Coal mine mash gas incineration torch

A coal mine gas and torch technology, applied in the field of coal mine gas incineration equipment, can solve the problems of gas emptying, air pollution, equipment personal and property losses, etc., and achieve the effect of protecting mine safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

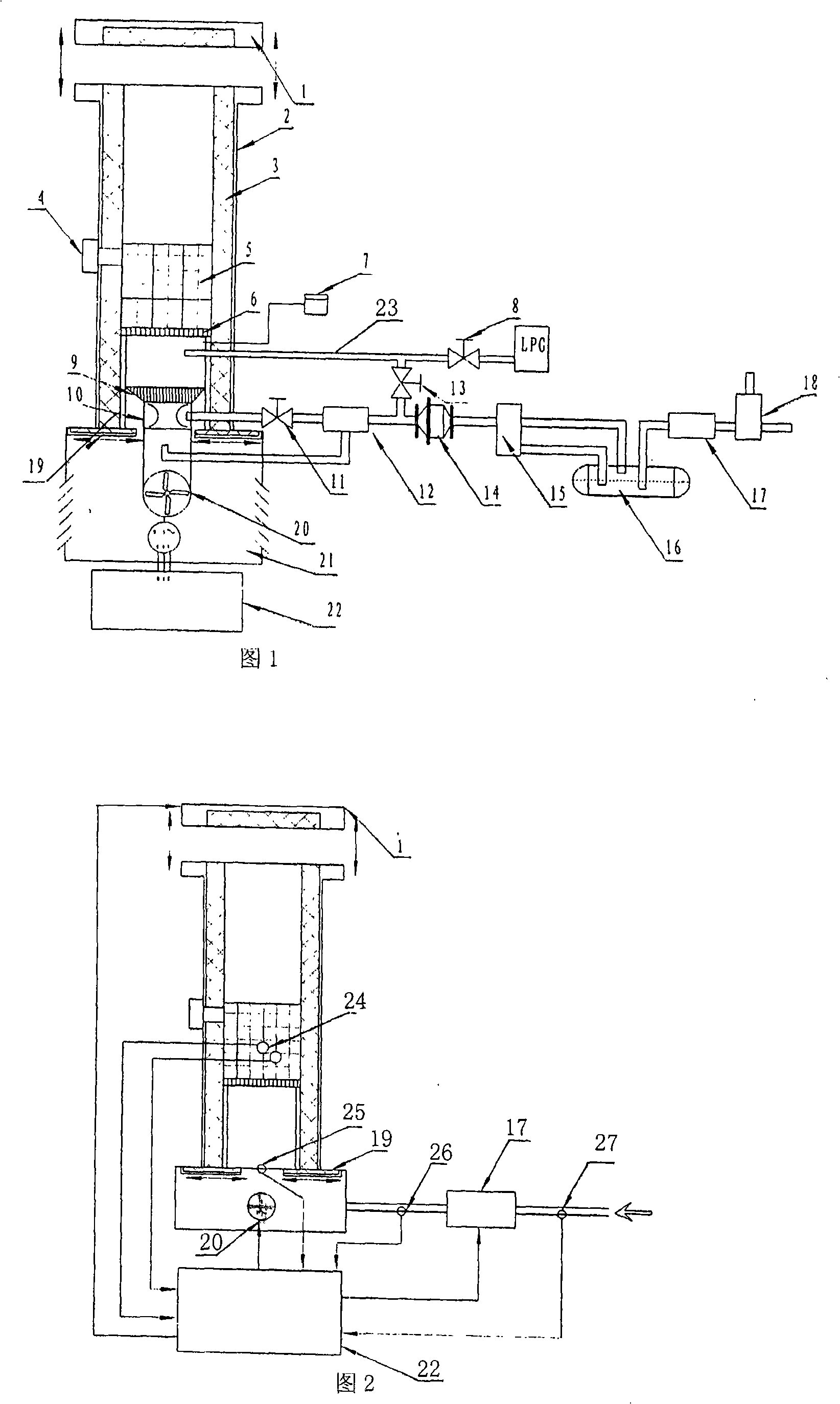

[0012] As shown in Figure 1 and Figure 2, a coal mine gas incineration flare includes a burner, a gas delivery pipeline system, an air supply system, an electronic ignition system and an electrical control system. The burner includes the outer shell 2 and the insulation layer 3 installed inside, the heat storage honeycomb ceramic 5 installed in the middle of the insulation layer and its support 6, the proportional mixer 10 and the multi-head mixed gas nozzle 9 installed at the bottom of the support, and the upper end of the housing 2 The upper sealing cover 1 installed, the lower sealing cover 19 and the base 21 installed at the lower end of the housing 2. The gas delivery pipeline system includes the pipeline connected with the proportional mixer 10, the main gas supply valve 11 and the pressure regulating valve 12, the flame arrester 14, the filter dehydrator 15, the water seal flame arrester 16, the electric control valve 17 and the gas Bleed valve 18. The air supply syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com