust port 10 extending to the outside of the furnace body 1. The bottom of the preheating box 3 is a conical shape that protrudes upwards. A plurality of feeding openings 4 are arranged around, and a shutter 5 is provided at the feeding opening 4, and the shutter 5 is fixedly connected with the telescopic end of the electric push rod 6 arranged on the side wall of the furnace body 1 .

[0024] The top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com