Detection system and method for mesomeric state hydrogen gas consumption

A detection system and consumption technology, applied in the direction of weighing, electrical components, measuring devices, etc., can solve the problems of additional readings, inaccurate measurement, etc., and achieve the effect of improving accuracy and convenient research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

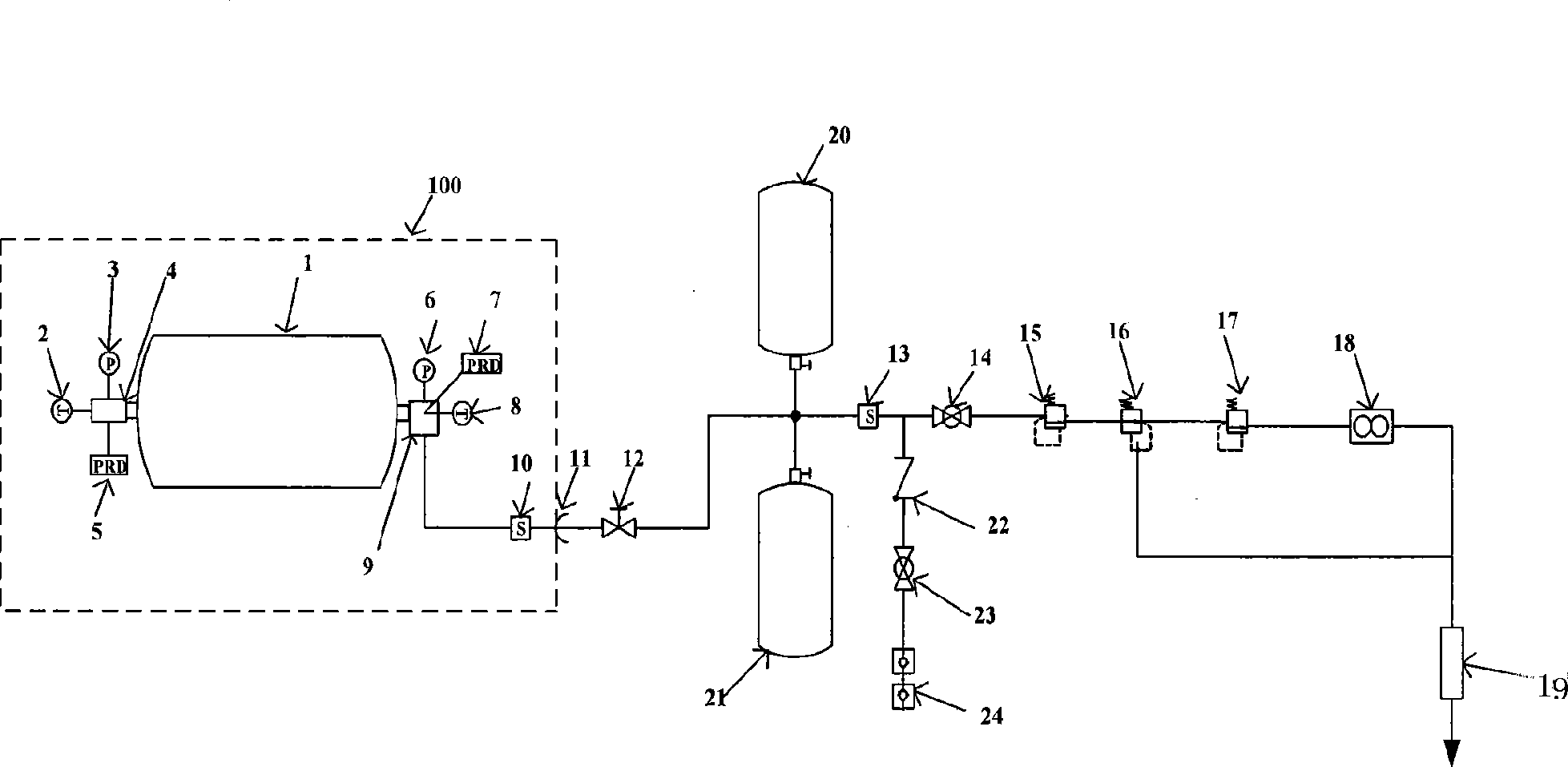

[0057] refer to figure 2 , a steady-state hydrogen consumption detection system, the main line connected with the bottle valve 9 of the high-pressure gas cylinder 1 is sequentially installed with a bottle mouth solenoid valve 10, a ferrule-type joint 11, a detachable pipeline screw valve 12, and a main line Solenoid valve 13, dry manual valve 14, first stage pressure reducing valve 15, safety valve 16, second stage pressure reducing valve 17, flow controller 18 and flame arrester 19; detachable pipeline screw valve 12 and dry circuit Two branch pipelines of hydrogen cylinder 21 and nitrogen cylinder 20 for purging are installed on both sides of the main pipeline between solenoid valves 13; A branch pipeline of a one-way valve 22, a filling pipeline manual valve 23 and a filling interface 24 connected in sequence is installed on the side.

[0058] The cylinder valve 9 of the high-pressure gas cylinder 1 is integrated with a cylinder valve pressure sensor 6, a cylinder valve t...

Embodiment 2

[0071] Such as figure 2 , before connecting the weighing area 100 composed of the high-pressure gas cylinder 1 with hydrogen and the bottle mouth solenoid valve 10 into the hydrogen consumption detection system, first use the electronic balance to weigh the weighing area 100 three times, and record the electronic balance respectively. The three readings are taken and the average value is obtained, and the mass of the weighing area 100 before deflation is 31183.7 grams. After deflation ends and waits for 30 minutes, turn off the power, disassemble the weighing area 100 from the ferrule, and unplug the electrical connection of the sensor on the weighing area 100, and use the electronic balance to weigh it again. The indication of the watch is 31091.6 grams, and the difference between the front and rear indications is 92.1 grams. The weighing area 100 is not removed from the electronic balance, and at the same time, a 50-gram weight, a 20-gram weight, a 20-gram weight and a 3-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com