A manufacturing method of reinforced concrete sandwich beam and its combined sandwich member

A technology of reinforced concrete sandwich core and production method, which is applied in the direction of load-bearing elongated structural components, building components, structural elements, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

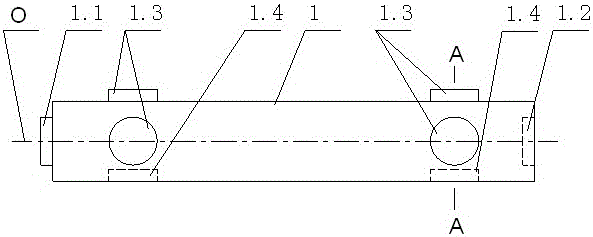

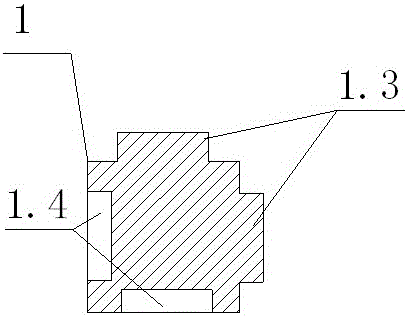

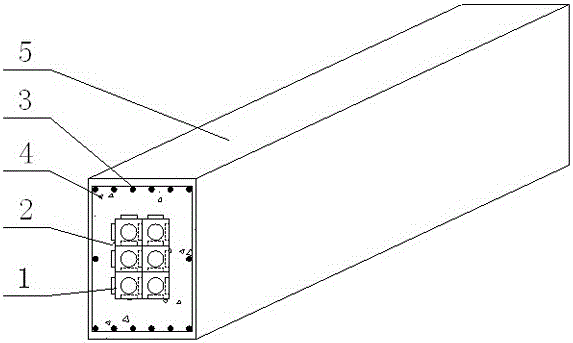

[0023] Embodiments of the present invention: a manufacturing method of a reinforced concrete sandwich beam of the present invention is to use lightweight materials in the production workshop to manufacture a combined sandwich component assembly 1 of uniform specifications, and then the combined sandwich After the component assembly is transported to the construction site, according to the size of the sandwich component of the reinforced concrete sandwich beam to be poured, the combined sandwich component assembly is assembled to obtain the combined sandwich component 2 of the required size. After the composite sandwich member is put into the reinforcement cage 3 in the pouring mold for pouring the reinforced concrete sandwich beam 5 as the sandwich member of the reinforced concrete sandwich beam, the pouring mold is then poured with concrete 4, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com